Bridge construction equipment

A technology for construction equipment and bridges, applied in the field of bridge construction, can solve the problems of difficulty in controlling the laying height of bricks, difficult to grasp the strength of beating, and inability to compact multiple bricks, etc., and achieves simple structure, convenient operation and extended service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

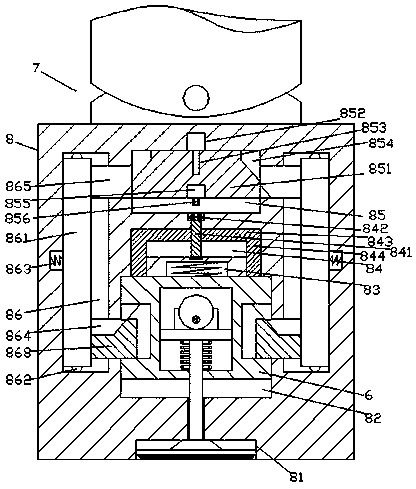

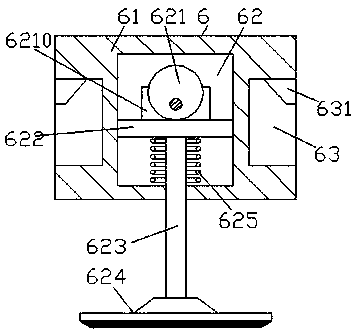

[0015] Such as Figure 1-Figure 6 As shown, a bridge construction equipment of the present invention includes an azimuth adjustment device 7 and a housing 8 installed at the bottom of the azimuth adjustment device 7, and a sunken cavity 81 is provided in the end surface of the bottom of the housing 8, and the sunken cavity The housing 8 on the upper side of the 81 is provided with a lifting groove 82, and a compacting device 6 is slidingly fitted in the lifting groove 82, and the compacting device 6 includes a lifting block 61 and is arranged on the lifting The compacting member in the lowering block 61, the left and right sides of the lifting block 61 are provided with concave cavities 63 in proportion, and the inner top wall of each of the concave cavities 63 is fixed with a first oblique block 631, so A first elastic member 83 abutting against the top end surface of the lifting block 61 is provided at the middle position in the inner top wall of the lifting groove 82, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com