Wood equidistant cutting device for stool leg manufacturing

An isometric cutting, wood technology, applied in sawing equipment, unloading equipment, sawing components, etc., can solve the problems of slow cutting efficiency, high labor intensity, cumbersome operation, etc., to reduce labor intensity, improve cutting efficiency, The effect of preventing random scrolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

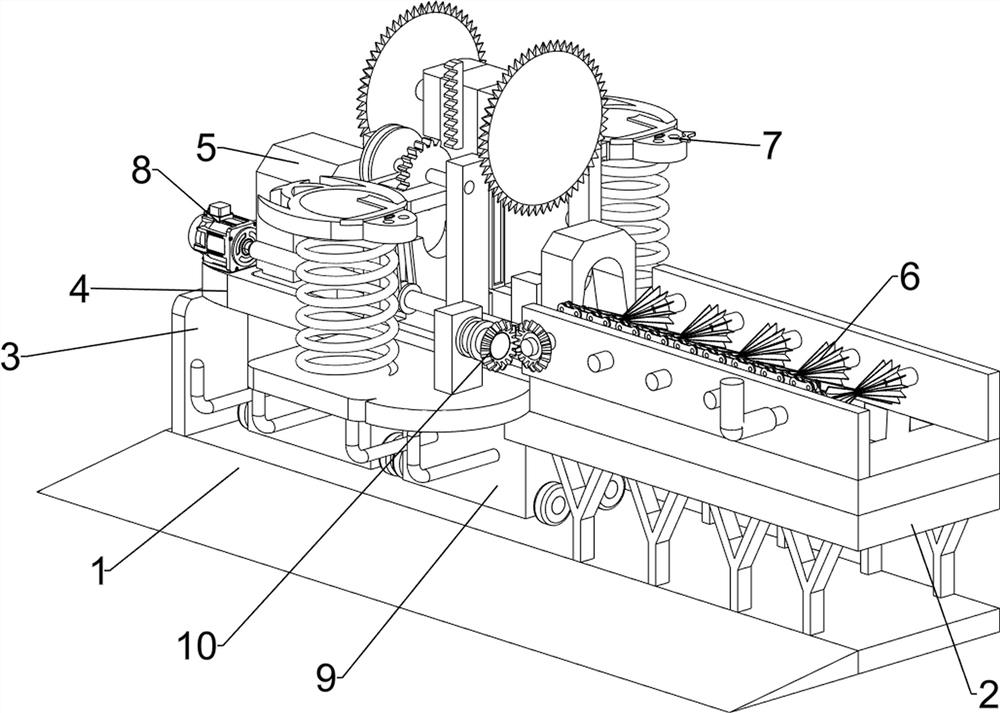

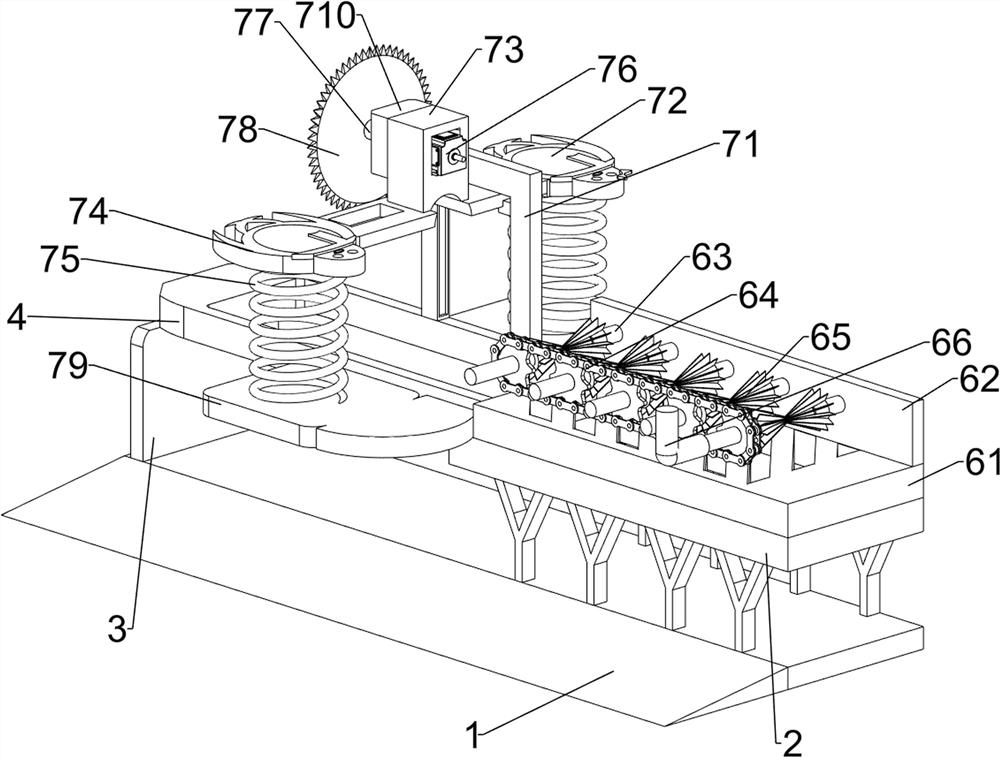

[0027] An equipment for isometric cutting of wood for making stool legs, such as Figure 1-3 As shown, it includes a bottom plate 1, a support platform 2, a support 3, a mounting plate 4, a limit assembly 5, a transport mechanism 6, and a cutting mechanism 7. The top right side of the bottom plate 1 is connected to the support platform 2, and the top left side of the bottom plate 1 is connected There is a support 3, an installation plate 4 is connected between the top of the support 3 and the top of the support platform 2, the top of the installation plate 4 is provided with a limit assembly 5, the top of the support platform 2 is provided with a transport mechanism 6, and the top of the installation plate 4 is provided with a cutting mechanism 7.

