Blower

A technology of blower and direction of air supply, applied in mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problems of low degree of freedom, low rigidity and deformation of shape, and achieve the effect of restraining deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

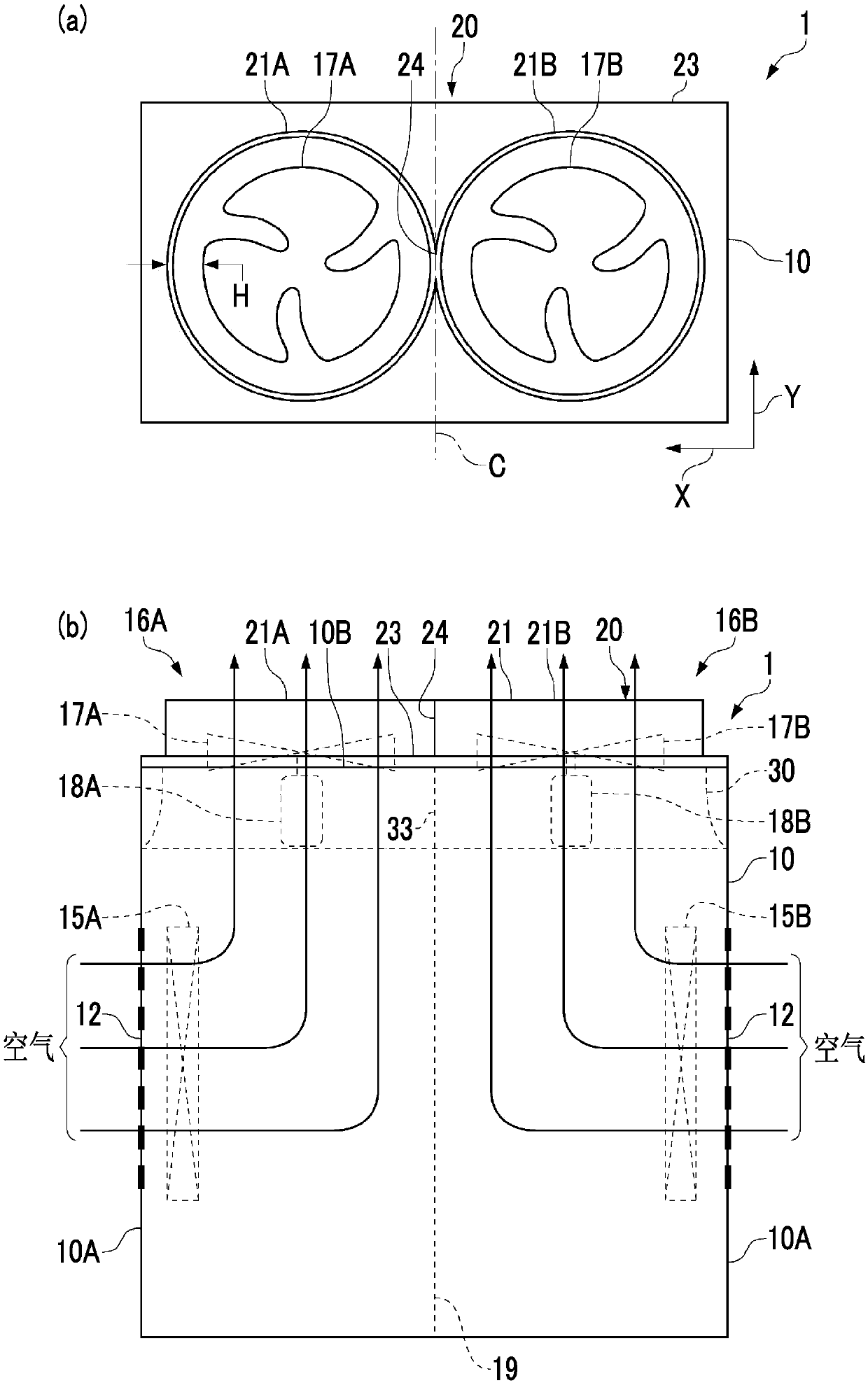

[0032] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

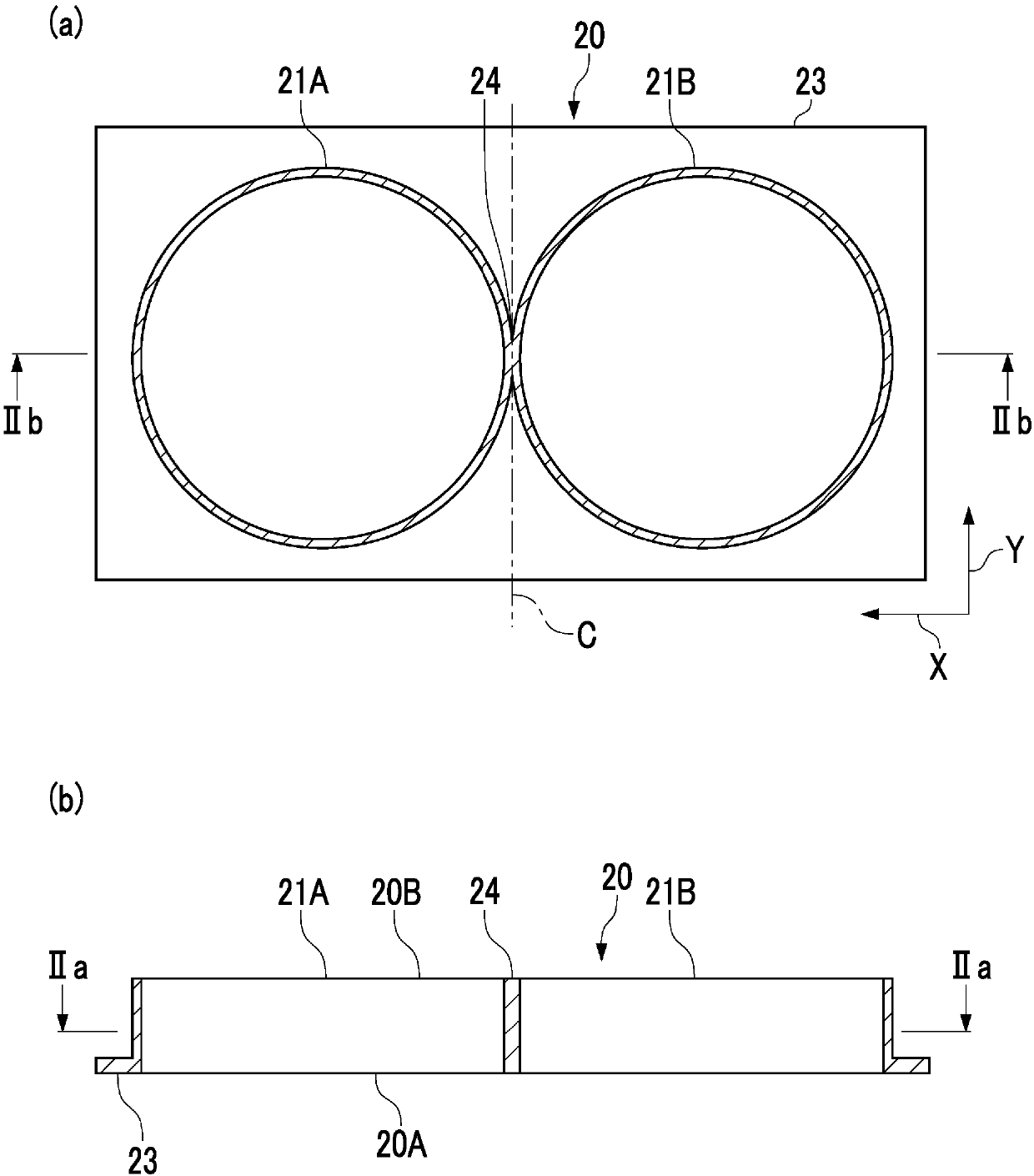

[0033] Such as figure 1 As shown, the outdoor unit 1 of the air conditioner according to the embodiment of the present invention includes a housing 10 in which the suction port 12 is formed on a side surface 10A, a heat exchanger 15 provided inside the housing 10 , and air that has passed through the heat exchanger 15 is discharged. The air blower 16. In addition, although not shown in figure, in this embodiment, the heat exchanger 15 is used as the collective name of heat exchanger 15A, 15B. The same applies to the air blower 16, the fan 17, the electric motor 18, and the like.

