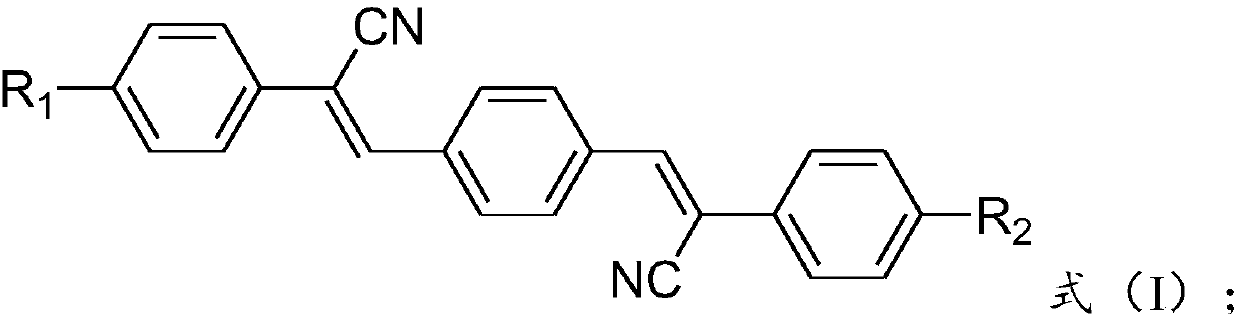

Pressure-sensitive compound, pressure-sensitive material, preparation method thereof and pressure-sensitive film

A compound and pressure-sensitive film technology, which can be used in the measurement and coating of materials by measuring the changing force of their optical properties when they are stressed. It can solve the problems of harsh processing conditions, difficult to meet market demands, and narrow operating temperature range , to achieve the effect of low processing cost, conducive to large-scale production in the market, and a wide range of usable temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] The present invention also provides a method for preparing the pressure-sensitive material described in the above technical solution, including:

[0068] The pressure-sensitive compound, modifying agent, antioxidant and heat stabilizer are mixed at 25-80°C to obtain the pressure-sensitive material.

[0069] Wherein, the pressure-sensitive compound is consistent with that described in the above technical solution, and will not be repeated here.

[0070] The present invention has no special limitation on the mixing order of the raw materials. In some embodiments, all the raw materials can be mixed together; Stabilizer mix. The present invention has no special limitation on the mixing method and equipment, as long as the raw materials can be mixed evenly, for example, a high-speed stirrer well known to those skilled in the art can be used for mixing.

[0071] In the present invention, the mixing temperature is preferably 25-80° C.; the mixing time is preferably 3-6 minut...

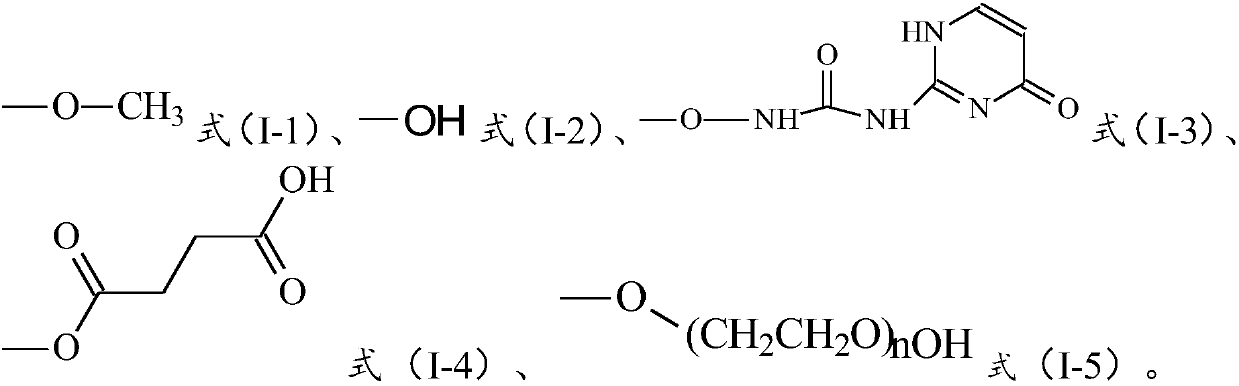

Embodiment 1

[0085] 100g formula (I) pressure sensitive compound (R 1 For formula I-2, R 2 I-3), 1g of dimethylsiloxane, 0.1g of 2,2'-methylenebis-(4-methyl-6-tert-butylphenol) and 1g of dibutyltin dilaurate are put into the mixing equipment in turn , mixed at 25° C. for 0.5 min, then at 40° C. for 1 min, and finally at 50° C. for 1 min. After mixing evenly, take it out to obtain a pressure-sensitive material.

[0086] The pressure-sensitive material is mixed with the binder to obtain a coated pressure-sensitive material, which is then coated on the surface of the substrate film at a coating speed of 3 min / m, and a pressure-sensitive film is obtained after coating.

Embodiment 2

[0088] 100g formula (I) pressure sensitive compound (R 1 For formula I-2, R 2 For I-4), 20g gamma-aminopropyltriethoxysilane, 5g2, 4-two (n-octyl thiomethylene)-6-methylphenol and 5g lead stearate drop into mixing equipment successively, in Mix at 50°C for 1 min, then at 55°C for 1 min, and finally at 60°C for 1 min, mix well and take out to obtain a pressure-sensitive material.

[0089] The pressure-sensitive material is mixed with the binder to obtain a coated pressure-sensitive material, which is then coated on the surface of the substrate film at a coating speed of 3 min / m, and a pressure-sensitive film is obtained after coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com