Disinfection production line for milk-containing beverages

A production line and milk beverage technology, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of low production and processing efficiency and high disinfection costs, and achieve the effects of improving efficiency, simple structure, and convenient operation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

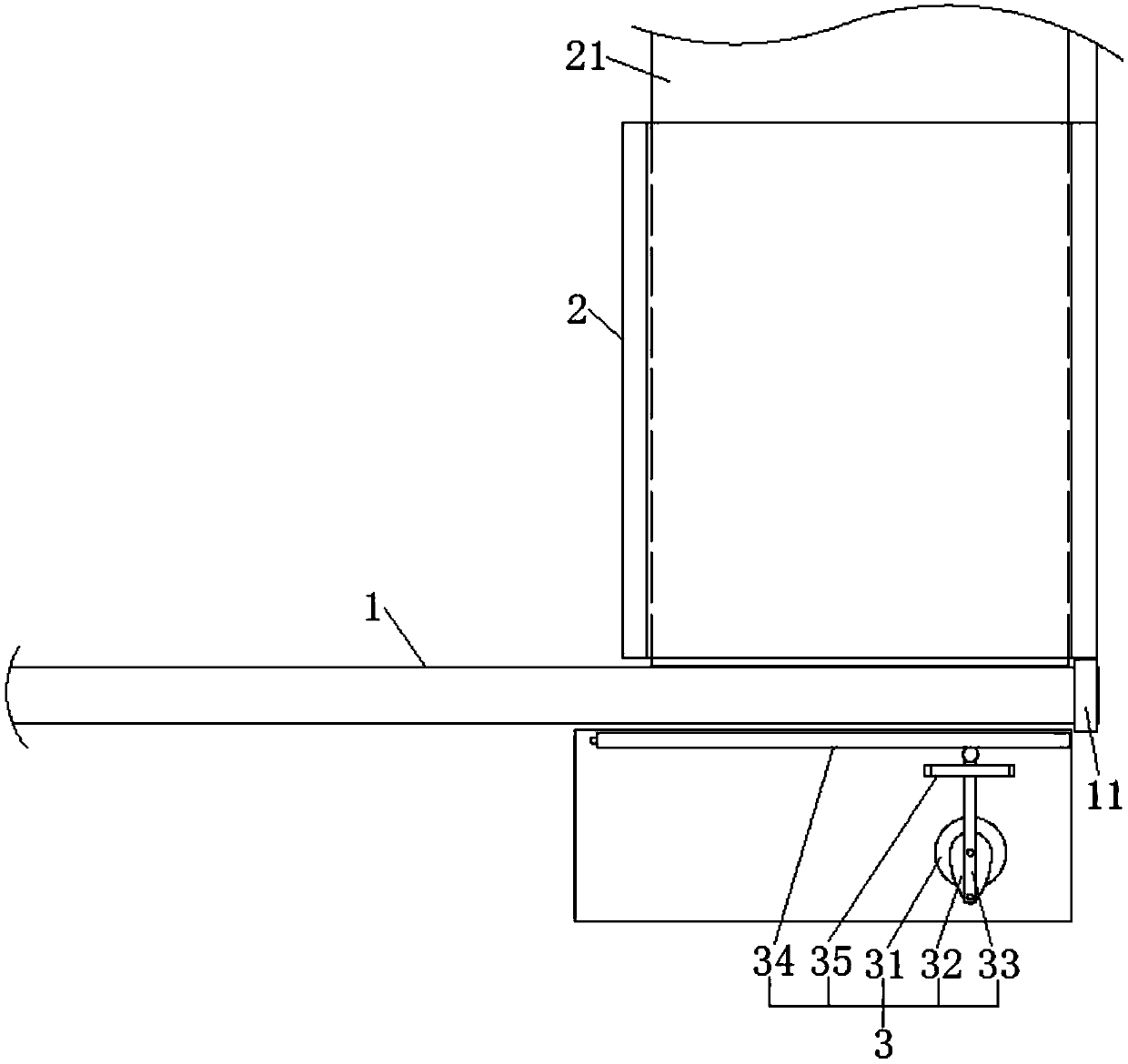

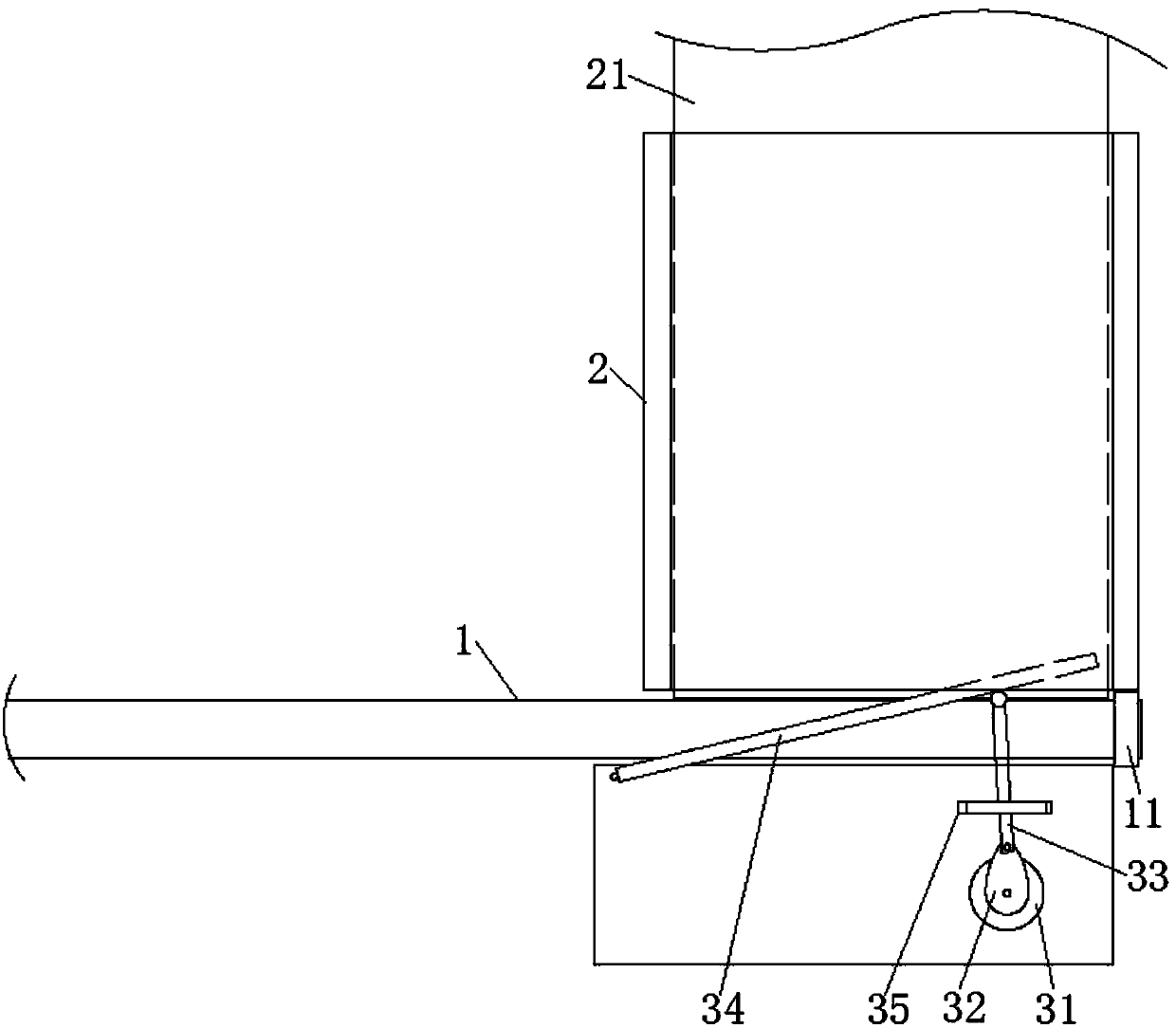

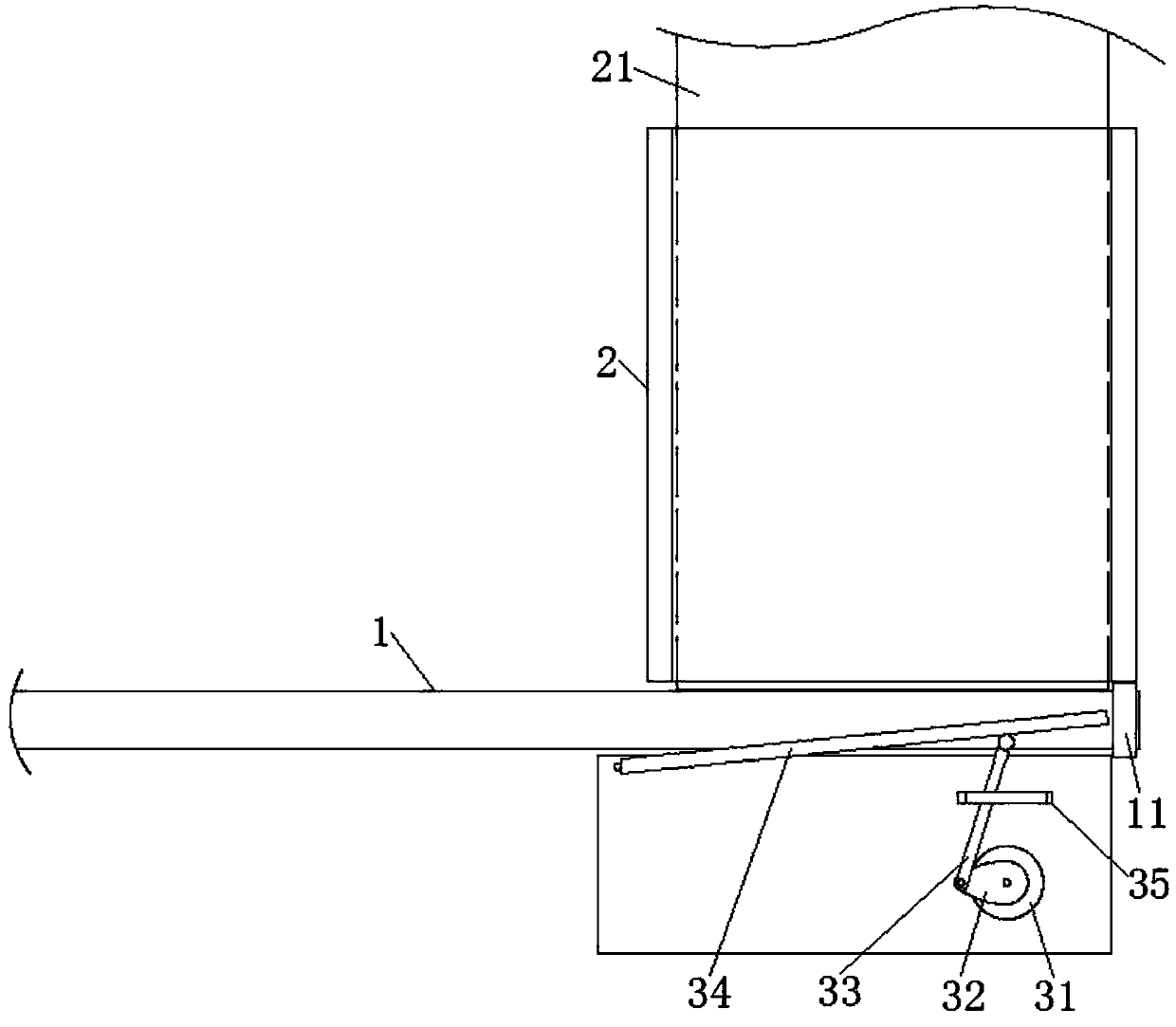

[0042] Example: such as Figures 1 to 4 As shown, the milk-containing beverage disinfection production line of this embodiment includes a first conveying device 1, a disinfection box 2 and a pushing mechanism 3;

[0043] The above-mentioned first conveying device 1 is arranged horizontally, and a material limiting baffle 11 is provided on the conveying surface of the conveying rear end;

[0044] The above-mentioned disinfection box 2 is a strip-shaped box body with two ends open, and a heating unit 22 for heating up the inside of the disinfection box 2 is provided in it;

[0045] The above-mentioned disinfection box 2 is vertically arranged on one side of the transmission rear end of the above-mentioned first transmission device 1;

[0046] In the above-mentioned disinfection box 2, a second delivery device 21 is horizontally arranged from one end to the other end. The transmission front end of the above-mentioned second delivery device 21 is close to the above-mentioned firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com