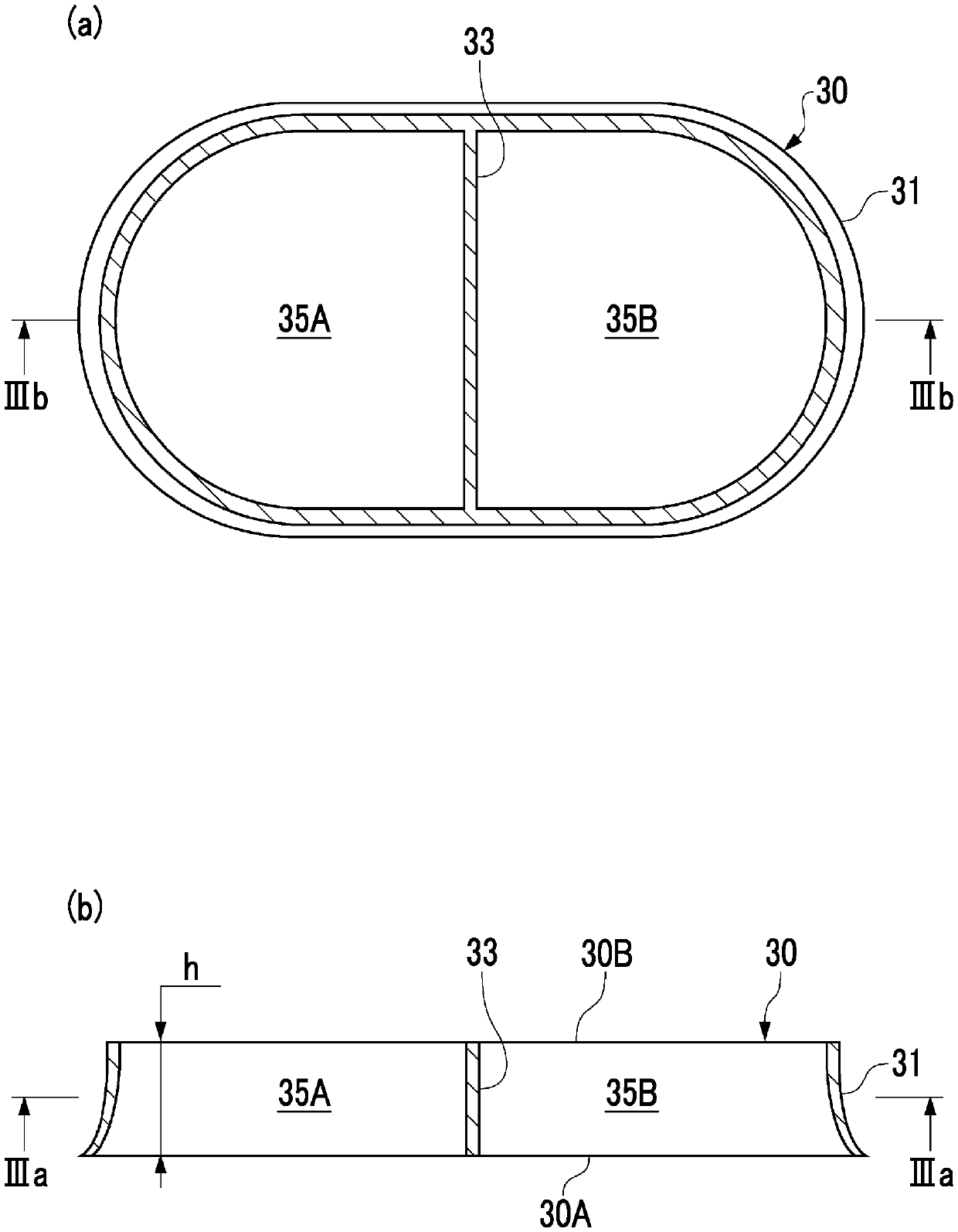

[0034] The air blower 16 includes a fan 17 , an electric motor 18 for driving the fan 17 , a bell mouth 20 for accommodating the fan 17 , and a rectifier 30 provided in a range from the electric motor 18 to the fan 17 .

[0035] If the electric motor 18 is driven, then as figure 1 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com