Slag-iron separation method in initial stage of reblowing after long-time damping down of large blast furnace

A separation method and initial slag technology, applied in the field of smelting molten iron, can solve the problems affecting the recovery process of the blast furnace and the high risk of clogging of the skimmer, and achieve the effects of reducing heat consumption, not easy to deform, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

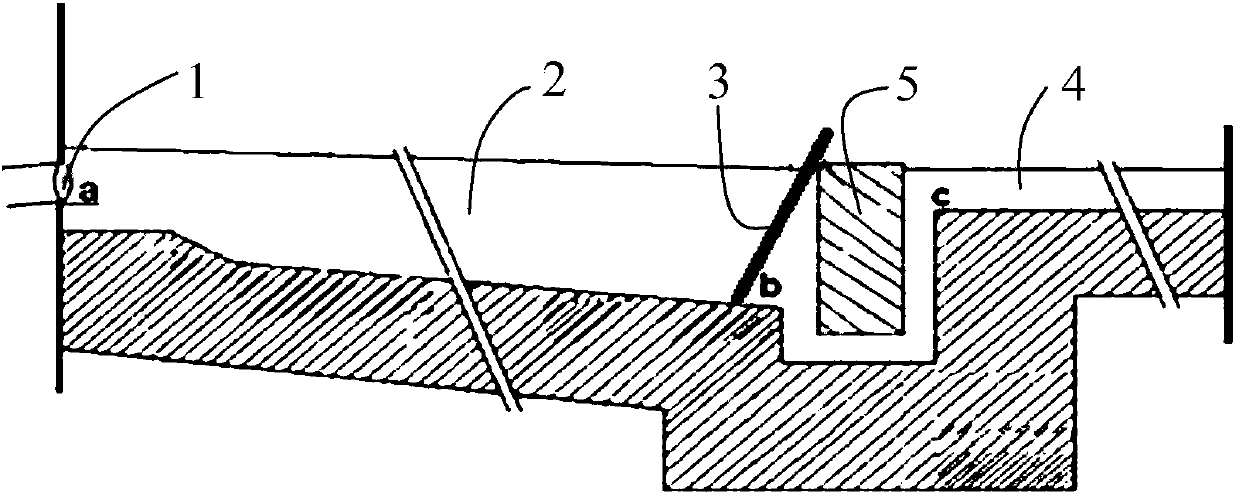

[0038] The method for separating iron and slag at the initial stage of re-airing after a long-term wind shutdown of a large-scale blast furnace in this embodiment includes the following specific steps:

[0039] Step S101. Select a steel plate as the substrate. The steel plate is made of Q235-B or above grade material with a thickness of 10 mm. type, its effective height (the straight-line distance between two points) is 30cm, and the distance between the anchors is 300*300mm, and then the surface refractory material is poured, and the surface refractory material is consistent with the main groove refractory material The thickness of the castable is 50mm, which is a high-alumina castable, forming a baffle, and is dried for use;

[0040] Step S102, select a position 300mm upstream from the entrance of the small pit, insert the baffle into the main ditch obliquely, the inclination angle of the baffle is 60°, the upper part of the baffle leans against the support rod, and the refr...

Embodiment 2

[0045] The method for separating iron and slag at the initial stage of re-airing after a long-term wind shutdown of a large-scale blast furnace in this embodiment includes the following specific steps:

[0046] Step S101, select a steel plate as the substrate, the steel plate is made of Q235-B or above material with a thickness of 12mm, and its width is less than the width of the main groove by 20mm, wherein a number of through holes are opened on the steel plate, and the anchor piece includes a rod body and a nut. The rod body of the anchor passes through the through hole, and there is a nut on each side to fix it. The head of the anchor is Y-shaped, and its effective height (the straight-line distance between two points) is 30cm. The distance between the anchors is 300*300mm , and then cast the board surface refractory material, the board surface refractory material is consistent with the main groove refractory material, the thickness of the board surface refractory material ...

Embodiment 3

[0051] The method for separating iron and slag at the initial stage of re-airing after a long-term wind shutdown of a large-scale blast furnace in this embodiment includes the following specific steps:

[0052] Step S101, select a steel plate as the substrate, the steel plate is made of Q235-B or above grade material with a thickness of 15mm, and its width is less than 15mm of the main groove width, wherein a number of through holes are opened on the steel plate, and the anchor piece includes a rod body and a nut. The rod body of the anchor passes through the through hole, and there is a nut on each side to fix it. The head of the anchor is Y-shaped, and its effective height (the straight-line distance between two points) is 25cm. The distance between the anchors is 300*300mm , and then cast the plate surface refractory material, the plate surface refractory material is consistent with the main groove refractory material, the thickness of the plate surface refractory material i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com