A functional strain, fermentation method, production method and application

A functional and bacterial strain technology, applied in the field of biocontrol Bacillus amyloliquefaciens and antagonistic bacteria, can solve the problems of agricultural product pesticide residues, human health threats, environmental pesticide pollution, etc., to reduce the amount of chemical fertilizers, reduce pesticide residues and pollution, The effect of reducing the use of pesticides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0049] 1. Microbial liquid: the formula of the strain fermentation medium is 25g of corn flour, 25g of bean cake powder, 1g of urea, 3g of sucrose, K 2 HPO 4 1.2g, MgSO 4 0.3g, MnSO 4 0.2, bubble enemy 0.3g, pH 7.2, add water to 1000ml. The effective number of viable bacteria in the microbial liquid is 1.49×10 10 individual / ml.

[0050] The fermentation conditions for liquid fermentation production of Bacillus amyloliquefaciens LVLE15 are: pH 6.5-8.0, culture temperature 30-45°C, initial rotation speed 120-200rpm, ventilation volume 0.5-1vvm, culture for 35-45 hours, middle and late stages of fermentation Spores are formed, the spore rate is as high as 93%, and the number of effective viable bacteria in the fermentation broth is above 15 billion / ml.

[0051] 2. Raw material formula: add according to the following formula. The trace element is borax and chelated zinc, the ratio is 1.5:3.5; the protective agent is sodium benzoate and molasses, the ratio is 1.5:2.

