Feed mixing and filtering device

A filter device and mixing device technology, applied in feed, mixer, mixing method, etc., can solve the problems of uneven feed thickness and high impurity content, and achieve the effects of promoting mixing, improving feed quality, and broadening the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

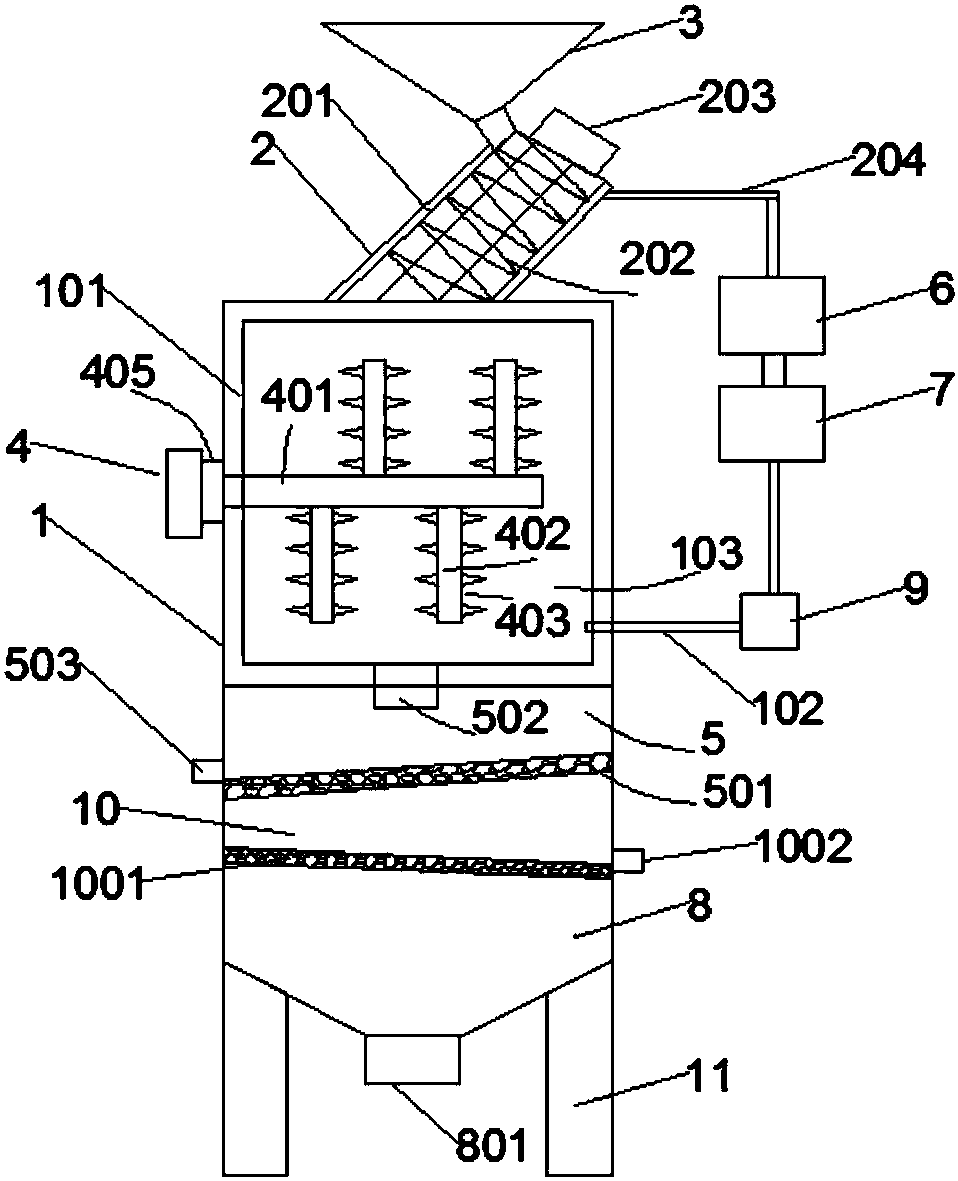

[0016] Such as figure 1 As shown, it includes a feeding device 2, a mixing device 1, a first separation chamber 5, a second separation chamber 10, and a storage bin 8 arranged in sequence from top to bottom, and the feeding device 2 communicates with the mixing device 1, The mixing device 1 is provided with a mixing chamber 103, and a horizontal stirring device is arranged in the mixing chamber 103, and the horizontal stirring device is connected with a speed reducer 405, and the speed reducer 405 is connected with a driving motor 4, and the first separating The top of the chamber 5 is provided with a feeding port 501 communicating with the mixing chamber 103, the bottom of the separation chamber 5 is provided with an inclined coarse filter screen 501, the separation chamber 5 is provided with an impurity outlet 503, and the bottom of the second separation chamber 10 is provided with an inclined A fine filter screen 1001, the second separation chamber 10 is provided with a coa...

Embodiment 2

[0021] On the basis of a feed mixing and filtering device described in Example 1, the feed mixing and filtering device is further optimized. The storage bin 8 is configured as a round table structure, and the mixture outlet 801 is arranged at the middle position of the bottom of the storage bin 8, so that the mixture It is easier to discharge the material, and it also avoids the situation that the feed is deposited in the 8 corners of the storage bin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com