Composite screw anchor foundation and construction method thereof

A construction method and the technology of screw anchors, which are applied in the direction of basic structure engineering and construction, can solve the problems of large demand for concrete, limited uplift bearing capacity, and large volume of pottery excavated foundations, so as to reduce the amount of earth excavation and improve The effect of increasing the pulling force and reducing the project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

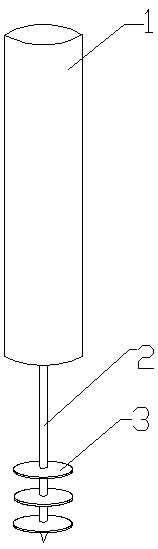

[0018] A composite spiral anchor foundation 1 includes an anchor rod 2, the top or upper part of the anchor rod 2 is provided with a cylindrical foundation 1, and the lower part of the anchor rod 2 is coaxially pierced with a number of circular anchor pieces 3. The number of anchor pieces 3 is at least three, and the distances between adjacent anchor pieces 3 are equal. Both the anchor body and the anchor piece 3 are made of fiberglass composite material. The lower part of the anchor rod 2 is inserted into the hard soil layer or relatively hard soil layer, and the anchor body formed by concrete grouting on the upper part is the pile foundation 1 .

[0019] The construction of the above composite spiral anchor foundation 1 is as follows: firstly, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com