Motor-Actuable And Vertically Movable Door

A door panel and motion technology, used in windows/doors, door/window accessories, power control mechanisms, etc., can solve problems such as large installation space, and achieve the effects of less energy, less complexity, and less wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

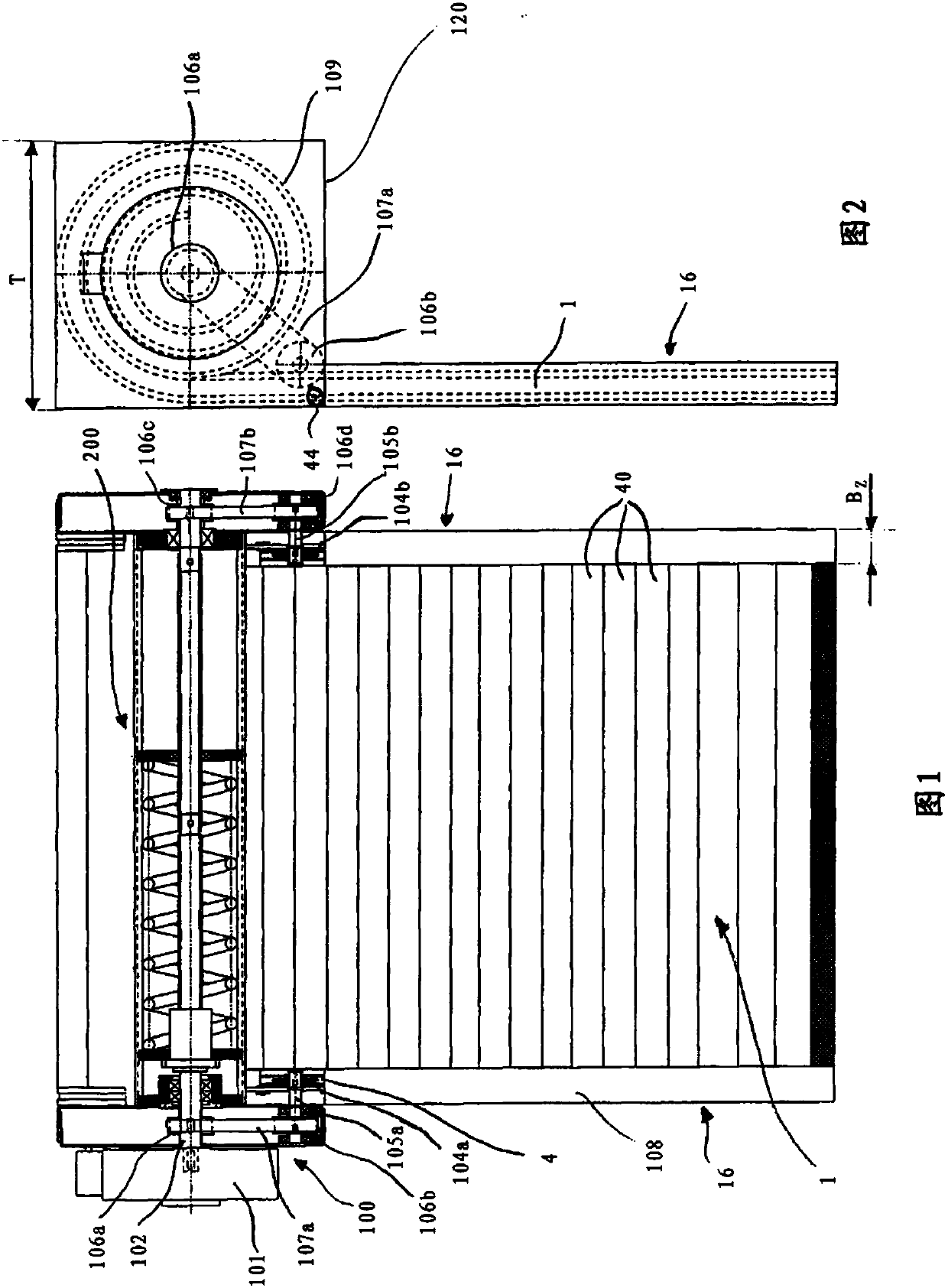

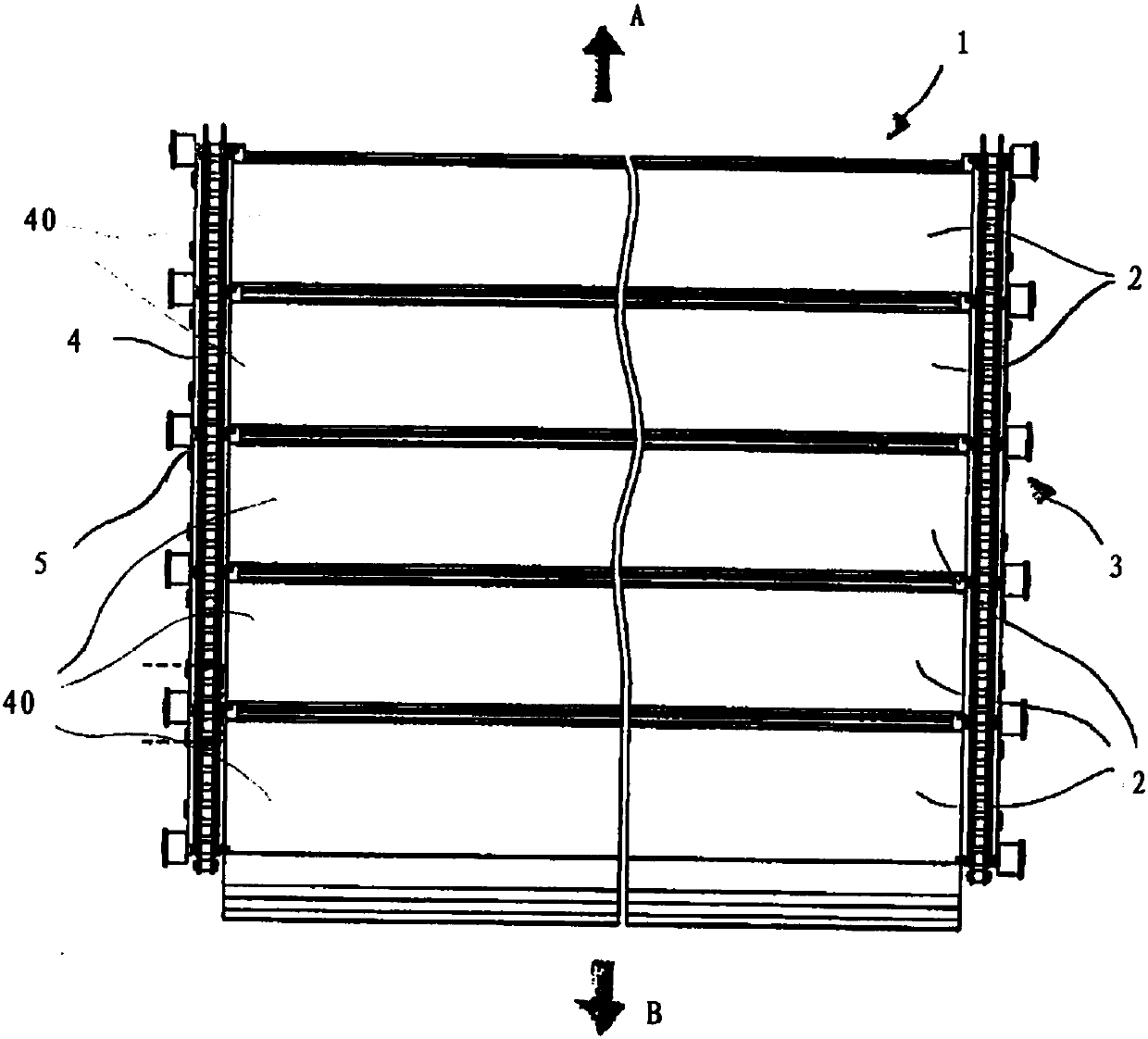

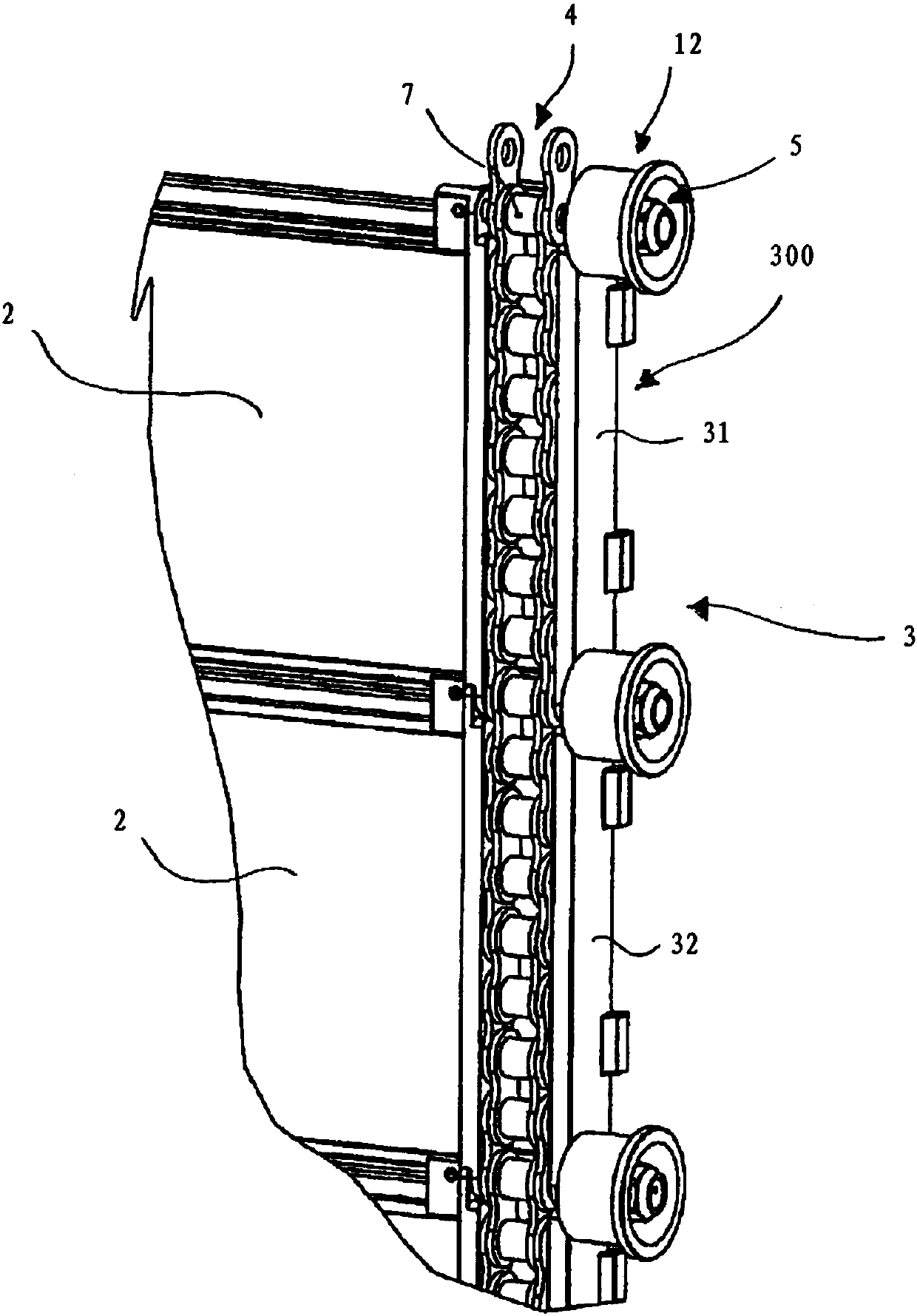

[0070] figure 1 A liftgate according to the invention is shown with a door panel 1 comprising a plurality of door panel sections 40 . Two adjacent door panel sections 40 pass through at least one hinge 3 (see Figure 4 ) are hingedly connected to each other.

[0071] The lift gate also comprises a motor drive 100 for lifting and lowering the door panel 1 and drive means in the form of a limited drive chain 4 .

[0072] The motor drive 100 also includes a drive motor 101 connected to the drive chain 4 .

[0073] The drive chain 4 is driven via a sprocket 104a serving as a drive element. The sprocket 104a is moved by an output shaft 105a, which is connected to the motor output shaft 102 via a force transmission means, currently a toothed or V-belt 107a. The belt 107a is further guided on two deflection rollers 106a, 106b. Here, by means of the size of the deflection rollers 106a, 106b, an increase or decrease ratio of the force to be transmitted can be achieved.

[0074] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com