Maintenance based heat conduction medium assisted module of mould temperature controller

A technology of heat conduction medium and auxiliary module, which is applied in the field of mold temperature controller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

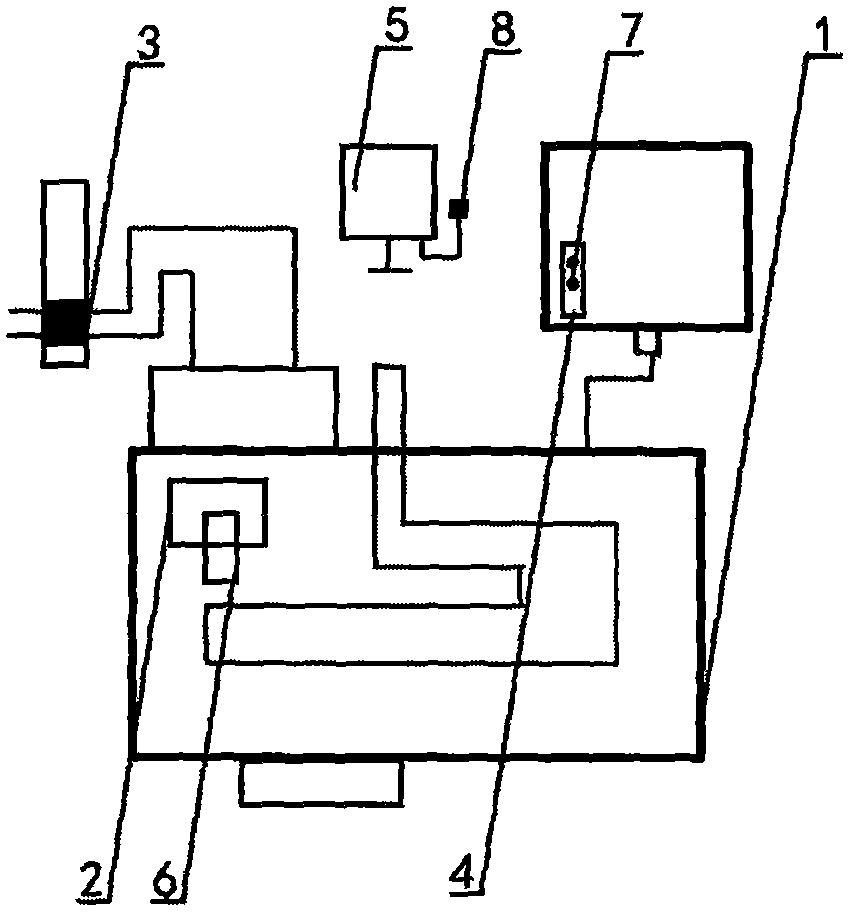

[0012] Embodiment: as shown in the accompanying drawing. A mold temperature machine is based on an auxiliary module for maintenance of heat transfer media, including a body (1), on which a media selection module (2), a filter module (3), a temperature sensing module (4), and a management module (5 ), during operation, the medium selection module (2) selects the medium liquid used in the operation, the filter module (3) filters the passing medium liquid, the temperature sensing module (4) senses the temperature value in the fuselage, and the management module (5) processes the comprehensive information .

[0013] A mold temperature machine is based on an auxiliary module for maintaining a heat-conducting medium, and a dialogue display module (6) is provided on the medium selection module (2) to display the selected medium liquid in real time.

[0014] A mold temperature machine is based on an auxiliary module for maintaining a heat-conducting medium, and a replacement indicati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com