Lateral contraction type stirring paddle for coating reaction kettle

A technology of horizontal shrinkage of kettle and stirring paddle, which is used in mixer accessories, mixers with rotary stirring devices, chemical/physical/physical-chemical stationary reactors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

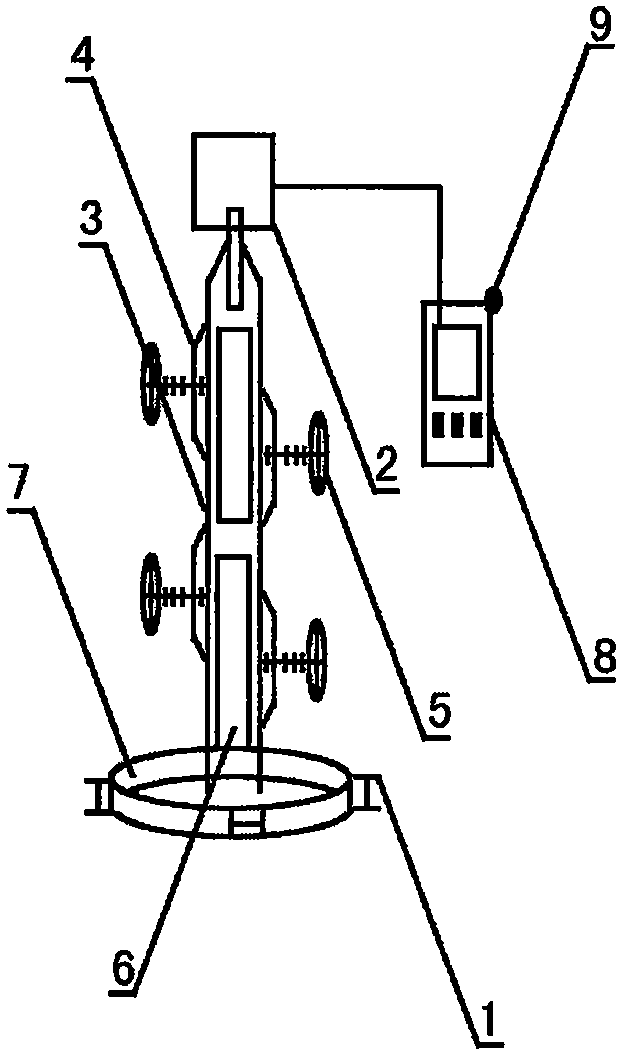

[0012] Embodiment: as shown in the accompanying drawing. A horizontally retractable stirring paddle for a paint reaction kettle, comprising a paddle frame (1), the electric device (2) on the upper part of the paddle frame (1) is located at the outer end of the paint reaction kettle, and the main slurry part includes a lifting column (3), a scraper Structure (4), retractable stirring wings (5), storage compartment (6), a rotating dispersing disc (7) is installed at the bottom, and the main control device (8) is located outside the reaction kettle, and the medium is rotated, stirred and mixed according to the reaction requirements during use. Uniform or dispersed mixing operations, when the operating status is different, the stirring blade (5) is stored in the storage compartment (6).

[0013] The utility model relates to a horizontally shrinking stirring paddle of a paint reaction kettle, which is provided with a prompting device (9) to provide different prompts for two operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com