Coal seam drilling exploding extracting and injecting integrated anti-outburst method

A coal seam, drilling and blasting technology, applied in the direction of mining fluid, earthwork drilling, gas discharge, etc., can solve the problems of uncontrollable damage range and direction of high-pressure water, complicated procedures and processes, which need to be investigated and perfected, so as to maintain mine safety Efficient production, enhanced gas drainage effect, enhanced plasticity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

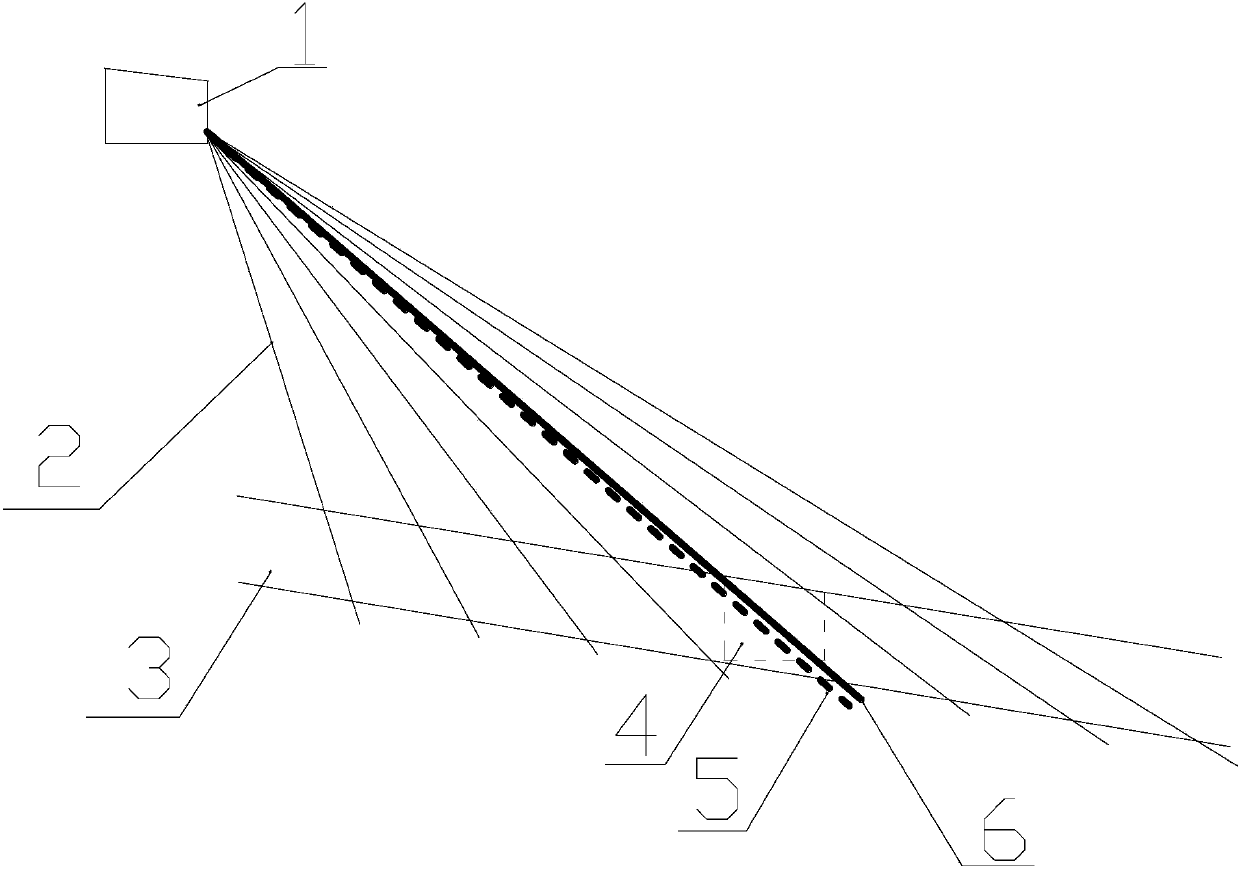

[0027] Example 1: Coal seam drilling, blasting, pumping and injection integrated outburst prevention method to cover coal roadway excavation

[0028] The coal seam drilling, blasting, pumping and injection integrated outburst prevention method of the present invention is used for strip gas control in coal roadways and for protecting coal roadway excavation. When excavating the coal roadway 4 in the coal seam 3, a special gas control roadway 1 can be arranged in the coal seam roof rock layer where the coal seam 4 is located. The spatial position of the gas control roadway 1 is determined according to the geological conditions and the lithology of the coal seam 3 roof. The vertical distance from the coal seam 3 where the coal roadway 4 is located is 10-30m. When the lithology hardness of the roof of the coal seam 3 is relatively high and relatively complete, take a small value; otherwise, take a large value. The distance can be increased appropriately.

[0029] From the special...

Embodiment 2

[0031] Example 2: Coal seam drilling, blasting, pumping and injection integrated outburst prevention method to cover coal mining face mining

[0032] The coal seam drilling, blasting, pumping and injection integrated outburst prevention method of the present invention can also be used to control section coal seam gas and to protect the recovery of coal seam working faces. Before the coal seam is recovered, a special roadway 1 for gas control is constructed on the roof or floor of the coal seam, and the integrated drilling, blasting and pumping injection technology is implemented according to the sequence in the first embodiment. The same part is omitted, the difference lies in the difference in the scope of drilling control, and the scope of drilling layout is required to meet the requirements of the national "Coal Mine Safety Regulations", "Regulations on Prevention and Control of Coal and Gas Outburst" and local regulations.

[0033] The spatial position of the special roadw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com