All-quartz crystal oscillator with improved package structure and preparation method thereof

A technology of quartz crystal and packaging structure, applied in electrical components, impedance networks, etc., can solve problems such as affecting the vacuum degree of products, and achieve the effects of improving versatility, improving vacuum degree, and preventing parasitic capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

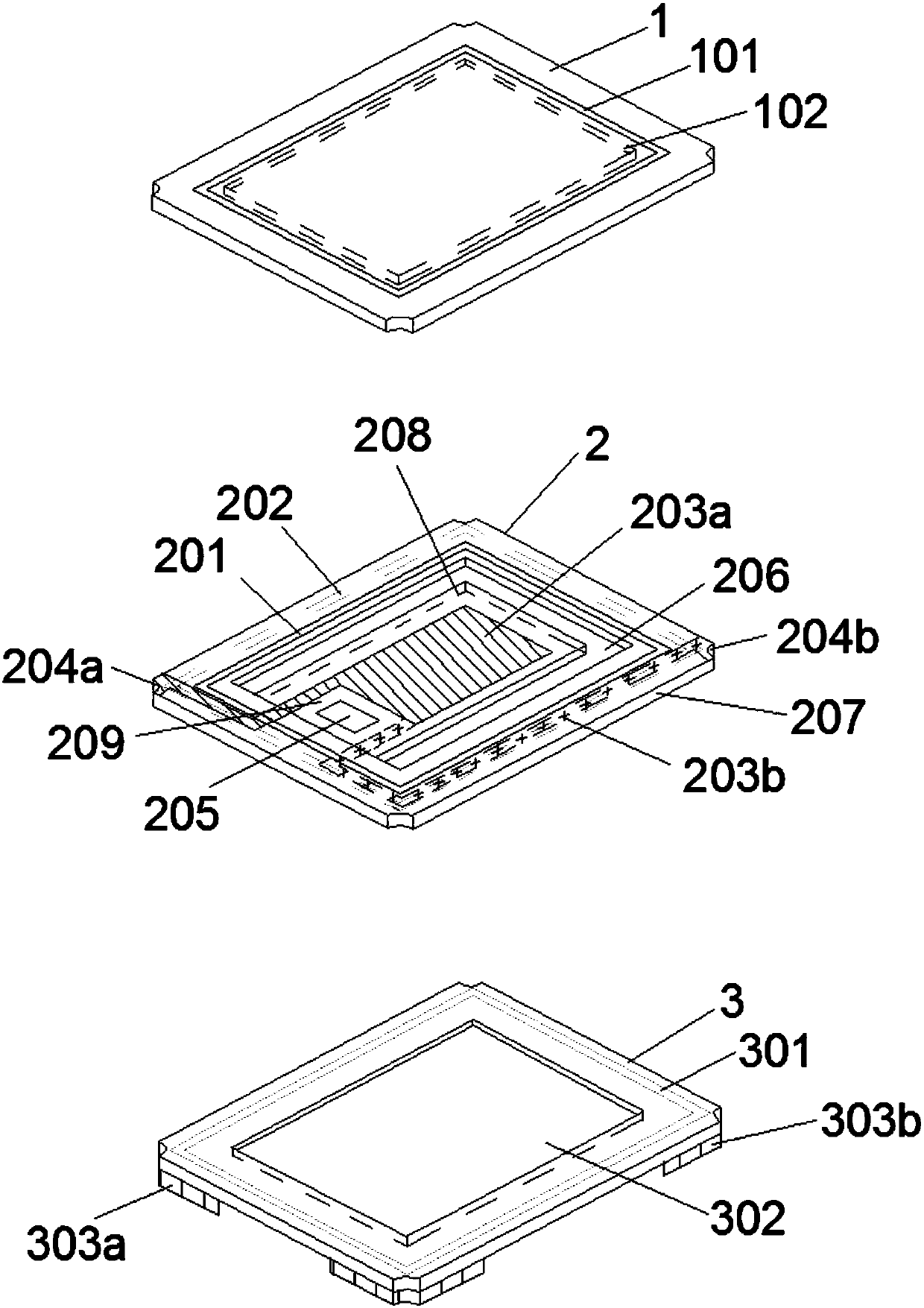

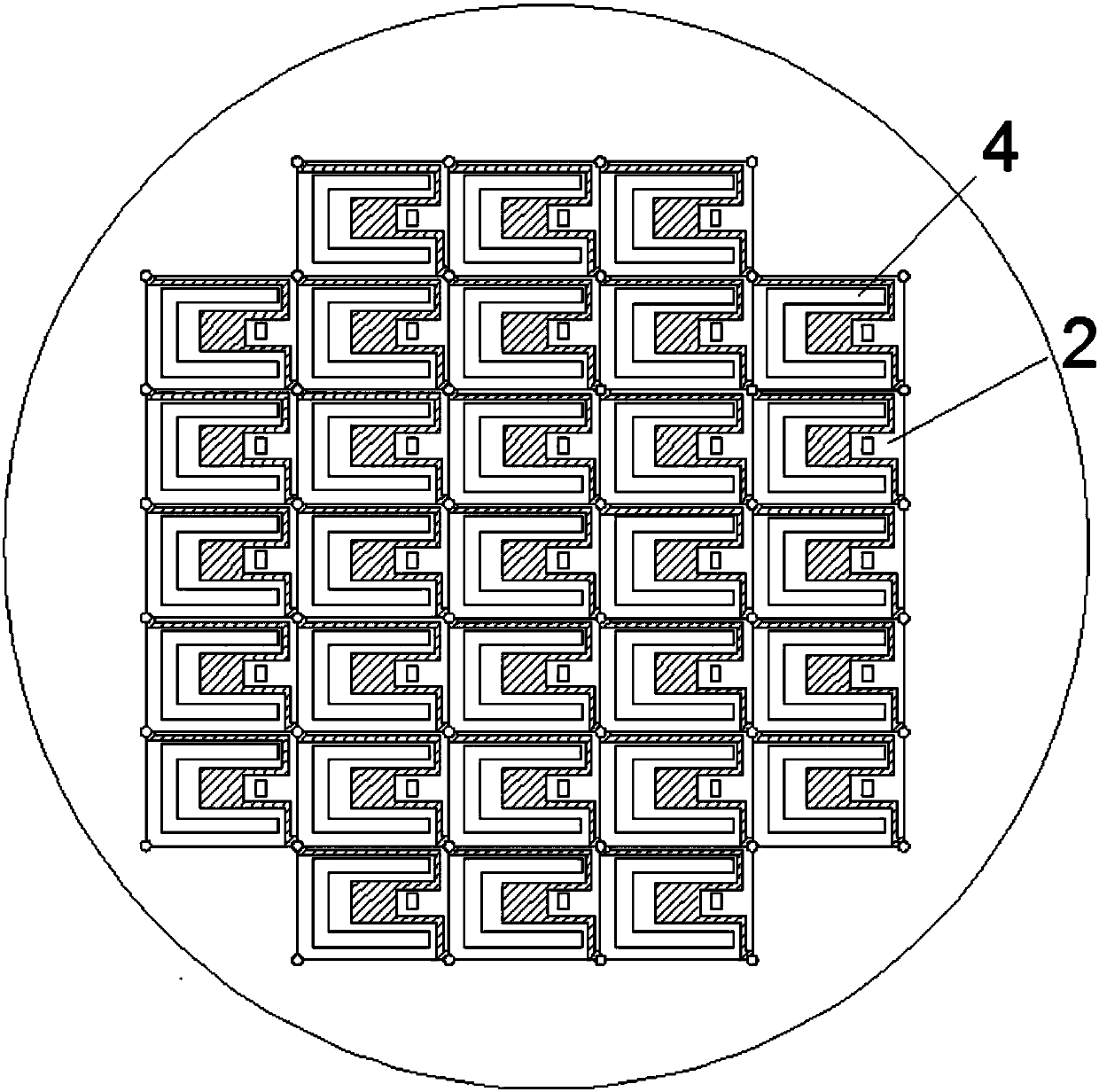

