ESL accurate edge-cutting and film-covering device and technique

A lamination and precise technology, applied in mechanical equipment, lamination devices, lamination auxiliary operations, etc., can solve the problems of leather rebound, excessive stretching of leather, affecting the quality of lamination, etc., to avoid excessive tension, Improve efficiency and save labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

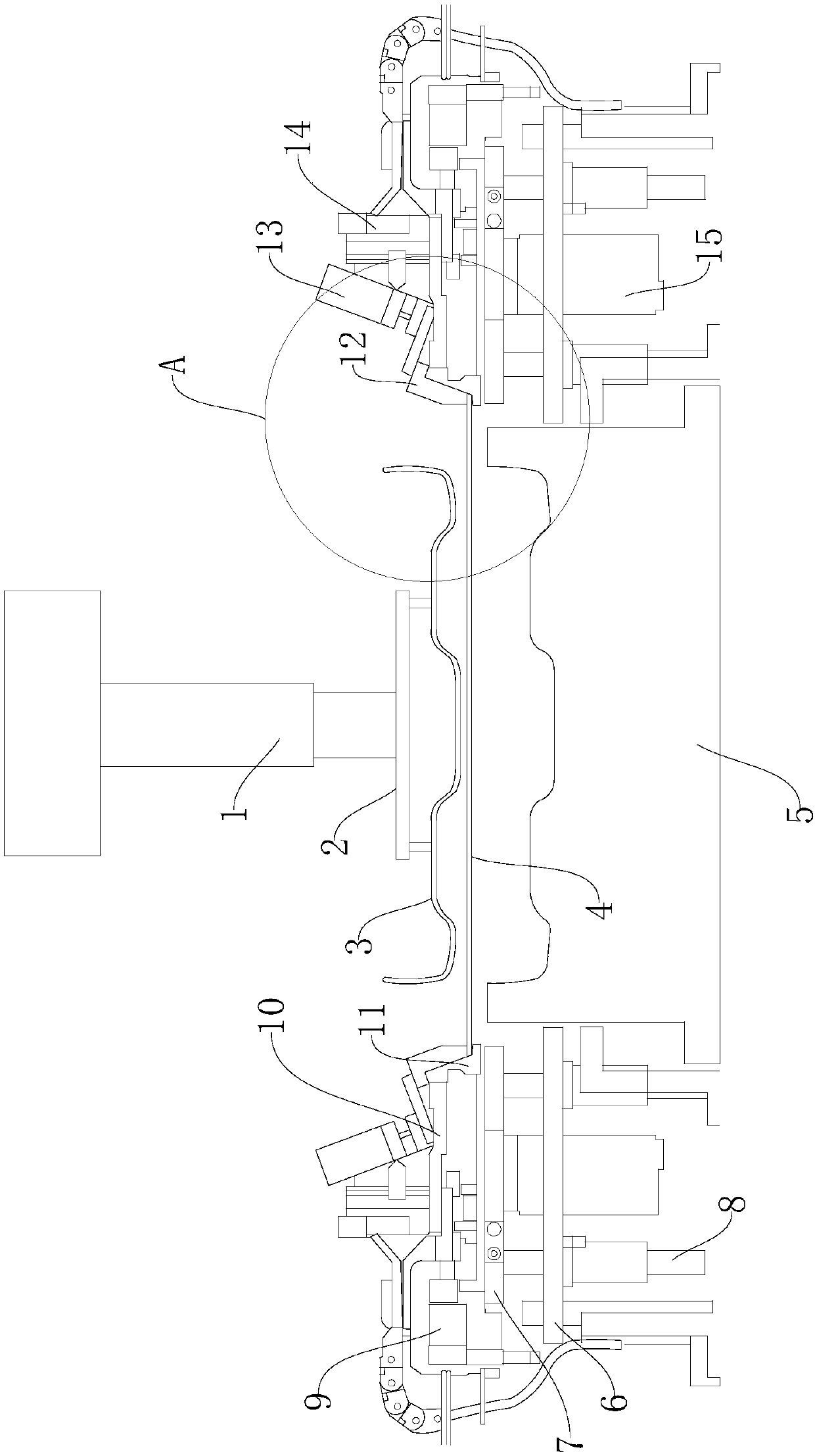

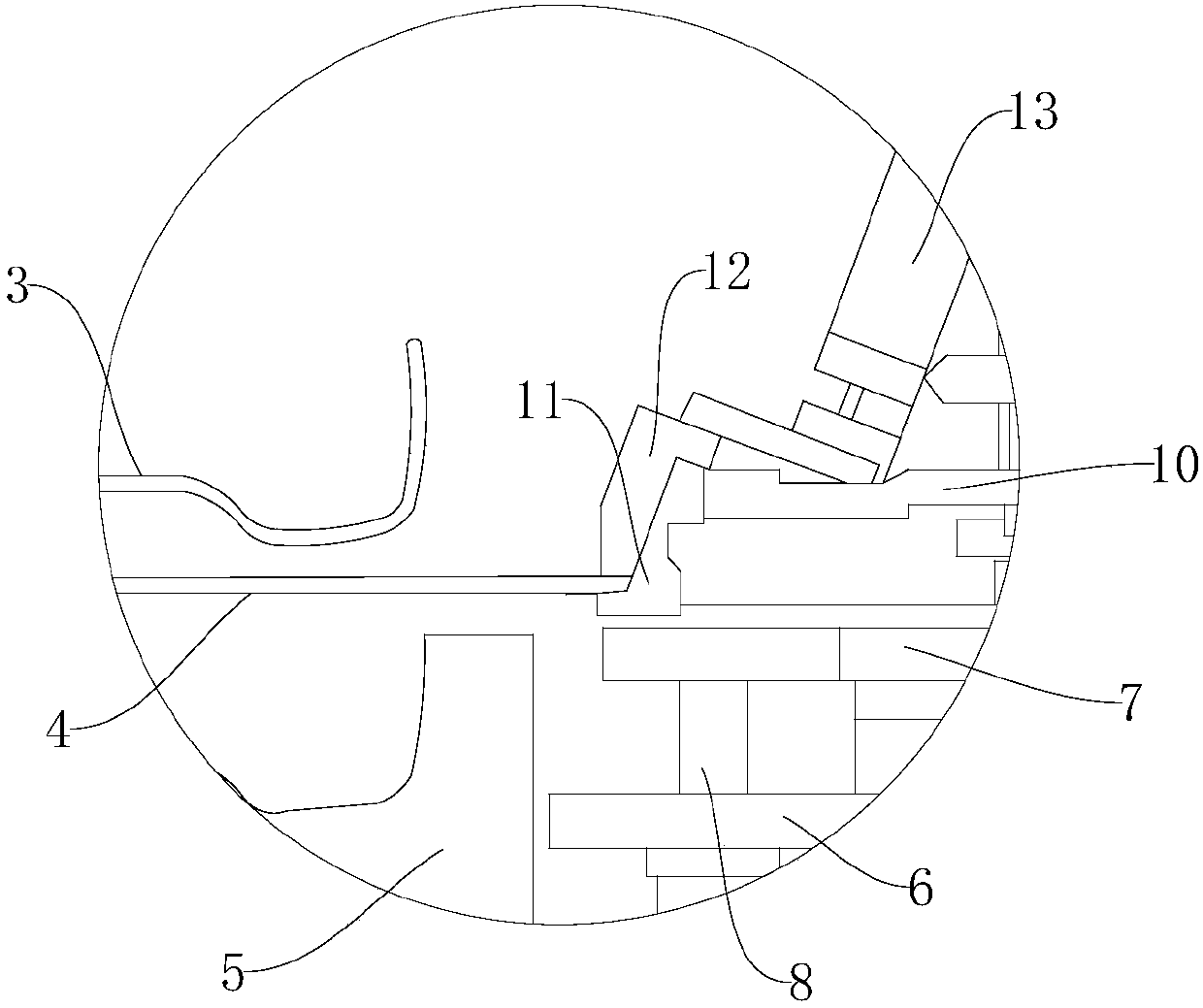

[0041] Such as figure 1 , figure 2 As shown, this embodiment discloses an ESL precise trimming and laminating device, including a complete machine controller 15, an upper tooling and a lower tooling, the complete machine controller 15 is connected with the upper tooling and the lower tooling respectively, and the complete machine controller 15 controls the upper The coordinated operation of the tooling and the lower tooling facilitates the precise cooperation of the laminating and hemming processes.

[0042] The upper tooling includes a workpiece fixing mechanism 2 and a workpiece lifting mechanism 1 . The workpiece lifting mechanism 1 comprises a telescopic rod, the upper end of the telescopic rod is a fixed end, and the lower end of the telescopic rod is a movable end. In this embodiment, the telescopic rod adopts an electrically driven telescopic rod.

[0043]The movable end of the telescopic rod is connected with the workpiece fixing mechanism 2, and the workpiece fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com