Halogen-free low-smoke protective layer locking type cable for coal mine

A coal mine and locking technology, which is applied in the direction of power cables with shielding layers/conductive layers, insulated cables, power cables, etc., can solve the problems of troublesome protective layers, free movement and setting of wire cores, etc., so as to improve the flame retardant level and avoid Free movement, the effect of improving manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

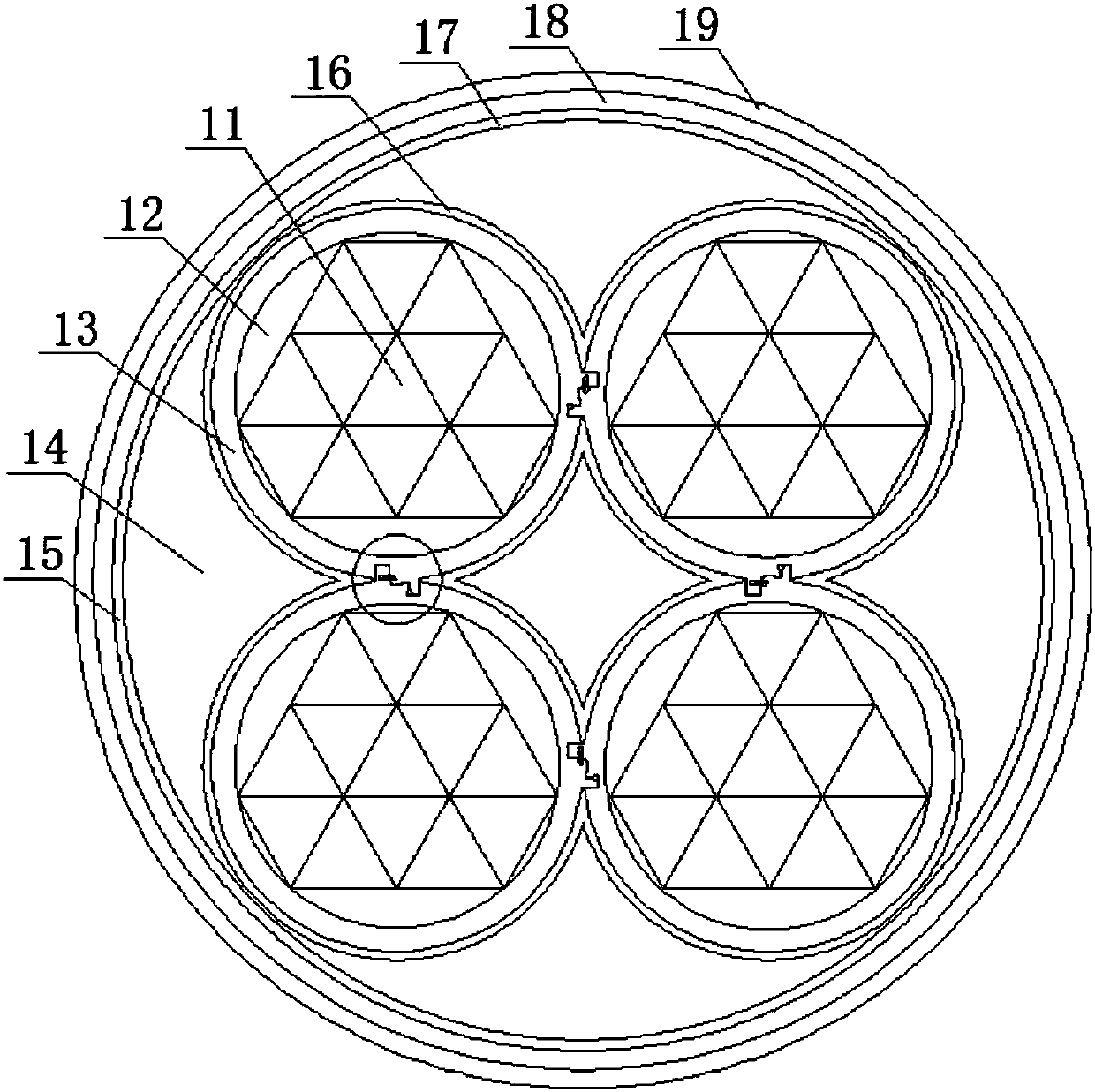

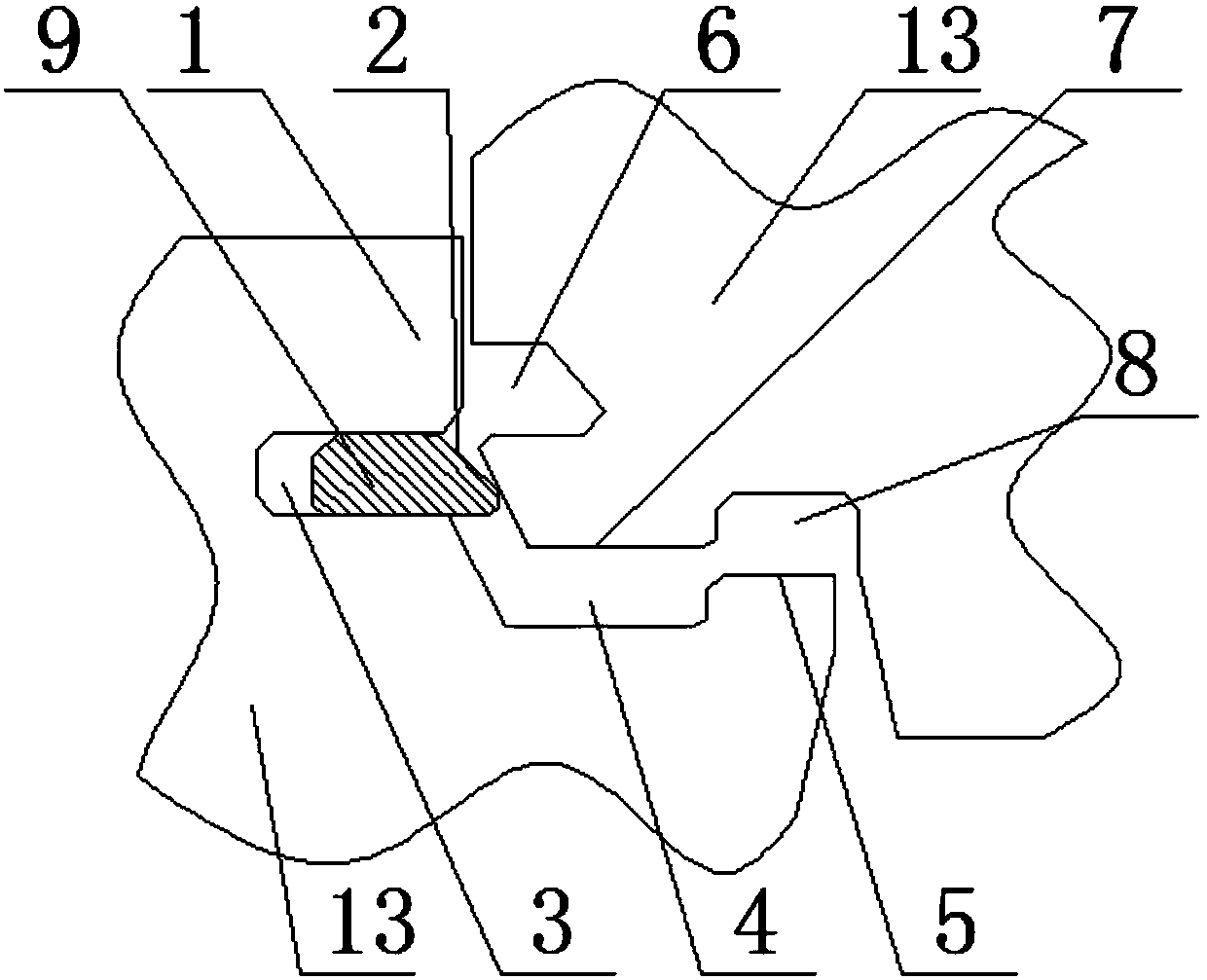

[0020] A halogen-free low-smoke sheathed locking cable for coal mines, the cable includes a cable core composed of multiple wire cores, the cable core is wrapped with a protective layer, and the cable core and the protective layer are filled with a first filling layer , the inner core is protected by a protective layer. Each strand of wire core includes multiple groups of core materials and insulating layers wrapped outside the multiple groups of core materials. Multiple groups of core materials may be distributed around the group core material. Multiple groups of core materials are wrapped with insulating layers, and the gap between the core materials and the insulating layers is filled with a second filling layer, which can cause interference between multiple groups of wire cores through the insulating layers. Of course, an insulating layer can also be provided outside each group of core materials, and the insulating layer on the core material is separated from the rest of ...

