Outer drum of washing machine, washing machine and control method

A washing machine and outer tub technology, applied in the field of washing machines, can solve the problems of loss of motor, affecting the life of the motor, increasing the energy consumed by the whole machine, etc., to achieve the effect of reducing maintenance costs, increasing costs, and improving lifting capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

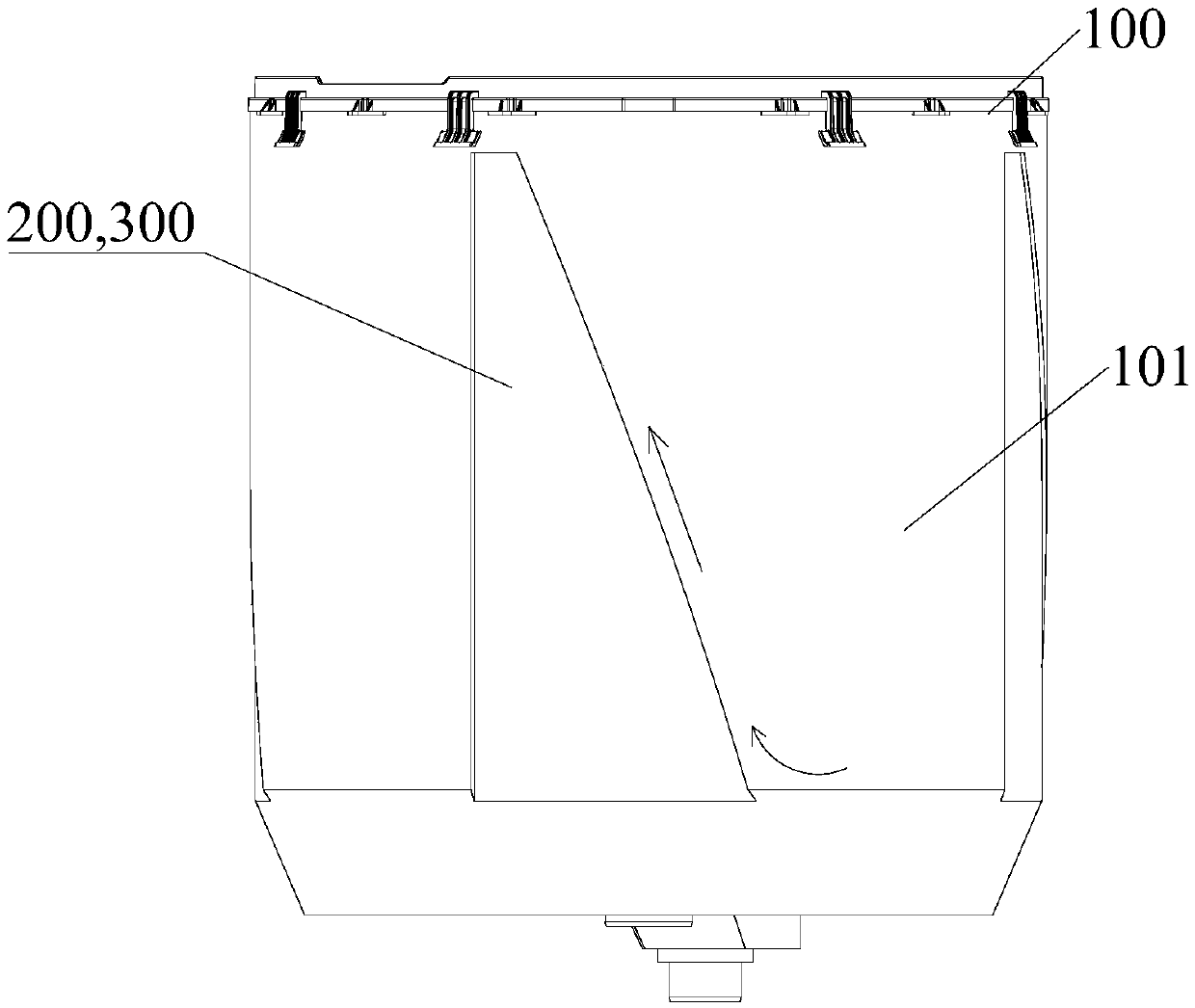

[0043] Such as Figure 1-3 As shown, the present embodiment provides an outer tub 100 of a washing machine. The inner wall of the outer tub 100 is provided with a lifting part 200 protruding inwardly relative to the inner wall of the outer tub 100 and extending upward from the lower part of the outer tub 100. The outer tub 100 The rotating water flow at the bottom climbs up to the upper part of the outer tub 100 along the lifting part 200 , and sprays into the inner tub along the cover of the outer tub 100 .

