A kind of preparation technology of spherical nano-calcium carbonate

A nano-calcium carbonate and preparation technology, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, calcium/strontium/barium compounds, etc., can solve the problems of low production efficiency, wide particle size distribution, and poor uniformity of nano-calcium carbonate , to achieve the effect of uniform size, shortened reaction time and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Place weighed 60kg of quicklime with an activity of 360mL on the feeding platform of the digester; raise the temperature of 420kg of water to 60°C as digested water; turn on the digester; add digested water to 2% of the effective digestion volume of the digester / 3, add water and quicklime to the remaining water, gradually add to the digester, digest for about 10 minutes, pass through a suspension separator and a 240-mesh circular vibrating sieve to obtain refined milk of lime.

[0024] (2) Adjust the concentration of milk of lime to 8 degrees Baume, and then add the contained CaCO 3 1% industrial white sugar on a dry basis was used as a crystal form control agent to obtain a carbonized initial slurry.

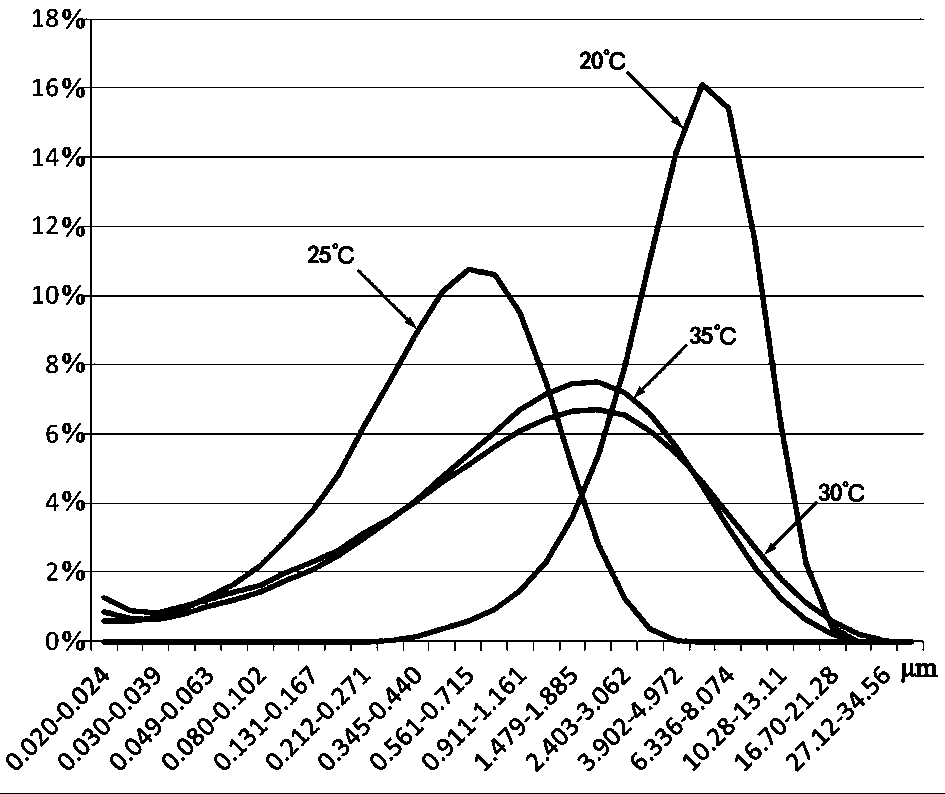

[0025] (3) Put the initial carbonization slurry into an atmospheric jacketed glass reactor, the initial carbonization temperature is 20°C / 25°C / 30°C / 35°C, and the carbonization process is controlled to a maximum of 40°C, The stirring speed is 900r / min, the flow rate...

