A sensor installation mechanism in a bridge health monitoring system

A bridge health monitoring and installation mechanism technology, which is applied in the direction of measuring devices, measuring instrument components, instruments, etc., can solve problems such as vibration data errors, and achieve the effects of reducing data errors, good close contact, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

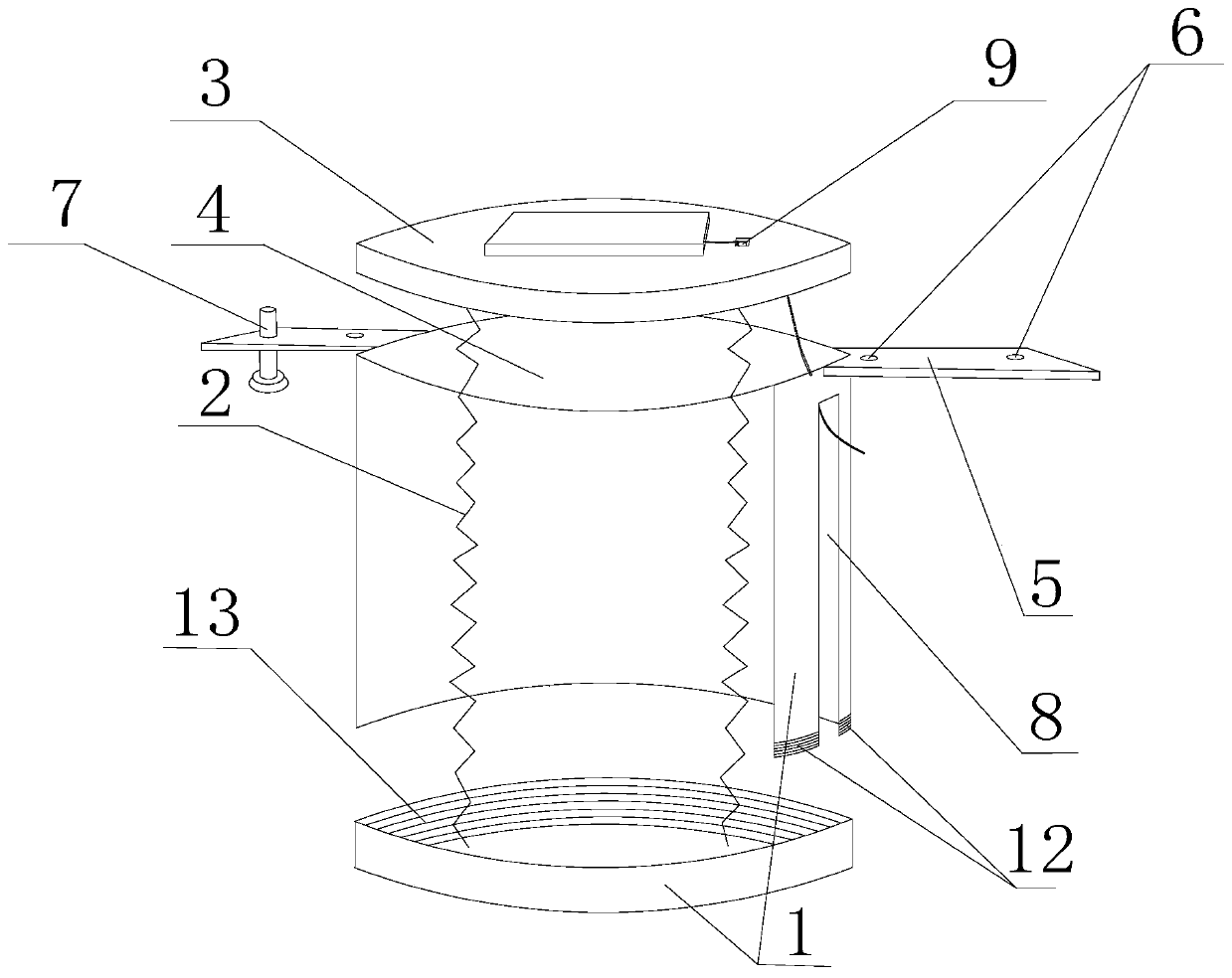

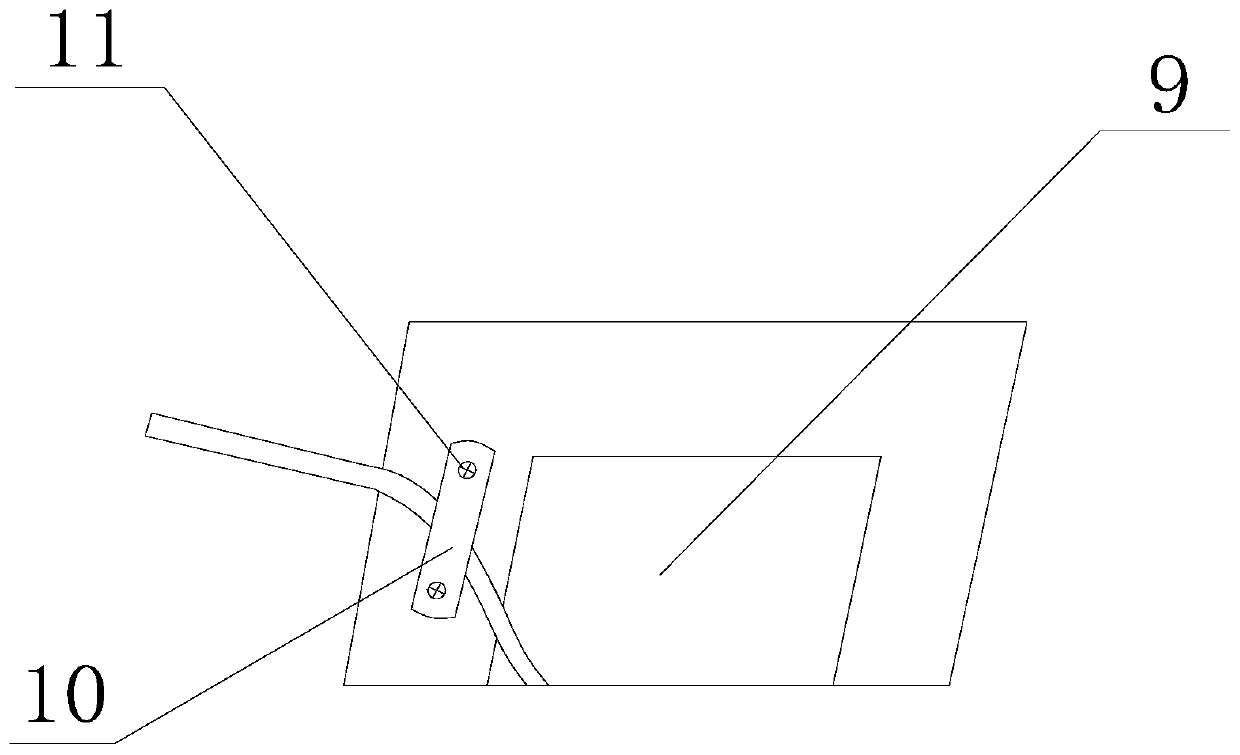

[0026] like Figure 1-2As shown, a sensor installation mechanism in a bridge health monitoring system includes a housing 1, a spring 2, and a support plate 3. An opening 4 is arranged above the housing 1, and a plurality of hanging ears 5 are arranged on the housing 1. The hanging ears 5 Symmetrical with the hanging lug 5 through the central axis of the shell 1, the hanging lug 5 is perpendicular to the side of the shell 1, and at least one threaded hole 6 is provided on the hanging lug 5, and the shell 1 is connected to the bridge deck through a screw 7 matching the threaded hole 6. The shell 1 The side is provided with a wiring port 8, and the lower end opening of the wiring port 8 is in contact with the bottom surface of the shell 1. The shell 1 is a detachable bottom surface. The bottom end of the side of the shell 1 is provided with an external thread 12. 12 with matching internal thread 13 . One end of the support plate 3 close to the wiring opening 8 is provided with a...

Embodiment 2

[0028] On the basis of Embodiment 1, when the vibration sensor itself is damaged, the bottom surface of the entire casing 1 together with the spring 2 and the support plate 3 can be taken out from the inside of the casing 1 by removing the bottom surface of the casing 1, and the connecting cable passes through the wiring port 8 Slide down directly from the side of the shell 1, replace the new vibration sensor, and then make the vibration sensor contact with the bridge deck through the inside of the shell 1, and then compress the spring 2 to connect the bottom surface of the shell 1 with the side of the shell 1. The time for replacing the vibration sensor is shortened, the operation is convenient and fast, the labor cost is saved, and the vibration sensor can monitor the bridge deck to the greatest extent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com