Large cylindrical work piece bearer seat capable of being firmly positioned

A technology of cylindrical and supporting seats, which is applied in the field of supporting seats for large cylindrical workpieces, can solve problems affecting processing quality and workpieces affecting processing accuracy, and achieve the effects of improving construction efficiency, avoiding random rolling, and facilitating popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

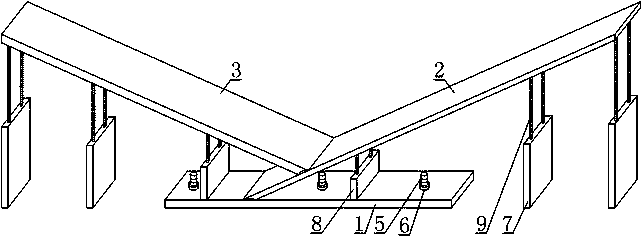

[0017] Such as figure 1 As shown, the support seat of a large cylindrical workpiece that can be firmly positioned includes a bottom mounting plate 1, a first support plate 2 and a second support plate 3, wherein the bottom mounting plate 1 is arranged horizontally, and the first support plate 2 is lower on the left and right The high slope is arranged and its left end is movably connected with the upper end surface of the bottom mounting plate 1, and the second support plate 3 is arranged with a high left and a right low slope and its right end is movably connected with the upward slope of the first support plate 2. In this embodiment, the angle between the first support plate 2 and the second support plate 3 can be adjusted within a range of 120°-140°.

[0018] A first positioning block 7 and a second positioning block 8 are arranged below both the first supporting plate 2 and the second supporting plate 3 of the present embodiment, and the first positioning block 7 is arrang...

Embodiment 2

[0022] In order to avoid overturning when the large cylindrical workpiece is put on hold in this embodiment, this embodiment makes the following further limitations on the basis of Embodiment 1: this embodiment also includes a connecting screw 5 and a lock nut 6, wherein the connecting wire The rod 5 is arranged vertically and its lower end passes through the bottom mounting plate 1 and is embedded in the ground. When this embodiment is specifically set up, the bottom mounting plate 1 is formed with a plurality of positioning perforations that run through its upper and lower end faces, and any two adjacent positioning perforations are arranged at a certain distance in the transverse direction, and the connecting screw rod 5 passes through the positioning perforations. Through the bottom mounting plate 1 , each positioning through hole corresponds to a connecting screw 5 , and each connecting screw 5 is correspondingly provided with a locking nut 6 .

[0023] In this way, when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com