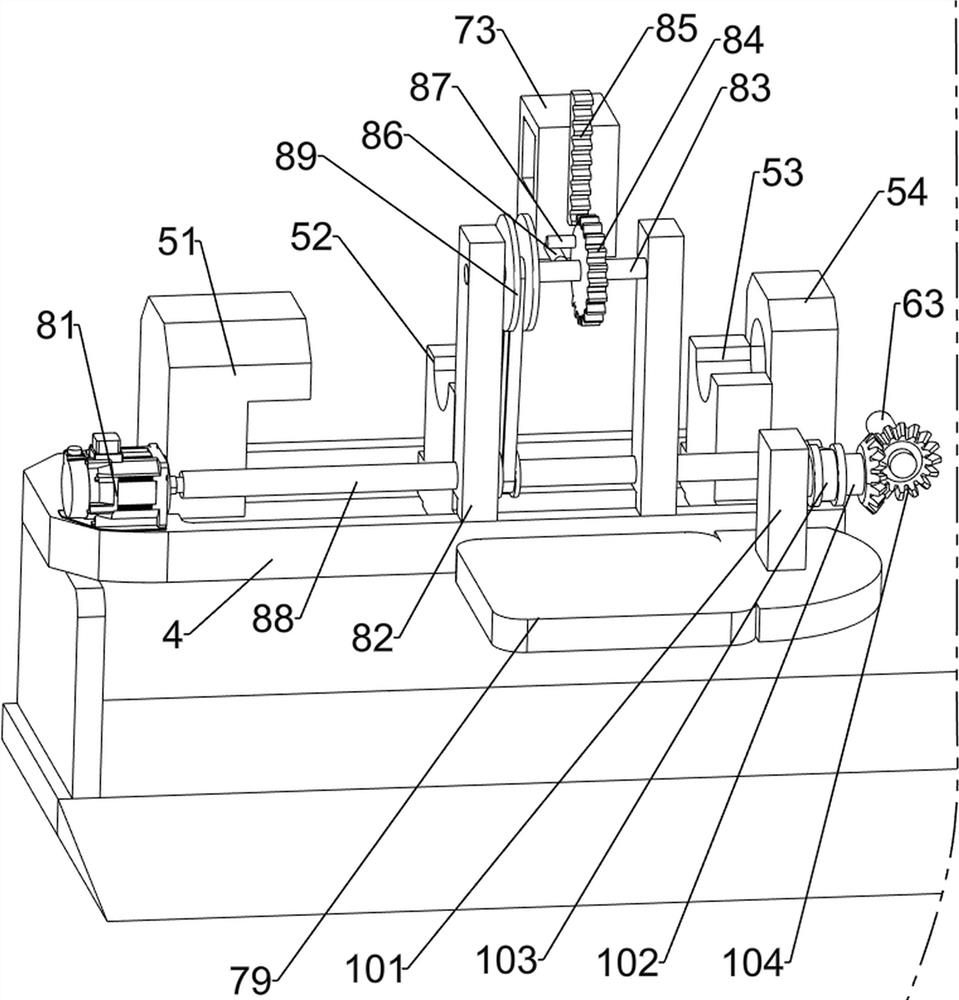

[0028] The limit assembly 5 includes a limit plate 51, a first support seat 52, a second support seat 53 and a guide seat 54. The limit plate 51 is connected to the top left side of the installation plate 4, and the first support s...

Embodiment 2

[0033] On the basis of Example 1, such as figure 1 and image 3As shown, drive mechanism 8 is also included, and drive mechanism 8 includes servo motor 81, fixed plate 82, rotating rod 83, missing gear 84, rack 85, movable rod 86, driving rod 87, rotating rod 88 and the first belt Transmission group 89, servo motor 81 is installed on the left front side of the top of mounting plate 4, two fixed plates 82 are connected to the front side of the top of mounting plate 4, and a rotating rod 83 is connected in rotation between the two fixed plates 82 tops, and on the rotating rod 83 Connected with missing gear 84, housing 73 front side is connected with rack 85, rack 85 cooperates with missing gear 84, housing 73 front side is connected with movable rod 86, movable rod 86 is positioned at the left side of rack 85, missing gear The left side of 84 is connected with driving lever 87, and driving lever 87 cooperates with movable rod 86, and between two fixed plates 82 bottoms, rotatin...

Embodiment 3

[0036] On the basis of Example 2, such as figure 1 and Figure 4 As shown, it also includes a collection mechanism 9, the collection mechanism 9 includes a collection box 91, wheels 92 and pull rods 93, two collection boxes 91 are placed on the left side of the top of the base plate 1, and the collection box 91 is located on the right side of the support 3, collecting Both left and right sides of box 91 are connected with two wheels 92 symmetrically in rotation, and the front side of collecting box 91 is connected with two pull rods 93 symmetrically.

[0037] The cut wood piece falls into the collection box 91 thereupon, so the wood piece cut can be collected by the collection box 91, and when the collection box 91 is full, the pull bar 93 can be pulled forward, and the collection box 91 is thereupon Move forward, and the wheel 92 rotates thereupon, then the wood block in the collection box 91 can be poured out, and then the collection box 91 is put back on the base plate 1; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com