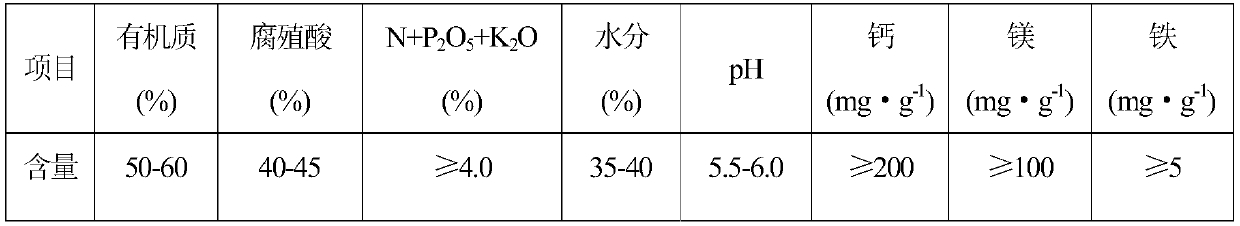

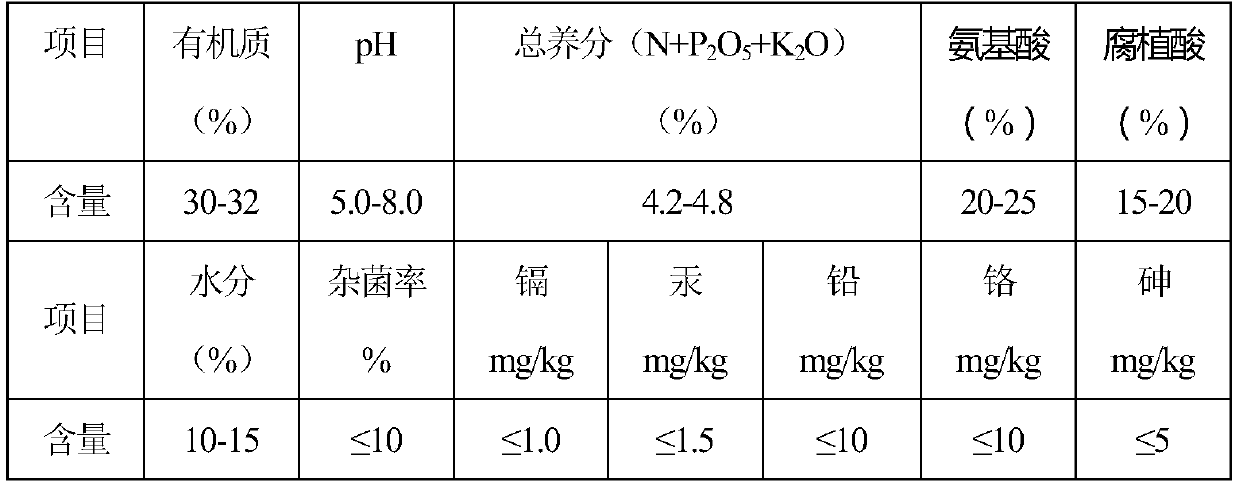

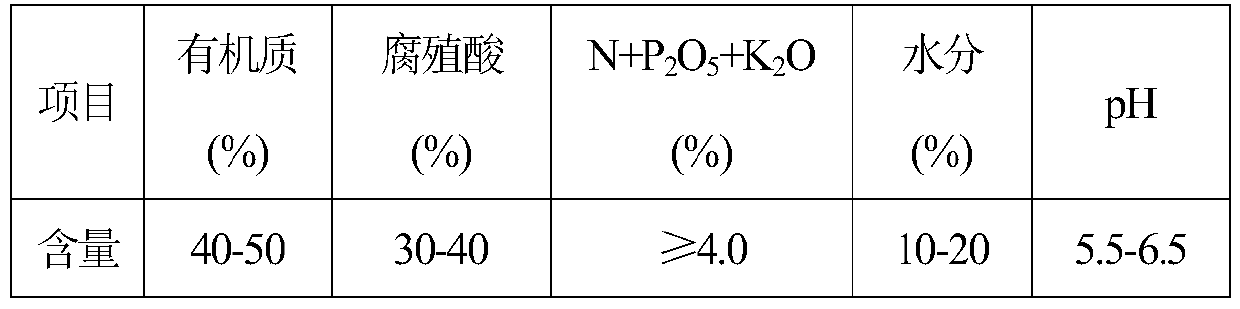

[0052]...

Embodiment 1-2

[0059] 1. Preparation of solid microbial agent: the fermented bacterial liquid of biocontrol Bacillus amyloliquefaciens LVLE15 is adsorbed with peat according to the ratio of bacterial liquid: peat = 1:5, and the effective number of viable bacteria of the compound bacterial agent after mixing reaches 1.2×10 9 more than one per gram, and the water content should be kept within 30%.

[0060] 2. Sampling. The hydrolysis slag produced in the amino acid production process was obtained from Henan Lianhua Monosodium Glutamate Co., Ltd.;

[0061] 3. pH adjustment: crush large pieces of hydrolyzed slag into powder or small particles, mix with powdered lime according to hydrolyzed slag:lime=4:1, pulverize with chain crusher and stack for 8-12 hours to allow it to fully react;

[0062] 4. Turn over: use a forklift or manually turn over the pile, let the temperature of the reacted material cool down to normal temperature;

[0063] 5. Pulverization: The hydrolyzed slag cooled to normal ...

Embodiment 1-3

[0071] 1. Preparation of solid microbial agent: the fermented bacterial liquid of biocontrol Bacillus amyloliquefaciens LVLE15 is adsorbed with peat according to the ratio of bacterial liquid: peat = 1:5, and the effective number of viable bacteria of the compound bacterial agent after mixing reaches 1.2×10 9 more than one per gram, and the water content should be kept within 30%.

[0072] 2. Sampling. The oil residue produced by adsorption during the salad oil production process was obtained from Shanghai Lichang Environment Co., Ltd.;

[0073] 3. pH conditioning: crush large pieces of oil residue into powder or small particles, mix it with powdered lime according to hydrolysis residue:lime=4:1, crush it with a chain crusher and stack it for 8-12 hours to allow it to fully react;

[0074] 4. Turn over: use a forklift or manually turn over the pile, let the temperature of the reacted material cool down to normal temperature;

[0075] 5. Pulverization: the oil residue cooled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com