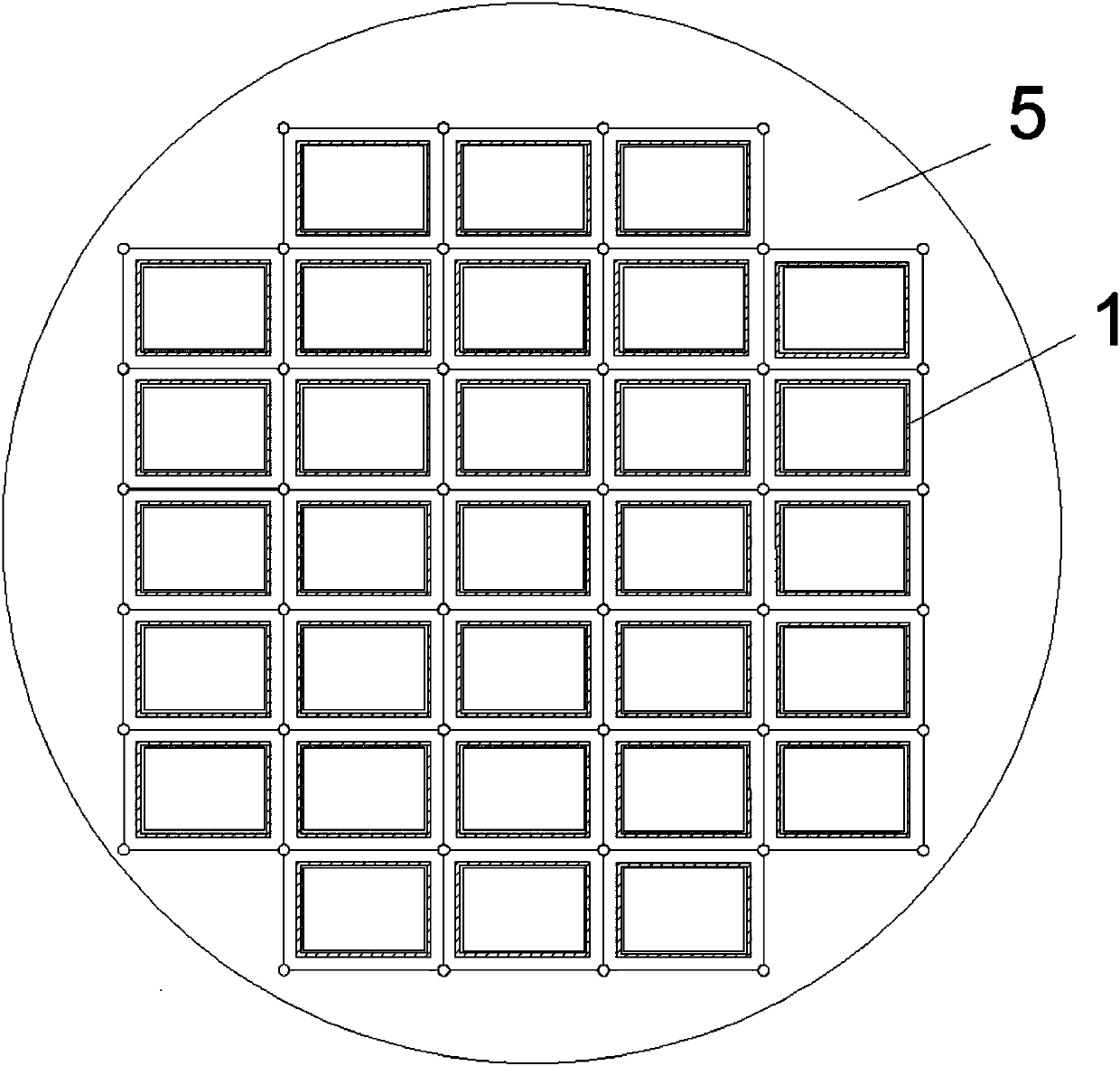

[0041] An all-quartz crystal resonator with an improved packaging structure, comprising a quartz wafer 2, a packaging cover 1 and a packaging base 3, the quartz wafer 2 includes a protective frame 207, and the upper surface of the protective frame 207 is provided with a packaging metal layer A201 The encapsulation metal layer A201 is provided with an encapsulation metal layer B202 outside the projection of the lower surface of the protective frame 207, and the encapsulation cover 1 is provided with an encapsulation metal layer C101 in the area facing the encapsulation metal layer A201, and the encapsulation base An encapsulation metal layer D301 is provided on the seat 3 facing the encapsulation metal layer B202. After encapsulation, the encapsulation metal layers on the upper and lower surfaces of the quartz wafer are staggered from each other, and no capacitance structure is formed, thus avoiding the generation of parasitic capacitance.

[0042]The quartz wafer 2 also include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com