Digestible substrates for cell culture

A cell culture and substrate technology, applied in cell culture supports/coatings, tissue culture, animal cells, etc., to solve problems such as vaccines that cannot be used for anti-cancer treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Example 1. 1% PGA microbeads cross-linked with 3% calcium.

[0084] Microgalacturonic acid (PGA) solutions were prepared from 1% by weight polygalacturonic acid (PGA) solutions by dissolving polygalacturonic acid sodium salt [Sigma Cat. beads. Filter the solution under vacuum using a 20 micron polypropylene filter to remove particles in suspension.

[0085] A gel bath was prepared using 400 ml of a 3% (w / v) calcium chloride solution in water / ethanol (75 / 25 v / v) in a separate beaker, which was stirred using a magnetic stirrer.

[0086] Droplets were prepared by adding 25 ml of the PGA solution to the gel bath using a syringe fitted with a 30 gauge needle. A syringe pressure of about 2 bar is applied.

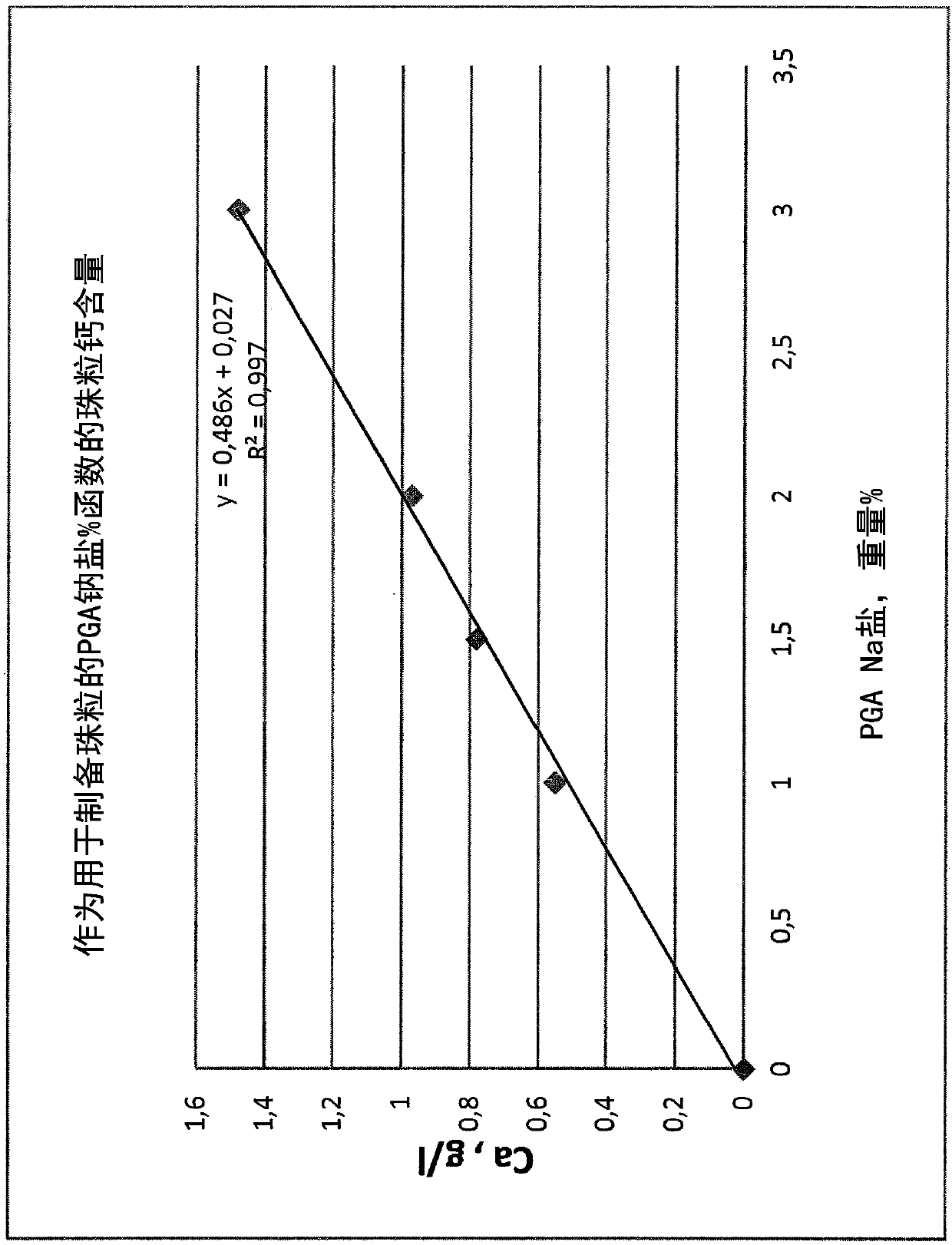

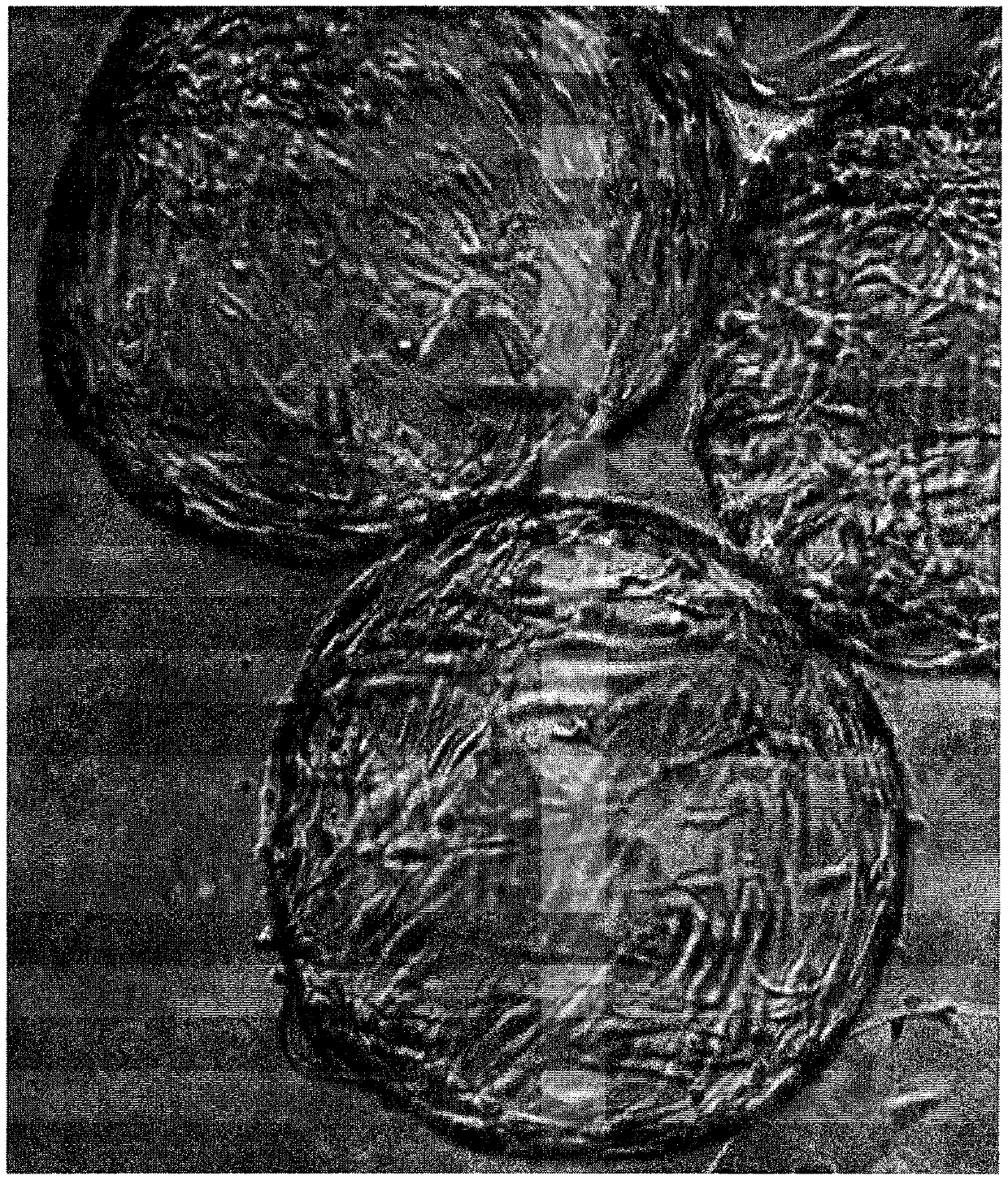

[0087] The beads were hardened in a calcium chloride bath for 120 minutes, followed by four washes with water. The calcium content in the beads was determined as described in Example 9. After four washes, the calcium concentration was about 0.5-0.6 g / l wetted beads....

Embodiment 2

[0090] Example 2. 1% PGA microcarriers cross-linked with 12% calcium.

[0091] The procedure of Example 1 was repeated except that 12% (w / v) calcium chloride in water / ethanol (75 / 25 v / v) solution was used instead of 3% (w / v) calcium chloride in water / ethanol (75 / 25 v / v) solution. After four washes, the calcium concentration was about 0.5-0.6 g / l wetted beads. The beads were highly transparent and free from any observable surface defects.

[0092] When contacted with 5mM EDTA / 50U pectinase at 25°C, the beads completely dissolved within 5 minutes.

Embodiment 3

[0093] Example 3. 1.5% PGA microcarriers cross-linked with 3% calcium.

[0094] The procedure of Example 1 was repeated, except that a 1.5% by weight solution of polygalacturonic acid and a pressure of 4 bar were used.

[0095] After four washes, the calcium concentration was about 0.7-0.8 g / l wetted beads. The beads were highly transparent and free from any observable surface defects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com