Main circuit topology of artificial zero-crossing technology and current transfer method

A main circuit and current technology, applied in the direction of circuits, electric switches, electrical components, etc., can solve the problems that the inductance of the coil does not increase significantly, slow down the speed of current reduction, and increase the magnetic permeability, so as to improve the reliability of large current breaking performance, increase inductance, and reduce the effect of current change rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

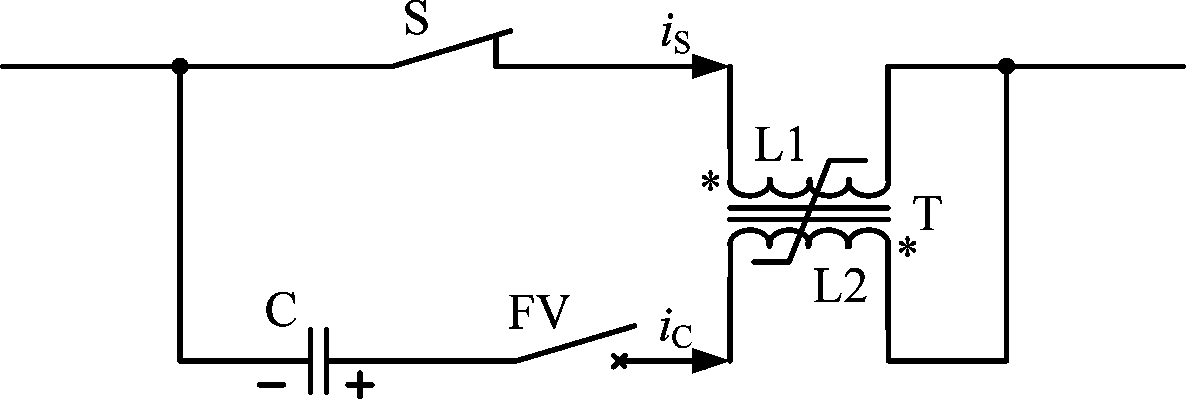

[0020] refer to image 3 As shown, the present invention discloses a main circuit topology of artificial zero-crossing technology, including a parallel main current path and a current transfer circuit. The main current path is composed of a mechanical switch S and a primary coil L1 of a saturated transformer T in series. The current transfer circuit is composed of a pre-charging capacitor C, a control switch FV and the secondary coil L2 of the saturated transformer T in series. The connection terminal of the capacitor C and the mechanical switch S is the pre-charging negative pole.

[0021] The primary coil L1 of the saturated transformer T and the current direction of the same terminal of the secondary coil L2 are opposite, and the turns ratio of the primary coil L1 and the secondary coil L2 is N1:N2, wherein N1>N2, the saturation The transformer T starts t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com