Storage acceleration test device of lubricating grease

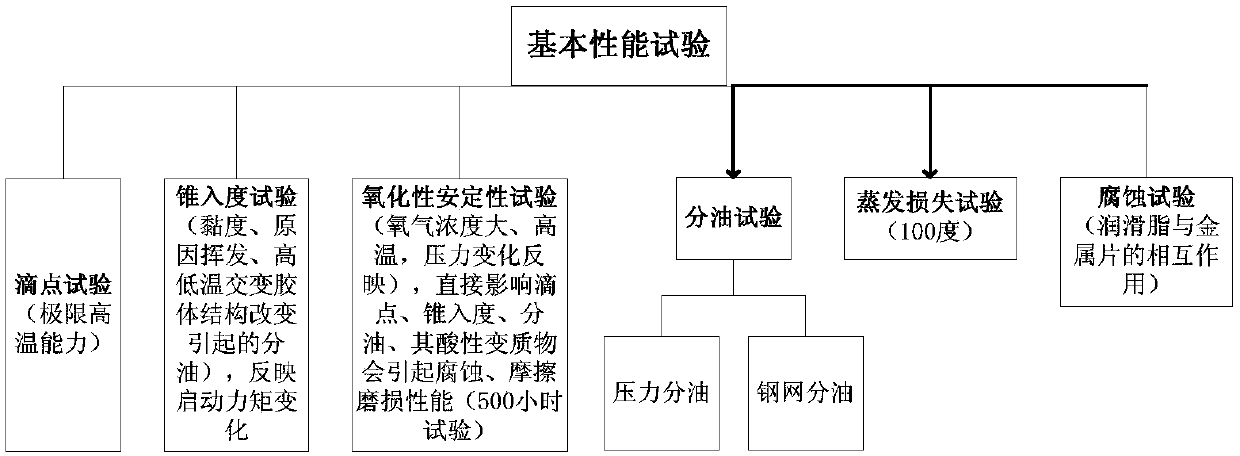

An accelerated test and lubricating grease technology, applied in measuring devices, material inspection products, instruments, etc., can solve the problems of grease storage performance analysis and the inability to evaluate the reliability of electromechanical servo systems, etc., to achieve easy grease content, easy placement, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

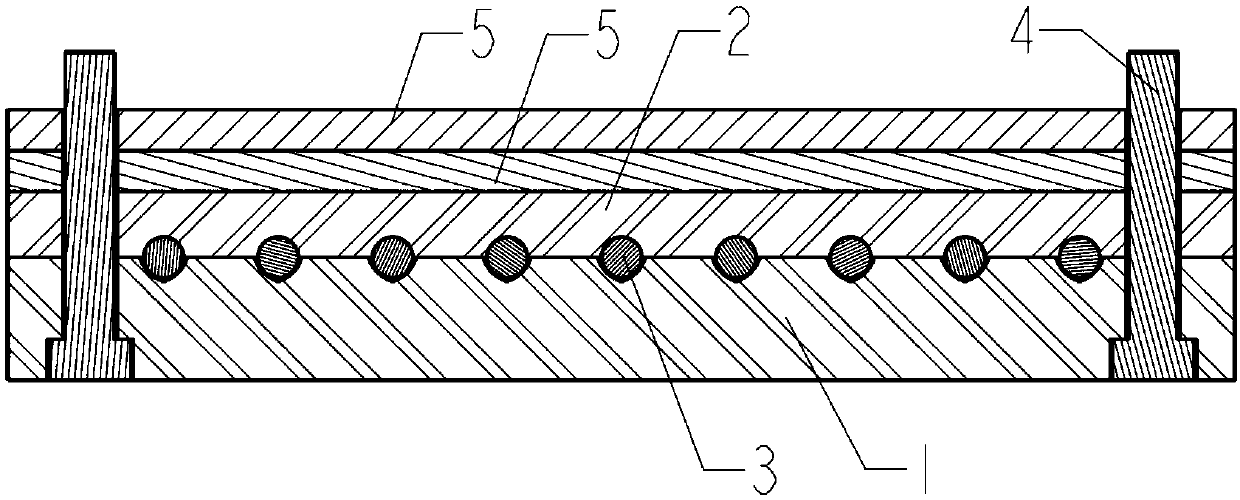

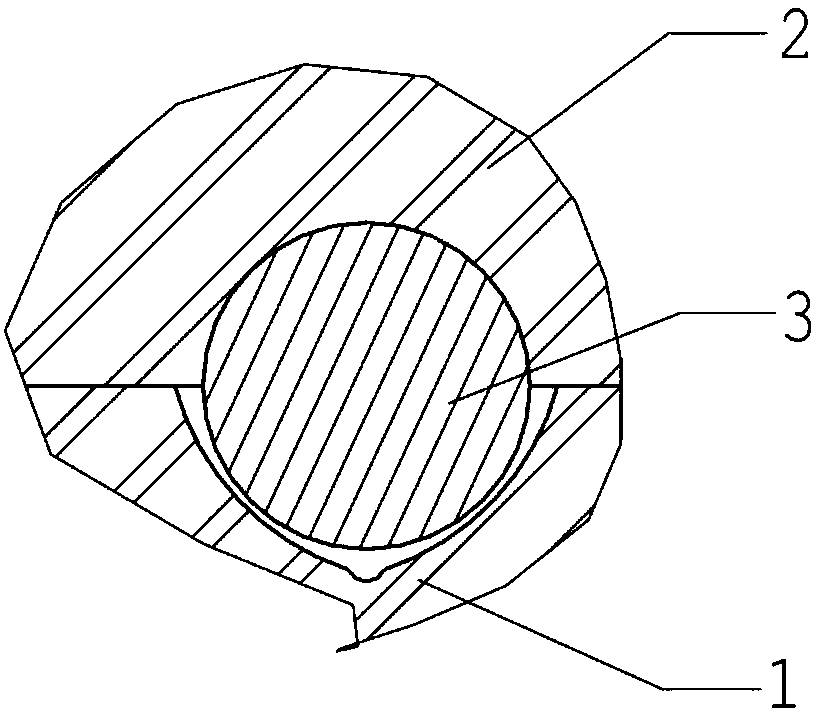

[0044] In order to meet the development needs of the industry, the storage performance of aerospace ball screws needs to be assessed. According to the long-term storage grease screening results and storage requirements, the above-mentioned grease storage accelerated test device was selected to conduct the grease storage accelerated test.

[0045] Apply long-storage grease to the raceway of the equivalent test device, and place it in an environment with high oxygen concentration, high pressure and high temperature for the test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com