Movable type positioning detection device

A positioning detection device and movable technology, applied in the direction of claw arms, manipulators, manufacturing tools, etc., can solve the problems of small detection range and waste of man-hours, and achieve the effects of convenient operation, flexible scanning mode and large detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

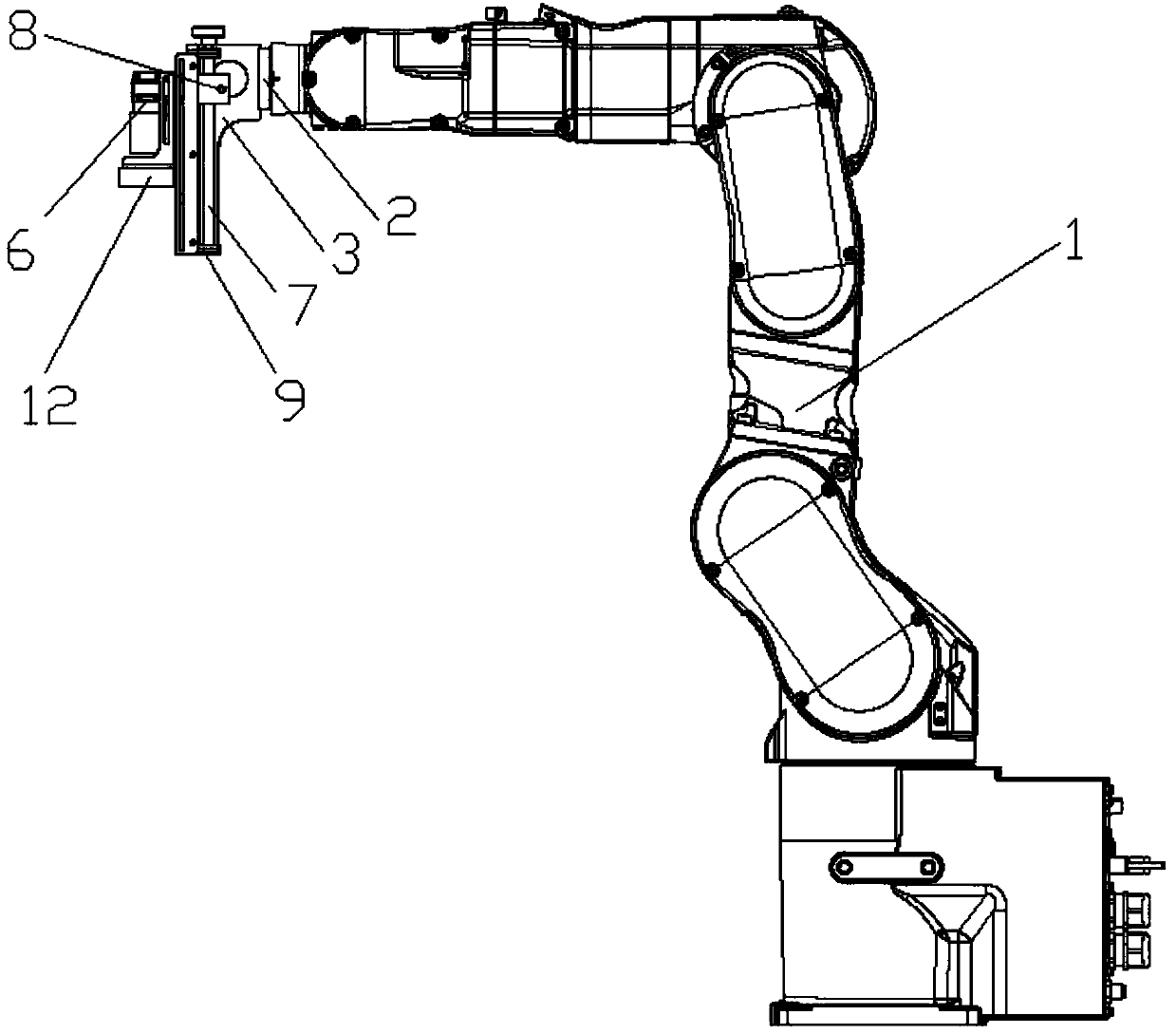

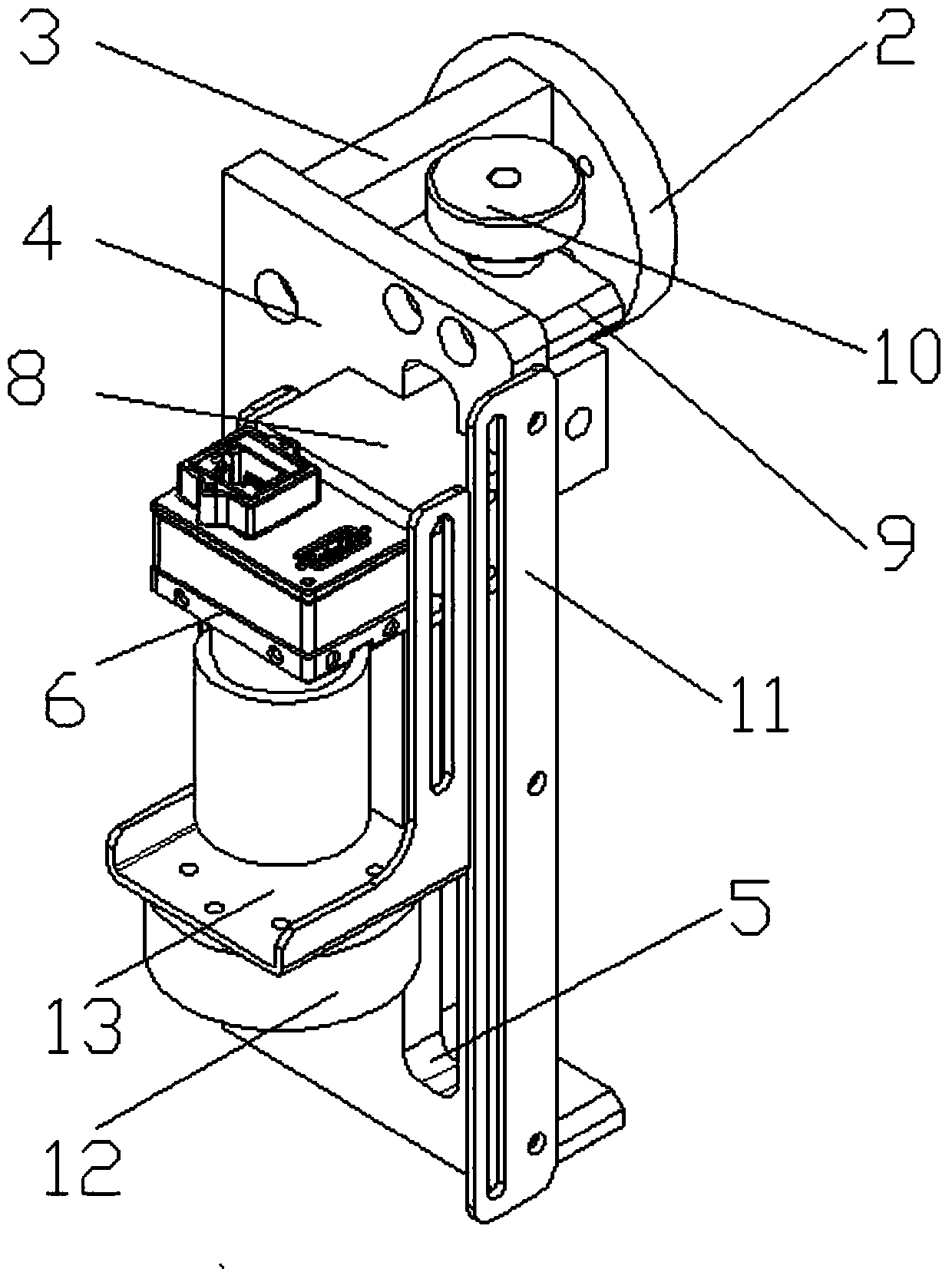

[0013] Such as figure 1 , figure 2 As shown, a movable positioning detection device includes a mechanical arm 1, a main board 3 perpendicular to the flange 2 is installed on the flange 2 of the mechanical arm 1, and the other side of the main board 3 opposite to the flange 2 is A vertical plate 4 parallel to the flange 2 is fixed, and a guide groove 5 parallel to the main board 3 in the longitudinal direction is provided on the vertical plate 4. The camera 6 is arranged on the opposite surface of the vertical plate 4 and the main board 3. The vertical plate 4 and the The contact side of the main board 3 is also provided with an adjustment screw 7, the fixed block 8 passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com