Two-degree-of-freedom high-speed carrying and moving mechanism

A degree of freedom, high-speed technology, applied in the directions of manipulators, conveyor objects, transportation and packaging, can solve the problems of insufficient longitudinal stiffness and insufficient stability, and achieve the effects of good longitudinal stiffness, simple structure and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

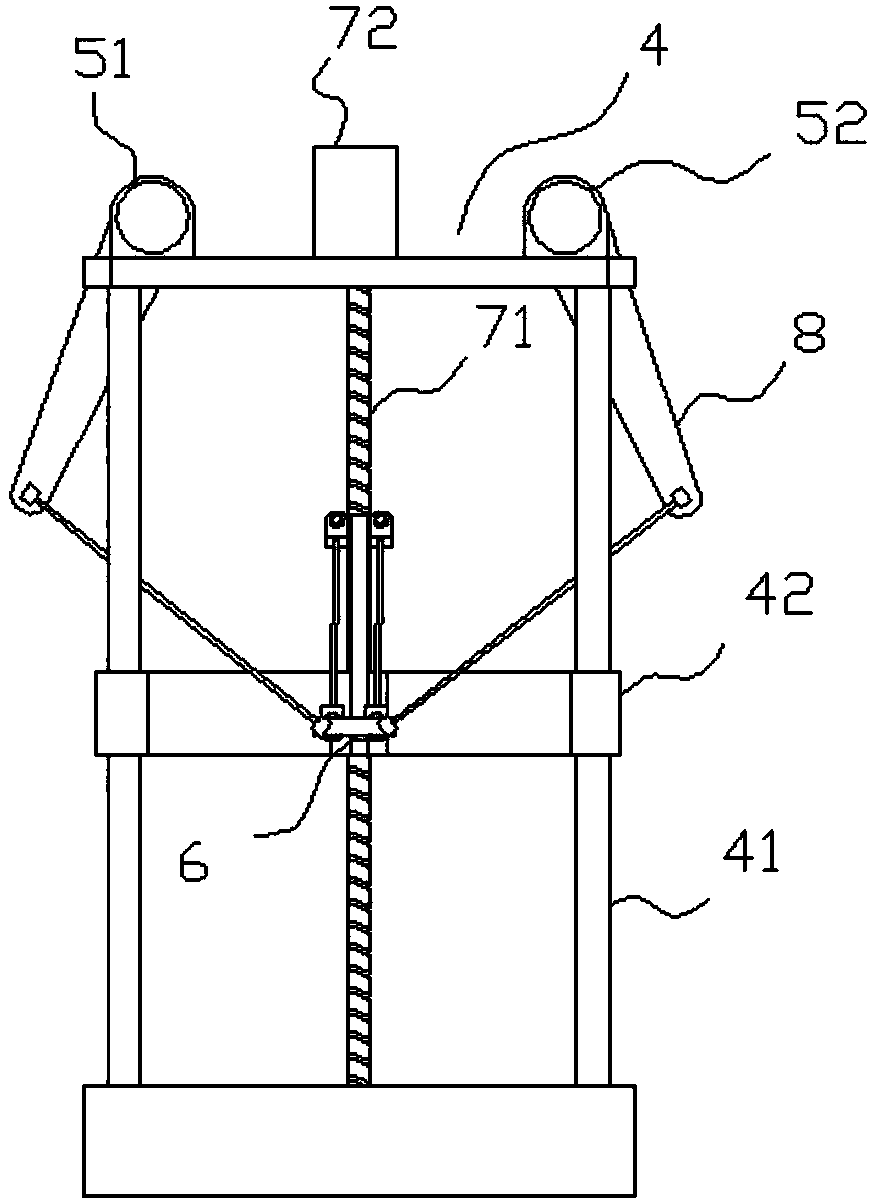

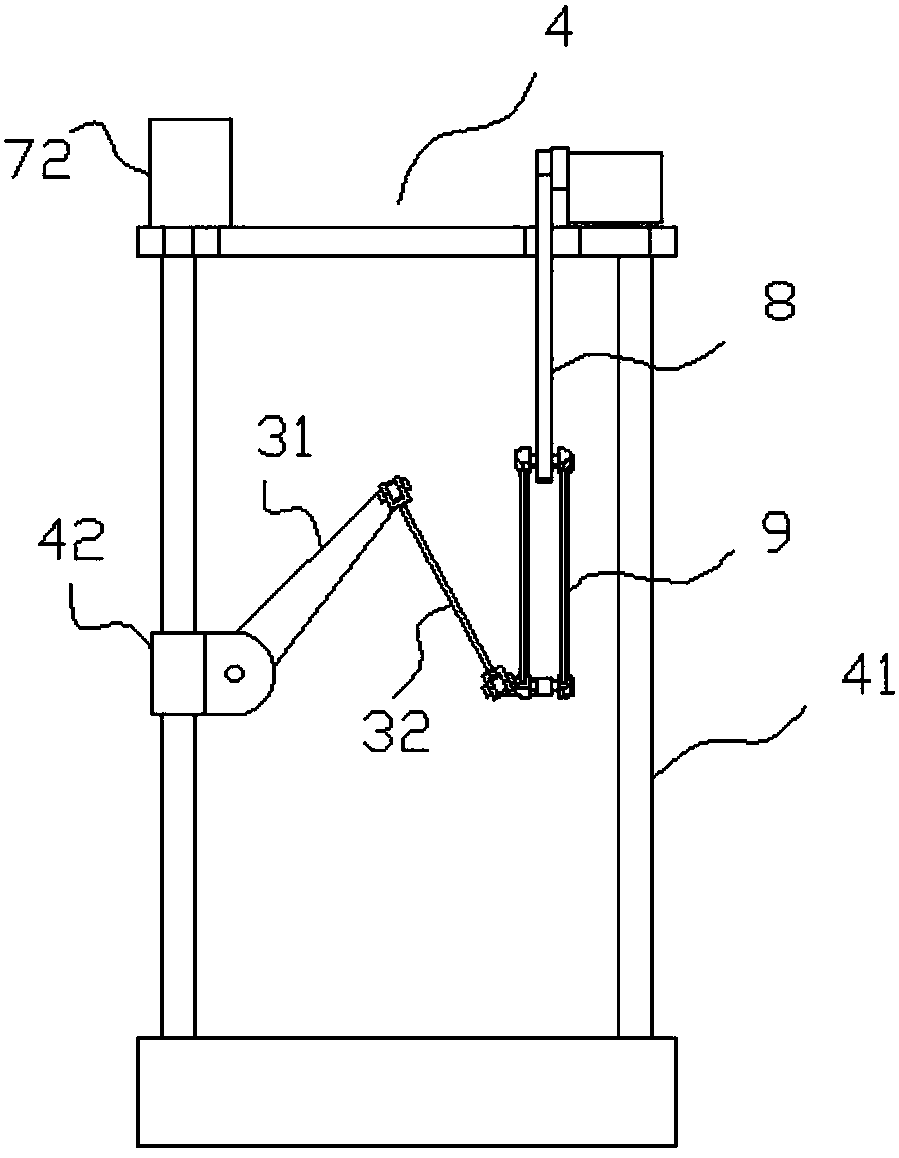

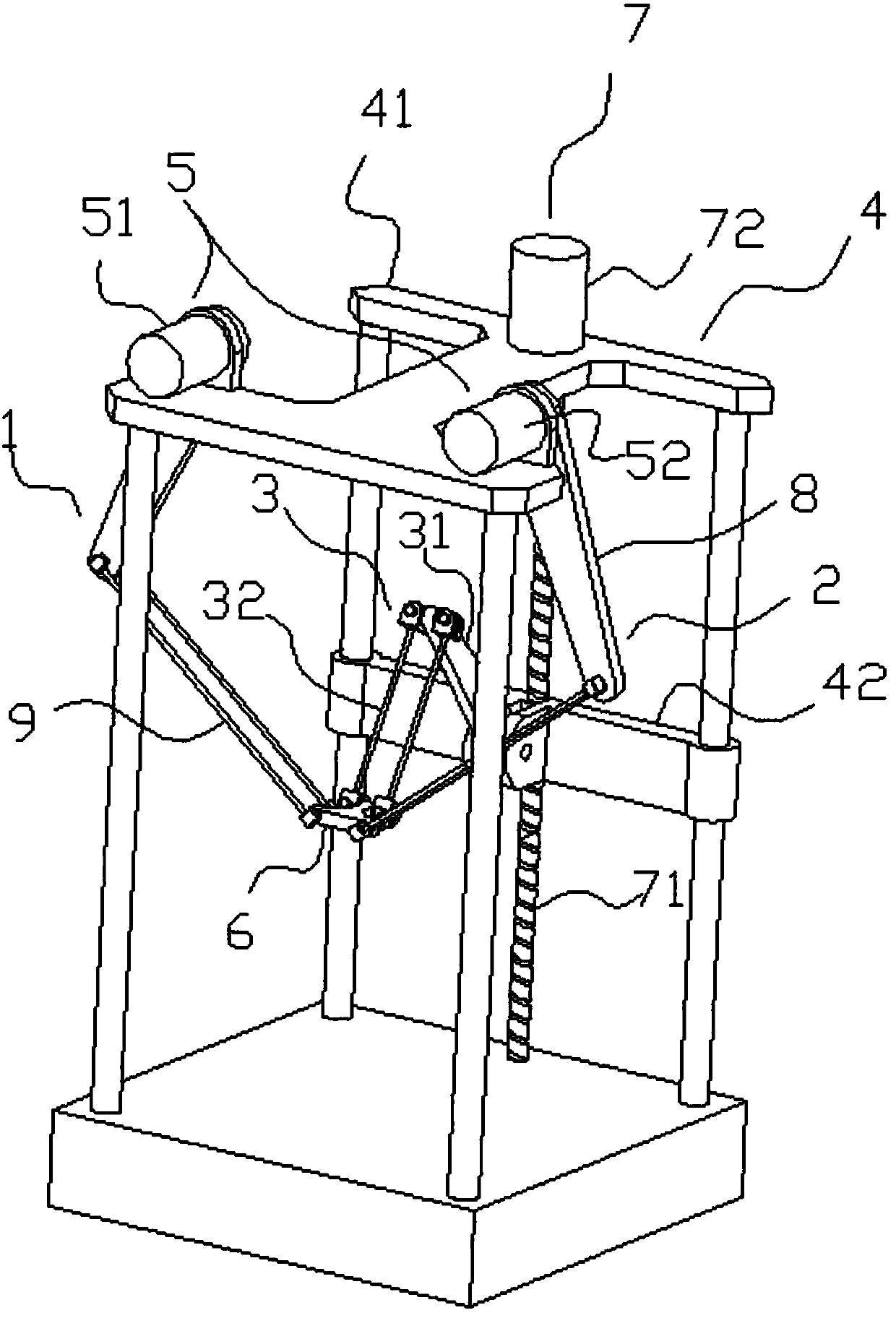

[0028] Such as Figure 1 to Figure 4 As shown, a two-degree-of-freedom high-speed transport and displacement mechanism includes a frame 4, a first branch chain 1, a second branch chain 2, a third branch chain 3, a moving platform 6 and a power unit 5; preferably, the The frame 4 includes a fixed bracket 41 , a movable bracket 42 slidably mounted on the fixed bracket 41 , and a lead screw drive mechanism 7 that drives the movable bracket 42 to slide relative to the fixed bracket 41 . The movable bracket 