High-strength steel column-common steel beam steel brace-low-yield-point steel coupling beam restorable structure

A low-yield point steel, reset structure technology, applied in building components, building structures, building types, etc., can solve the problem that new steel does not give clear regulations or guidance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

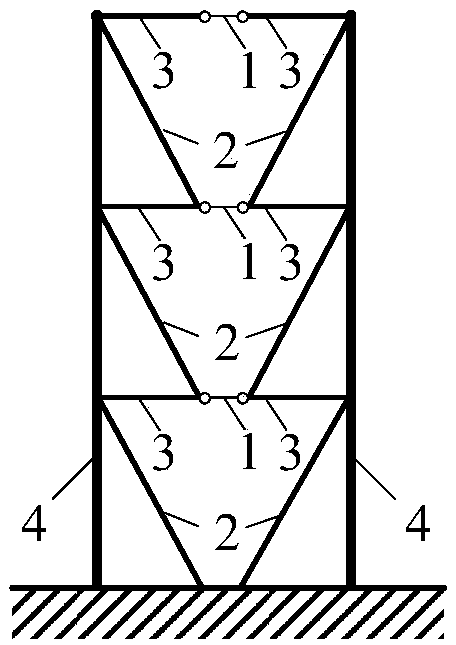

[0043] like figure 1 As shown, a high-strength steel column-common steel beam steel support-low-yield point steel coupling beam can be reset, including low-yield point steel coupling beam 1, common steel support 2, common steel frame beam 3 and high-strength steel frame column 4 , one end of the low yield point steel connecting beam 1 in each layer is connected with the ordinary steel frame beam 3, and the other end is connected with another ordinary steel frame beam 3; the upper end of the ordinary steel support 2 is connected with the The ends of the common steel frame beam 3 are connected, and the lower end is connected with the connection node of the high-strength steel frame column 4 and another common steel frame beam 3; one end of the common steel frame beam 3 is connected with the low yield point steel The connecting beam 1 is connected, and the other end is connected with the high-strength steel frame column 4; when an earthquake occurs, the low-yield point steel conn...

Embodiment 2

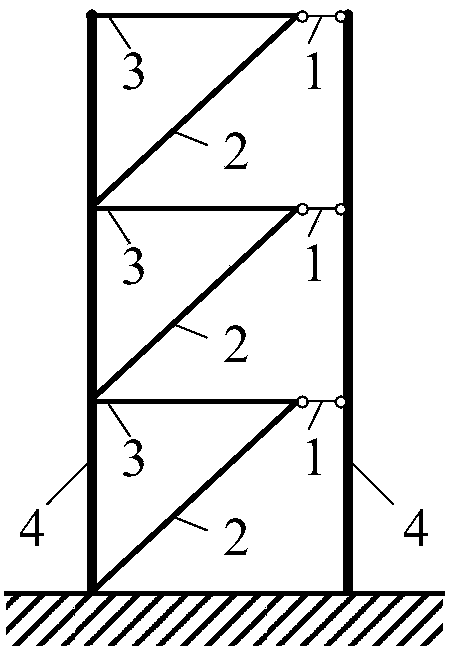

[0071] like figure 2 As shown, the difference between this embodiment and Embodiment 1 is:

[0072] A high-strength steel column-common steel girder steel support-low yield point steel connecting beam repositionable structure, including low yield point steel connecting beam 1, common steel support 2, common steel frame beam 3 and high-strength steel frame column 4, the One end of the low yield point steel connecting beam 1 is connected to the ordinary steel frame beam 3, and the other end is connected to another ordinary steel frame beam 3; the lower end of the ordinary steel support 2 is connected to the end of the ordinary steel frame beam 3 The upper end is connected with the connection node of the high-strength steel frame column 4 and another ordinary steel frame beam 3; one end of the ordinary steel frame beam 3 is connected with the low yield point steel connecting beam 1, and the other One end is connected to the high-strength steel frame column 4; when an earthquake...

Embodiment 3

[0074] like image 3 As shown, the difference between this embodiment and Embodiment 1 is:

[0075] A high-strength steel column-common steel girder steel support-low yield point steel connecting beam repositionable structure, including low yield point steel connecting beam 1, common steel support 2, common steel frame beam 3 and high-strength steel frame column 4, the One end of the low yield point steel connecting beam 1 is connected to the ordinary steel frame beam 3, and the other end is connected to the high-strength steel frame column 4; the upper end of the ordinary steel support 2 is connected to the end of the ordinary steel frame beam 3 , the lower end is connected with the connection node of the high-strength steel frame column 4 and another ordinary steel frame beam 3; one end of the ordinary steel frame beam 3 is connected with the low yield point steel connecting beam 1, and the other end is connected with the The high-strength steel frame columns 4 are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com