Embodiment 2

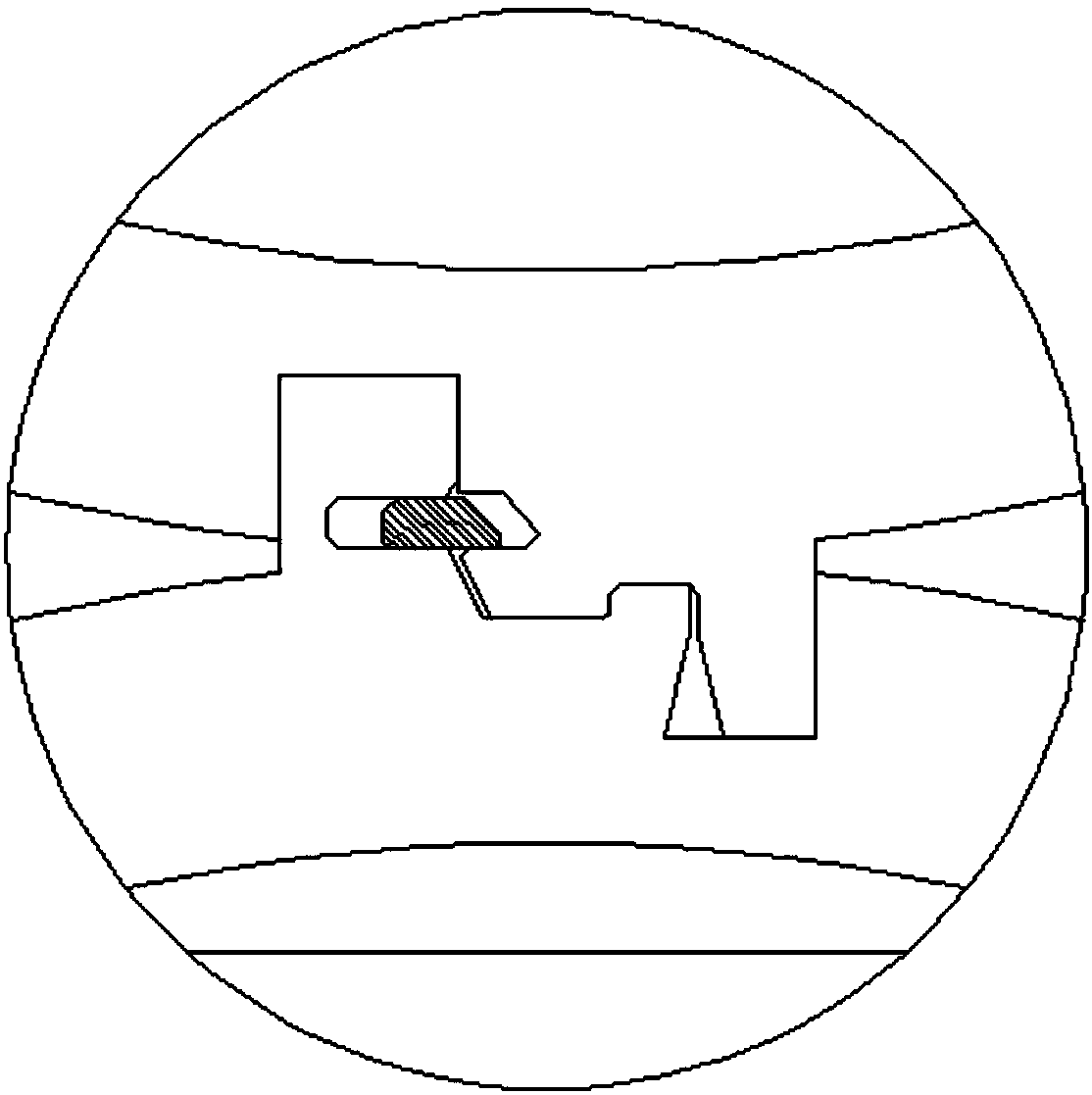

[0024] On the basis of the first embodiment, the outer side of the upper surface of the locking strip is a slope.

Embodiment 3

[0026] On the basis of Embodiment 1 or Embodiment 2, the heights of the first groove-shaped structure and the second groove-shaped structure are equal, and the first groove-shaped structure reaches the outside of the insulating layer where the first groove-shaped structure is located. The distance of the cylindrical surface is equal to the distance from the second groove-shaped structure to the outer cylindrical surface of the insulating layer where the second groove-shaped structure is located, and the depth of the first groove-shaped structure is greater than the depth of the second groove-shaped structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com