[0044] In this embodiment, a lifting portion 200 is provided on the inner wall of the outer tub 100 of the washing machine. The lifting portion 200 protrudes inwardly relative to the inner wall of the outer tub 100 and extends upward from the bottom of the outer tub 100. When the inner tub and / or the wave wheel of the washing machine rotate , driving the water flow to rotate, the rotating water flow at the bottom of the outer tub 100 can smoothly climb upward along the l...

Embodiment 2

[0073] This embodiment provides a washing machine with the outer tub of the washing machine as described in Embodiment 1. The washing machine includes an inner tub in which a pulsator is arranged, an outer tub cover is installed on the upper part of the outer tub, and the inner tub and / or the pulsator are driven to rotate The water flow climbs up to the upper part of the outer barrel along the lifting part on the inner wall of the outer barrel, and sprays into the inner barrel along the outer barrel cover.

[0074] The outer periphery of the outer tub lid is sealed and connected with the upper part of the outer tub. When washing, the motor drives the pulsator and / or the inner tub to rotate, and then drives the water flow to rotate. Under the centrifugal force generated by high-speed rotation, the water flow can rotate along the inner and outer tubs. flow, and climb upward along the lifting surface of the raised structure extending from bottom to top and inclined along the direc...

Embodiment 3

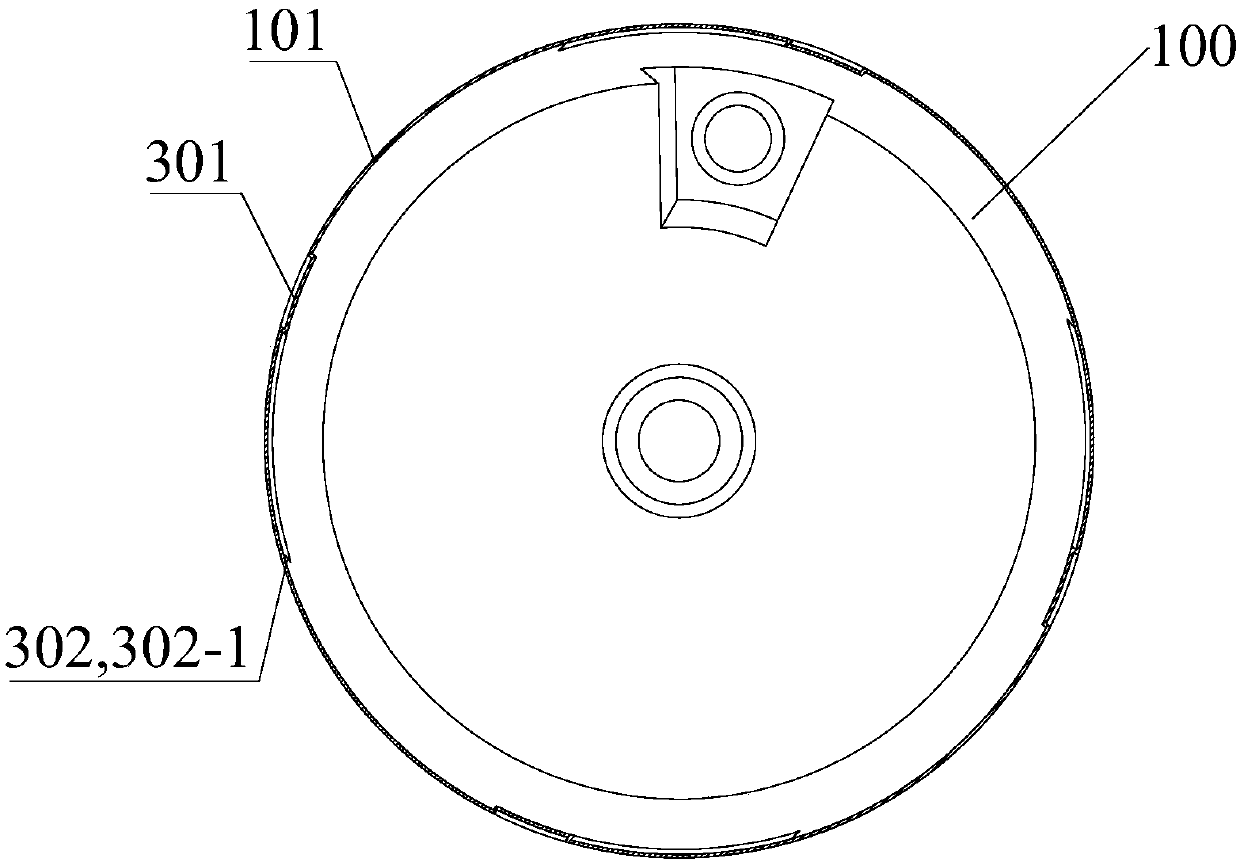

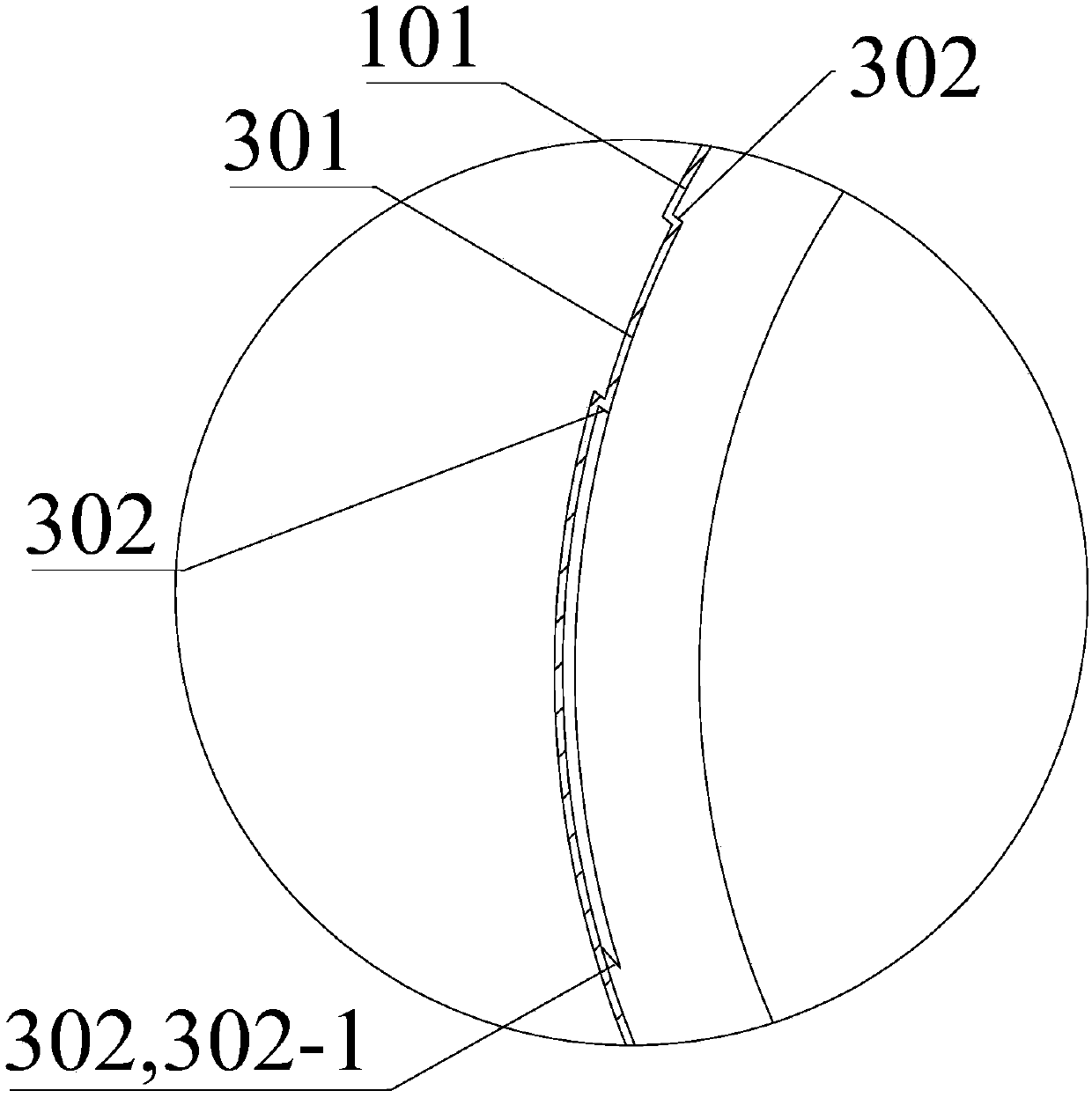

[0076] Such as Figure 4-5 As shown, this embodiment is a further limitation of Embodiment 2. A diversion structure 3 is arranged on the outer barrel cover, and the diversion structure 3 forms a diversion channel. The lifting surface of the raised structure is connected with the diversion structure correspondingly, and the water flow Climb up along the lifting surface and enter the outer barrel cover along the diversion structure. When reaching the outer barrel cover, the water flows into the diversion channel along the direction of rotation, and then sprays out from the narrowed water outlet of the diversion channel to form a dispersed spray water flow , spray on the clothes in the inner bucket.

[0077] The outer barrel cover includes a ring-shaped body, and a plurality of flow guide structures 3 arranged on the lower end surface of the outer barrel cover extend from the outer peripheral side of the body to the inner peripheral side, and are arranged in accordance with the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com