Pitching type bearing frame for high-speed beam transport vehicle

A technology of load-carrying frame and beam-carrying vehicle, which is applied in the direction of freight vehicles, motor vehicles, and load fixing, and can solve the problems of passability, ease of use, poor durability performance, poor tire adhesion to the road surface, and beam-carrying turntable. Concrete beams and other problems, to achieve good anti-overturning stability, low manufacturing cost, and improve transportation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment the present invention will be further described, but the present invention is not limited to these examples, under the premise of departing from the gist of the present invention, any improvement made falls within the protection scope of the present invention.

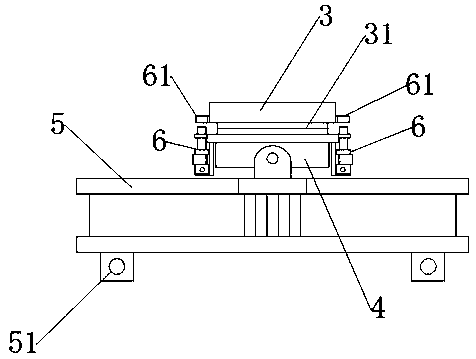

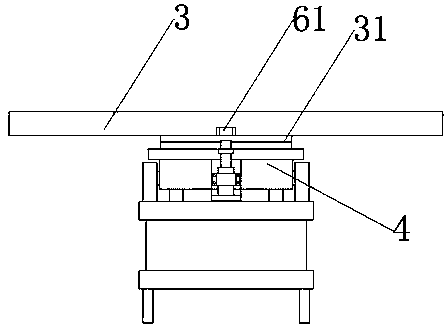

[0016] As shown in the figure, a high-speed beam transport vehicle auxiliary tilting carrier frame according to the present invention includes a vehicle frame 5, a pitching frame 4 and a load-carrying turntable frame 3 arranged on the upper part of the pitching frame, and the bottom of the pitching frame 4 It is fixed on the vehicle frame 5 by hinge parts, and it swings freely back and forth. The described carrying turntable frame includes a rectangular carrying frame and a rotating disk 31, and the described rectangular carrying frame is fixed above the pitch frame by the rotating disk 31; The pitching frame is a square structure, and any two sides parallel to each other are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com