Ground surface network cable laying trolley

A trolley and network cable technology, applied in cable laying equipment and other directions, can solve the problems of heavy burden on workers, difficult operation of workers, low efficiency, etc., and achieve the effect of improving efficiency and reducing burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

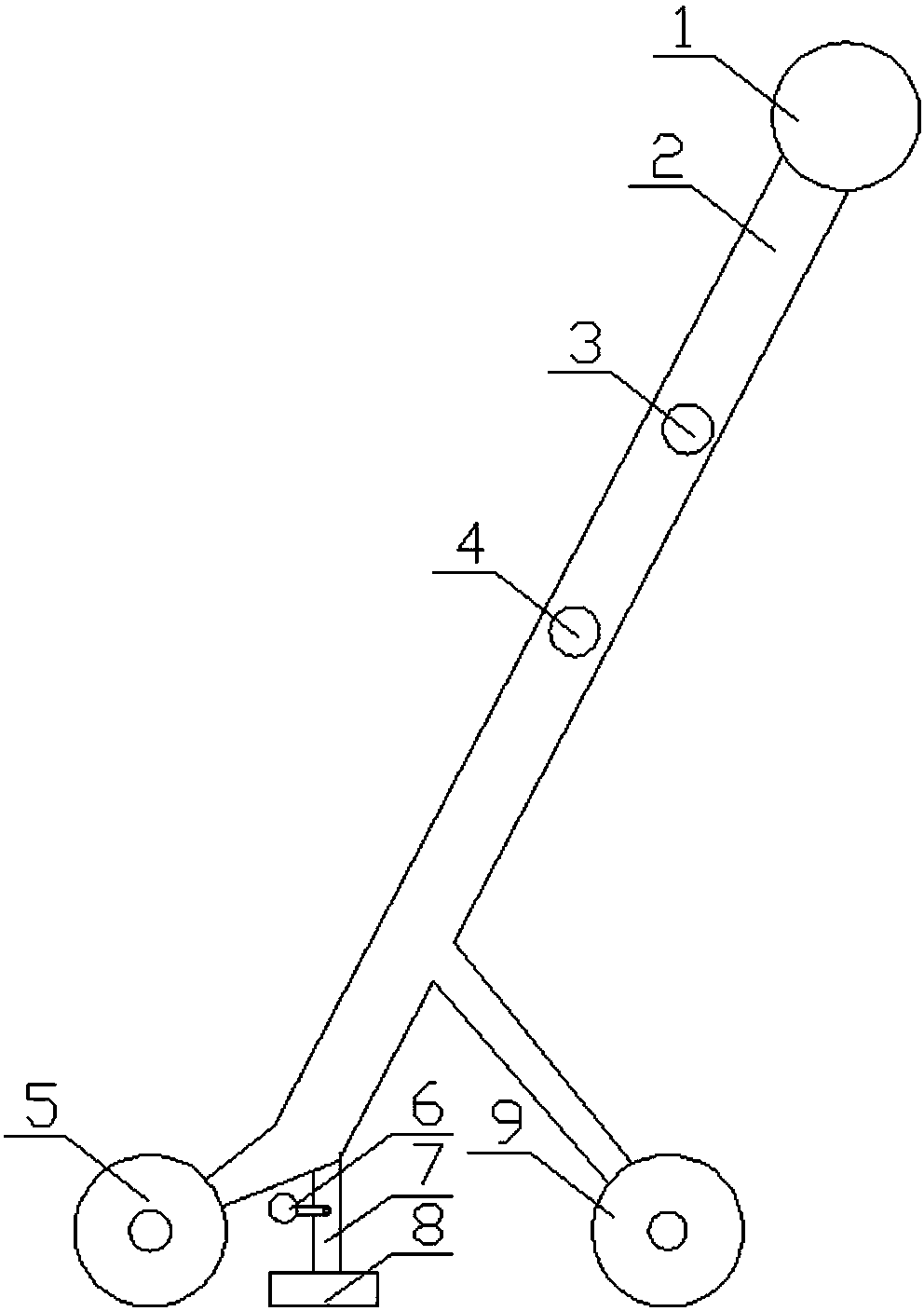

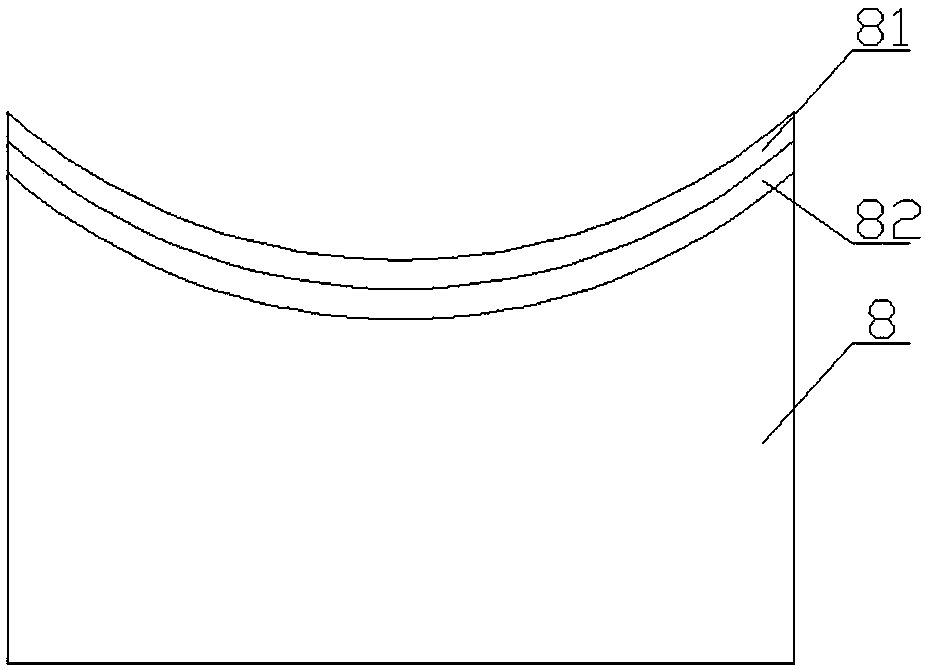

[0018] Such as figure 1 with figure 2 As shown, the trolley for laying surface network cables includes a handle 1, a connecting rod 2, a first winding pile 3, a front wheel 5, and a rear wheel 9. The connecting rod 2 includes a main rod and an auxiliary rod, and the main rod Handle 1 is set on the top of the main rod, front wheel 5 is set on the bottom of the main rod, one end of the auxiliary rod is connected to the main rod, the other end is connected to the rear wheel 9, the first winding pile 3 is set on the main rod, the first winding Line stake 3 is parallel to the horizontal plane, front wheel 5 and trailing wheel 9 connecting lines are perpendicular to the first coiling stake 3, on the connecting bar 2 between front wheel 5 and trailing wheel 9, be provided with vertical extension rod 7, vertically Straight extension bar 7 is vertical to the horizontal plane, and line-pressing plate 8 is set at vertical extension bar 7 bottoms; The bottom of front wheel 5, rear wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com