Improved rotary drilling rig and construction method

A construction method and technology of rotary drilling, which are applied in drilling equipment and methods, drilling equipment, earthwork drilling, etc., can solve the problems of inconvenient handling, increased construction difficulty, and impact on construction progress, so as to avoid the quality of pile foundations. Accidents, increased efficiency of lowering, and the effect of preventing hole collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

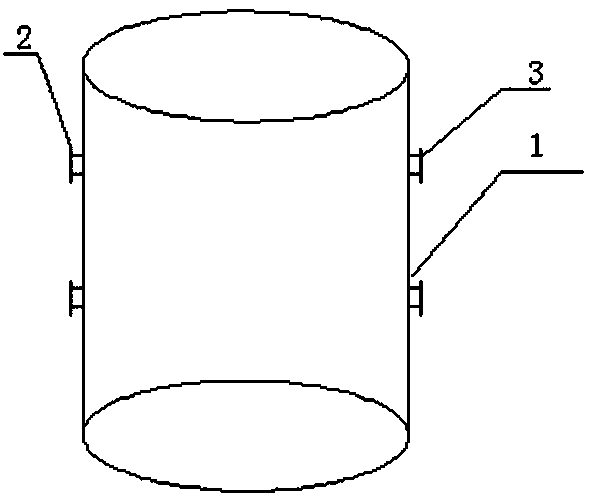

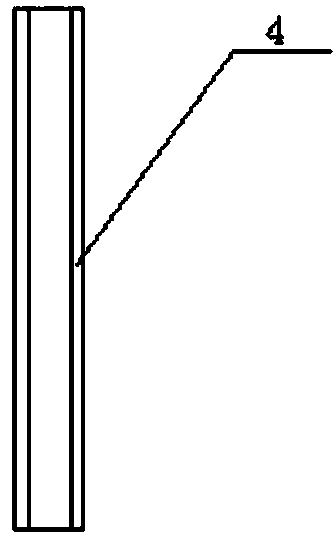

[0027] Such as Figure 1-5 As shown, an improved rotary drilling drill includes a steel casing 1, a grooved rail 4, a sleeve rod 7 and a sleeve body 9, the side wall of the steel casing 1 is provided with a snap ring 2 and a clamping post 3, and the grooved rail 4 is a horseshoe-shaped structure, the middle part of which is a cavity, the front end of the sleeve rod 7 is provided with a ferrule 5, and the rear end of the ferrule 5 is provided with a ferrule rod 6, and the sleeve rod 7 cooperates with the ferrule rod 6. The front end of the sleeve body 9 is provided with an extension end, the extension end is a two-wing structure, the sleeve rod 7 is movably connected with the extension end, and the sleeve body 9 is provided with a fixing bolt column 8 .

[0028] This embodiment also includes a construction method for an improved rotary drill, comprising the following steps:

[0029] A1. The position of the pile foundation is staked out during construction, and the rotary drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com