Grain drying machine

A grain and barn technology, applied in the field of grain drying machines, can solve the problems of time cost, high labor cost, loss of market competitiveness of rice, etc., and achieve the effect of good effect, guaranteed adequacy, and uniform grain distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

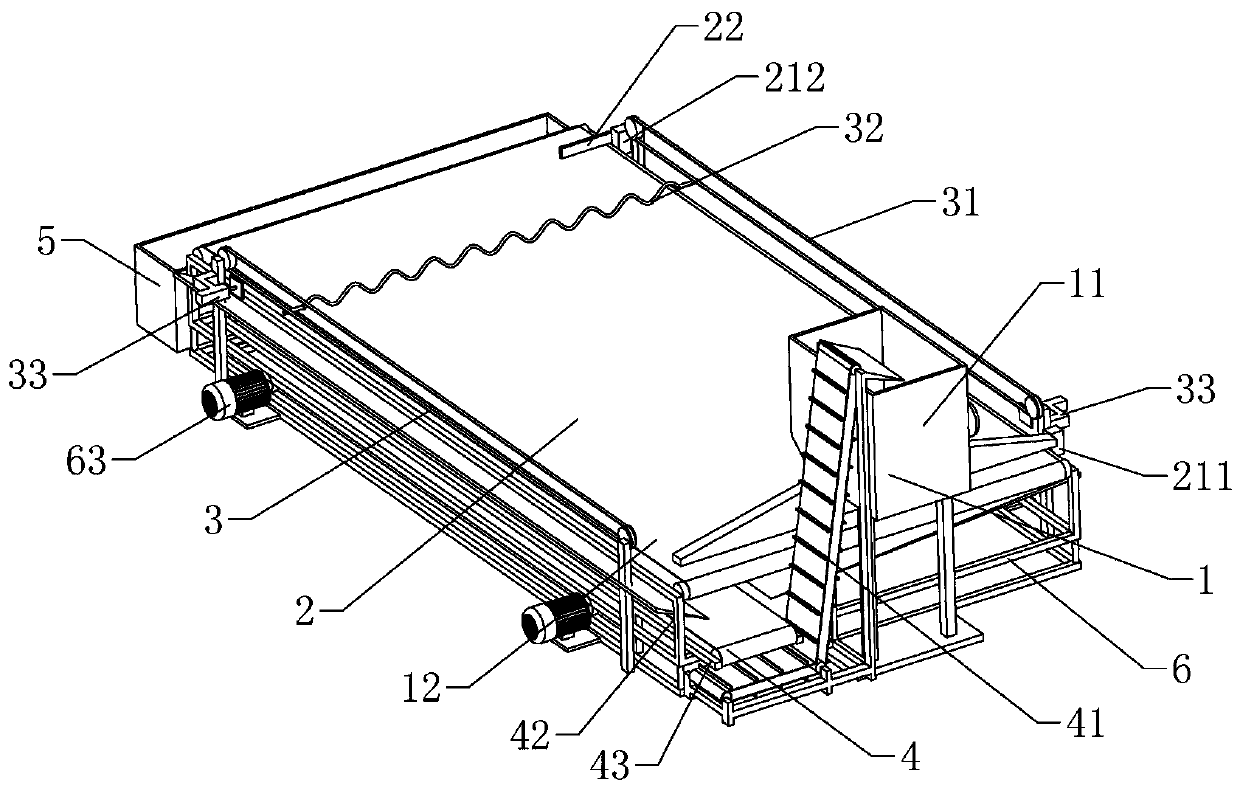

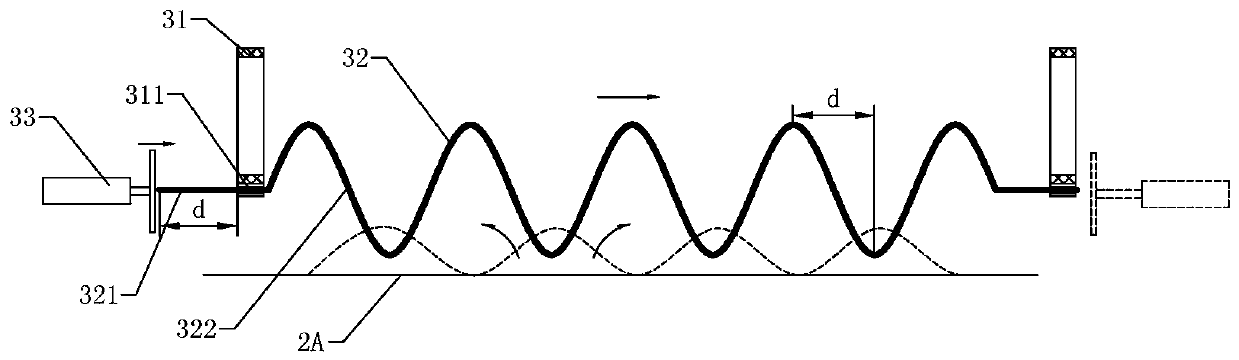

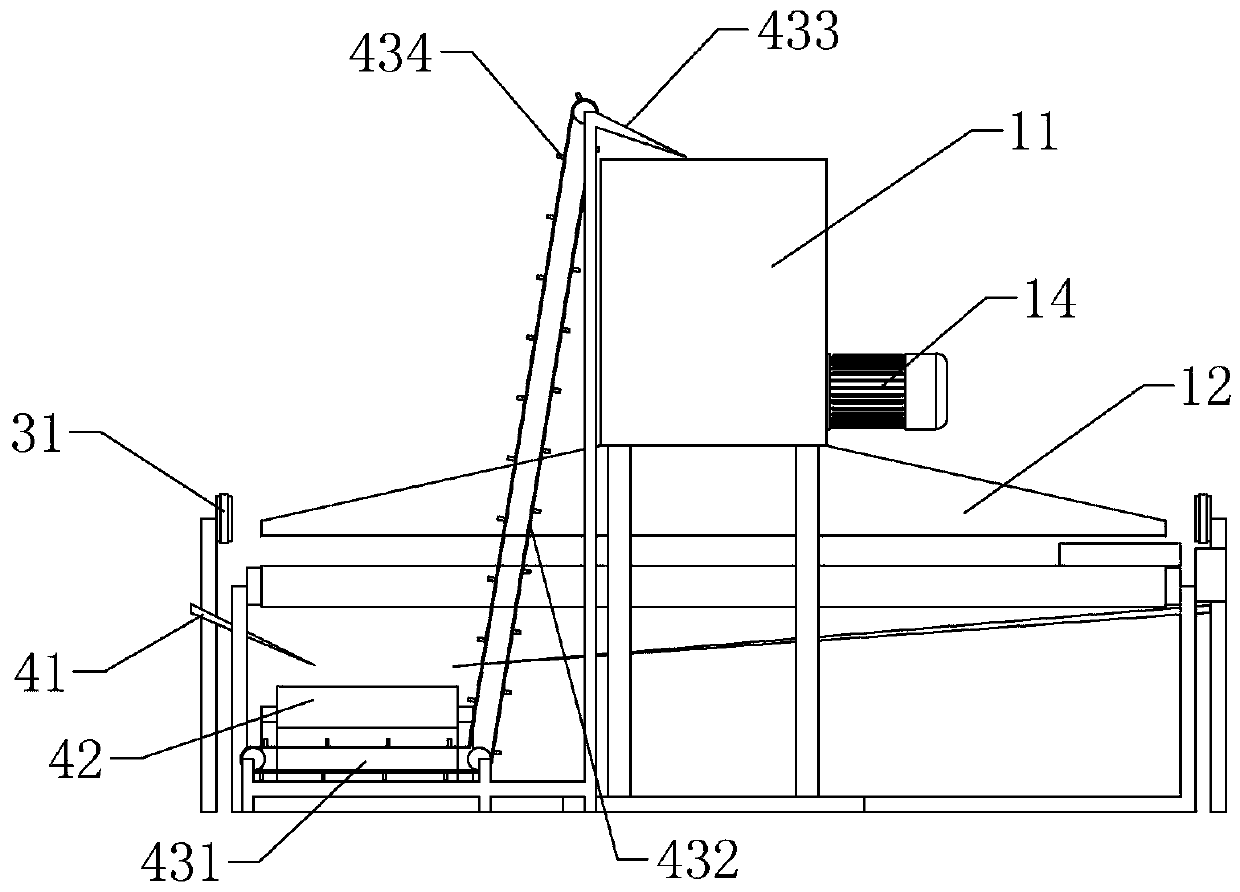

[0030] according to Figure 1 to Figure 7 As shown, a grain drying machine includes: a lower barn 1, a grain drying belt 2, a grain turning mechanism 3, a falling grain recovery mechanism 4, and a grain harvesting bin 5. The lower barn 1 is used to scatter the grain on the grain drying belt 2, The grain turning mechanism 3 is used to automatically turn over the grains on the grain drying belt 2;

[0031] The lower barn 1 is arranged on one end of the grain drying belt 2, the upper part is a barn storage 11, and the lower part is a grain-dividing mouth 12 gradually widening from top to bottom, and several evacuation grooves 13 arranged obliquely are arranged in the grain-dividing mouth 12. Door switch 14 is provided between valley mouth 12, and the top opening size of all evacuation grooves 13 is identical, and the bottom opening size of all evacuation grooves 13 is also identical, thereby guarantees the evenness of scattering grain.

[0032] according to figure 1 , image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com