Double-station screw locking device

A screw locking and double-station technology, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as delay in screw locking, increase labor cost and labor intensity, etc., and achieve improved efficiency, broad market prospects and application prospects , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

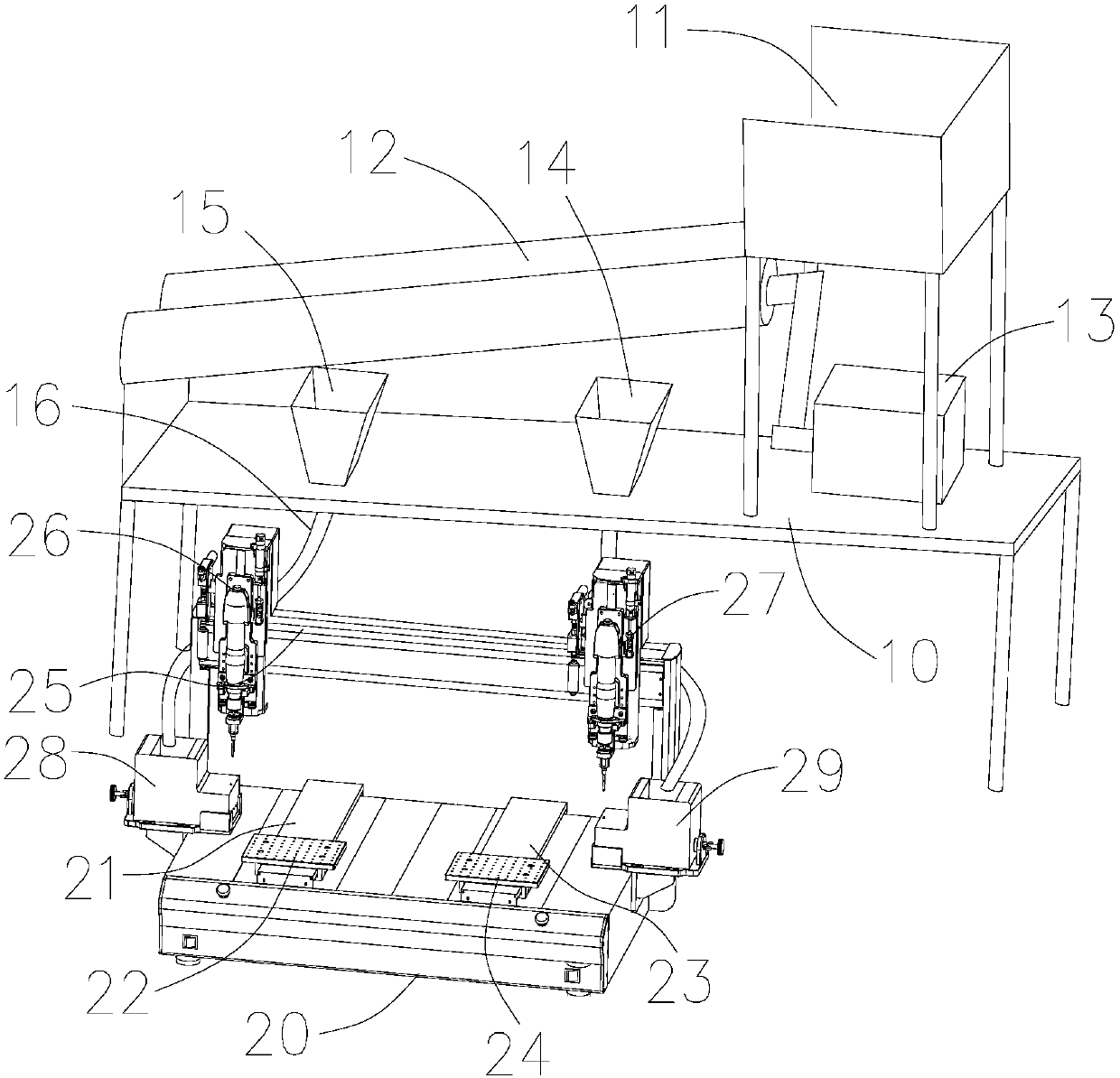

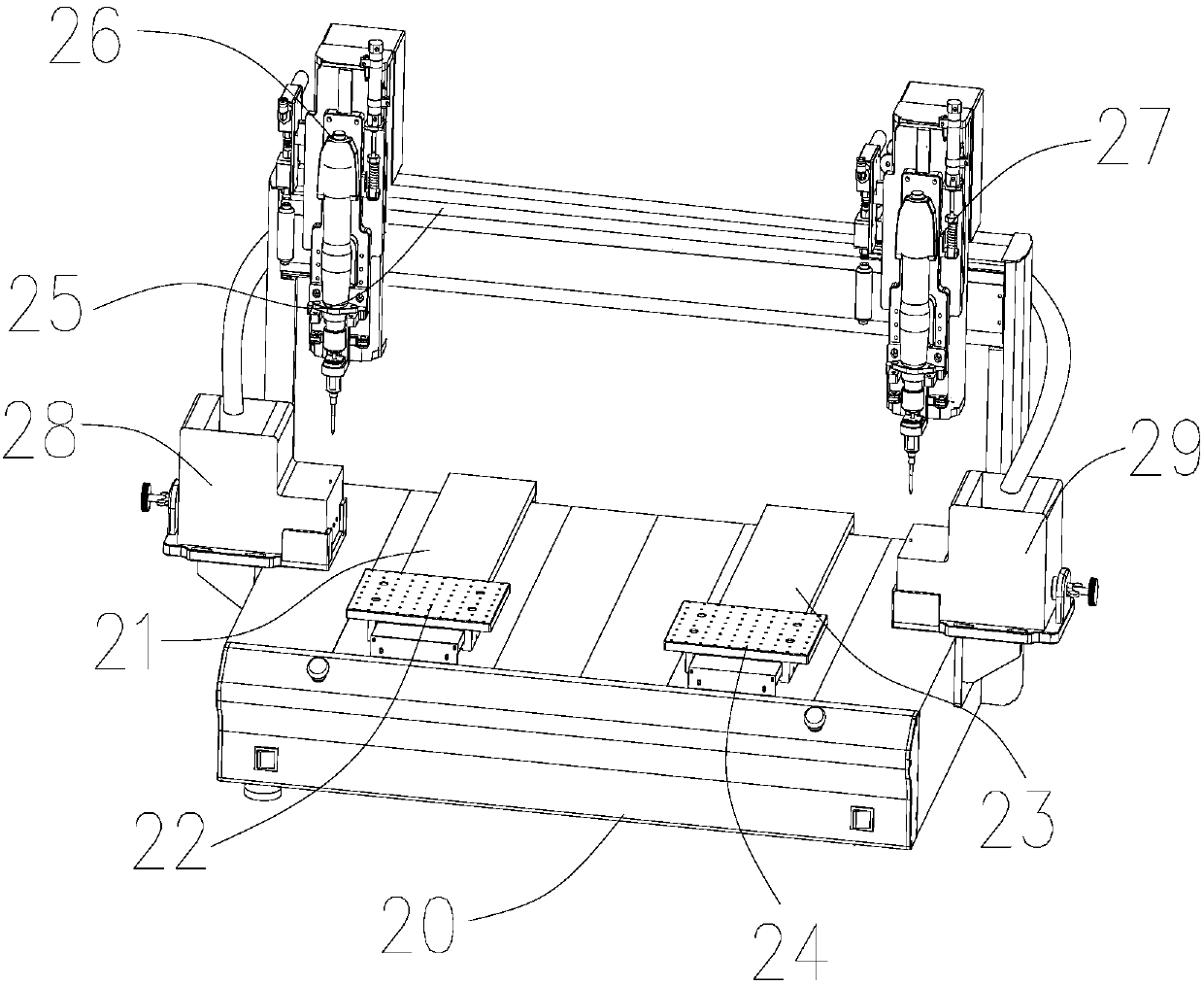

[0017] Such as Figure 1-3 Shown, be the double-station locking screw device of the present invention, comprise screening mechanism installation platform 10 and screw machine installation platform 20, are equipped with unloading chute 11, two screening rollers 12 and rotating motor 13 on the screening mechanism installation platform 10, screening One end of the roller 12 is connected with the discharge trough 11, and the rotating motor 13 is connected with the screening roller 12. The rotating motor 13 controls the rotation of the screening roller 12, and there is a gap between the two screening rollers 12. The size of the gap is adjustable, and the screening roller 12 automatically rotates. One end connected to the chute 11 is inclined to the other end, and the gap gradually becomes larger from the end connected to the chute 11 to the other end, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com