Embodiment 2

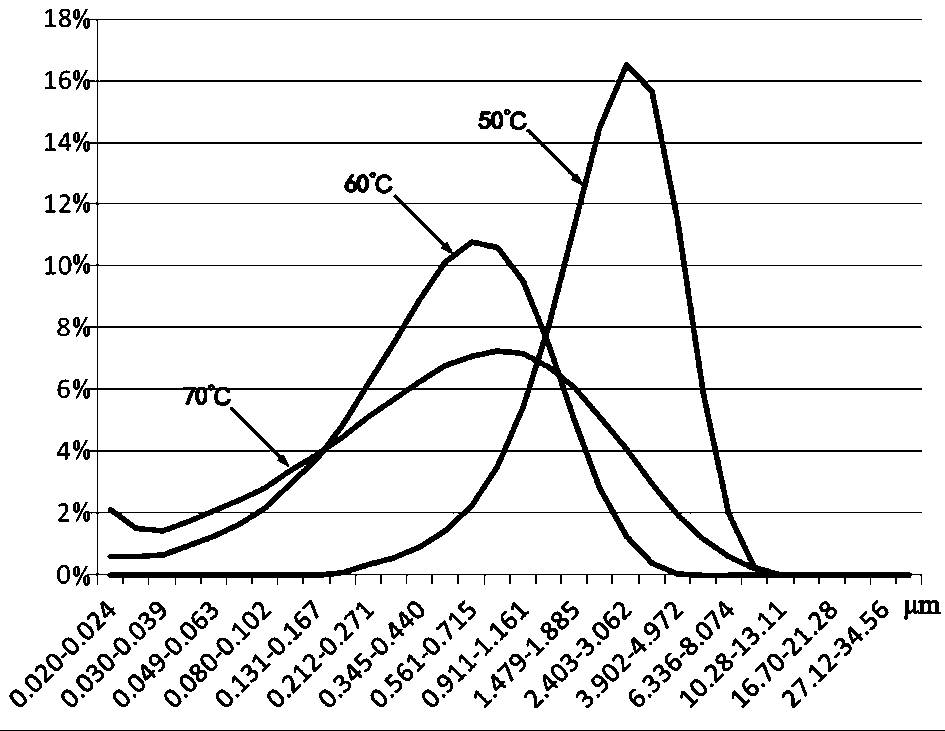

[0031] (1) Place weighed 60kg of quicklime with an activity of 360mL on the feeding platform of the digester; raise the temperature of 420kg of water to 50°C / 60°C / 70°C as digested water; turn on the digester; add the digested water to the digester 2 / 3 of the effective digestion volume of the digester, add the remaining water while adding quicklime, and gradually add it into the digester, digest for about 10 minutes, pass through the suspension separator and 240-mesh circular vibrating sieve to obtain refined lime milk;

[0032] (2) Adjust the concentration of lime milk to 8 Baume degrees, and then add CaCO contained in lime milk 3 1% crystal form control agent (industrial white sugar) of dry mass to obtain carbonized initial slurry;

[0033] (3) Put the initial carbonization slurry into an atmospheric jacketed glass reactor, adjust the initial carbonization temperature to 25°C, the maximum temperature shall not exceed 35°C, the stirring speed is 900r / min, and the flow rate of...

Embodiment 3

[0039] (1) Place weighed 60kg of quicklime with an activity of 360mL on the feeding platform of the digester; raise the temperature of 420kg of water to 60°C as digested water; turn on the digester; add digested water to 2% of the effective digestion volume of the digester / 3 place, add water and quicklime to the remaining water, gradually add to the digester, digest for about 10 minutes, pass through the suspension separator and 240-mesh circular vibrating sieve to obtain refined milk of lime;

[0040] (2) Adjust the concentration of milk of lime to 8 degrees Baume, CaCO 3 1% industrial white sugar crystal form control agent of dry basis quality, gets initial slurry;

[0041] (3) Put the carbonized initial slurry into an atmospheric jacketed glass reactor, the carbonization start temperature is 25°C, the maximum temperature is not more than 35°C, and the stirring speed is controlled at 800r / min / 900r / min / 1000r / min, carbon dioxide (purity 52%) gas flow rate is 3L / min, one-tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com