Downhole speed-increase and effect-increase tool under effect of dual pressure cavities and speed-increasing method

A dual-pressure, pressure chamber technology, applied in the field of hard formations with poor drillability and high abrasiveness, can solve the problems of reduced maximum depth capability, high friction, and affecting oil well production, so as to reduce friction and improve Drilling precision and small radial vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

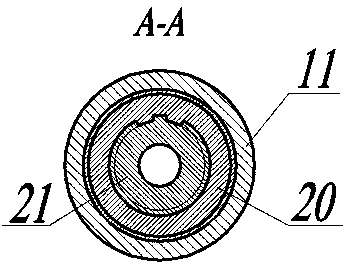

[0011] Such as figure 1 , figure 2 As shown, the downhole speed-improving tool with dual pressure chambers mainly includes upper casing, inlet screw, lock nut, upper spring support, No. 1 spring, threaded shaft of valve assembly, No. 2 spring, lower spring support, and main gasket , middle shell, valve port, impact nut, piston, No. 3 spring upper support, No. 3 spring, No. 3 spring lower support, gasket, lower shell and impact assembly shaft, and its structural features are: the upper shell and the middle shell cooperate , the inlet screw is installed on the inner wall at the entrance of the upper casing, the upper spring support and the lower spring support are installed in the annular space between the upper casing and the threaded shaft of the valve assembly, and the No. 1 spring is installed between the upper spring support and the lower spring support, The No. 2 spring is installed on the lower support of the spring and is not in contact with the upper support of the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com