42 is configured to slide up and down along the fixed bracket 41. The screw drive mechanism 7 includes a screw 71 that is rotatably connected to the fixed bracket 41 at both ends, and a screw drive is provided at one end of the screw 71. The motor 72 , the lead screw 71 runs through the movable bracket 42 , and when the lead screw 71 rotates, the movable bracket 42 moves axially along the lead screw 71 . The first branch chain 1 and the second branch chain 2 are installed on a ...

Embodiment 2

[0038] Such as Figure 5As shown, this embodiment is a further improvement on the basis of Embodiment 1. The specific difference is that the third branch chain 3 is equipped with a power device, which is a third power device 53, and the third power device 53 is fixed on On the movable support 42, its output shaft is connected with the boom 31 of the third branch chain 3 to drive the boom 31 to rotate. When the first branch chain 1 and / or the second branch chain 2 drive the moving platform 6 to move, the third branch chain 1 The power device 53 drives the third branch chain 3 to actively follow the movement of the moving platform 6 . By configuring the driving device on the third branch chain 3, the entire mechanism becomes a redundant drive parallel mechanism, that is, a parallel mechanism with more input components than output components. Compared with ordinary parallel mechanisms, it has higher rigidity and force operation performance. Excellent, large carrying capacity and...

Embodiment 3

[0040] Such as Image 6 As shown, the difference between this embodiment and Embodiment 1 is that the boom 31 is configured to move in a third motion plane, and the third motion plane is set parallel to the horizontal plane. Correspondingly, the large arm 31 of the third branch chain 3 The arm 31 swings in the horizontal direction, and the first movement plane and the third movement plane perpendicularly intersect. The boom 31 is arranged in the third motion plane, which can have different working spaces and improve applicability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com