Micro-flow calibration device and method of double-channel symmetrical structure

A symmetrical structure and calibration device technology, applied in the field of measurement, can solve the problem of not considering the flow temperature correction of micro-flow measuring instruments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below with reference to the accompanying drawings and examples.

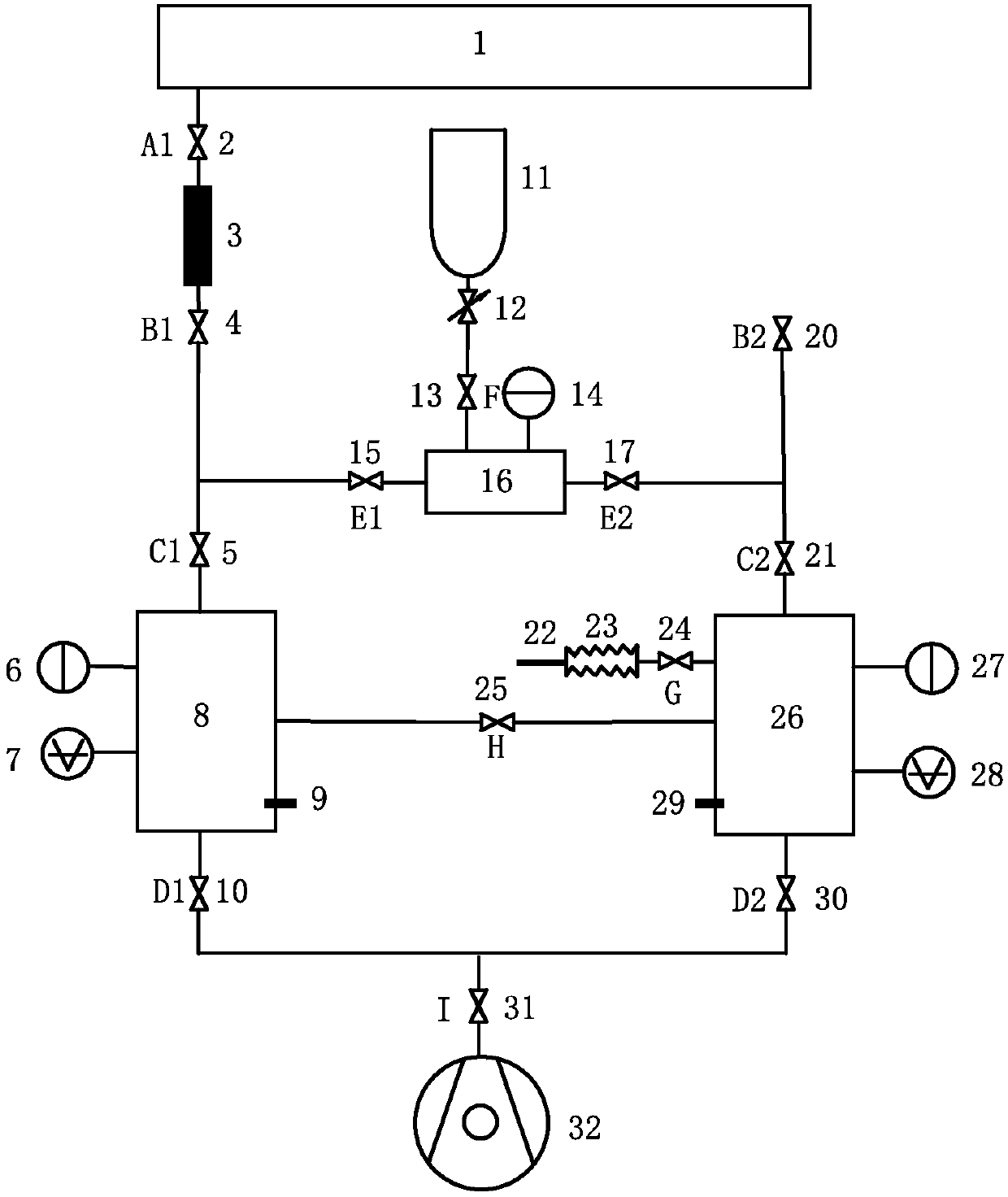

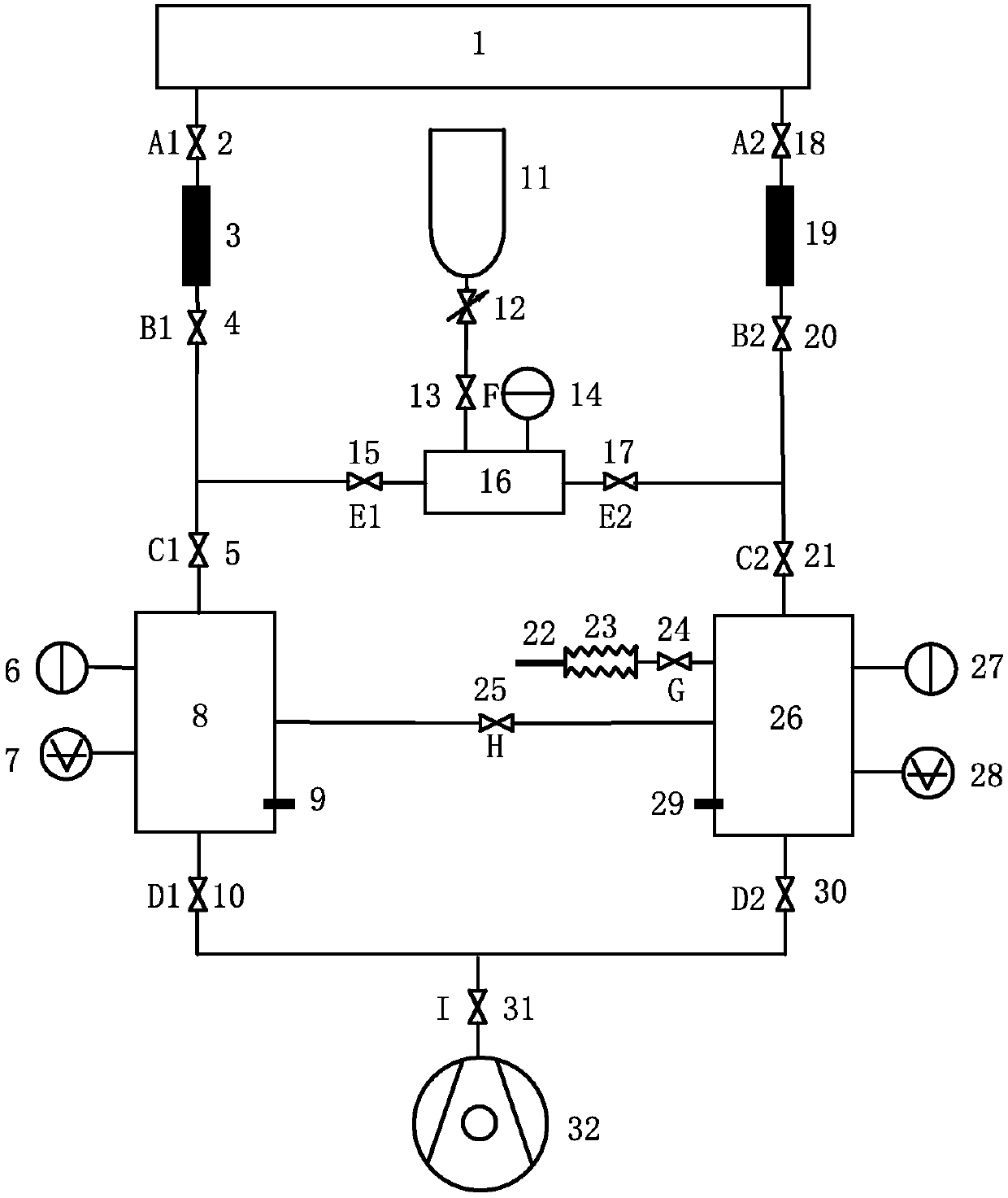

[0049] figure 1 It is a schematic diagram of Embodiment 1 of the micro-flow calibration device with dual-channel symmetrical structure of the present invention, as shown in figure 1 As shown, the device includes:

[0050] The first gas supply system 1 is connected to the calibrated micro-flow measuring instrument 3 through the shut-off valve A1 2 to provide inlet pressure for the micro-flow measuring instrument 3; the second gas supply system 11 is connected to the standard through the series needle valve 12 and the shut-off valve F13 The volume 16 and the standard volume 16 are further connected to the micro-flow measuring instrument 3 through the stop valve E1 15 and the stop valve B1 4 to provide outlet pressure for the micro-flow measuring instrument 3 .

[0051] One end of the flow calibration chamber 8 is connected to the pipeline between the shut-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com