Welded fixing seat with adjustable positioning structure

A positioning structure and fixing seat technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems affecting welding efficiency, welding accuracy, welding operation, applicability and practical limitations, etc., and achieve improvement Ease of use, good practicability, and the effect of saving operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

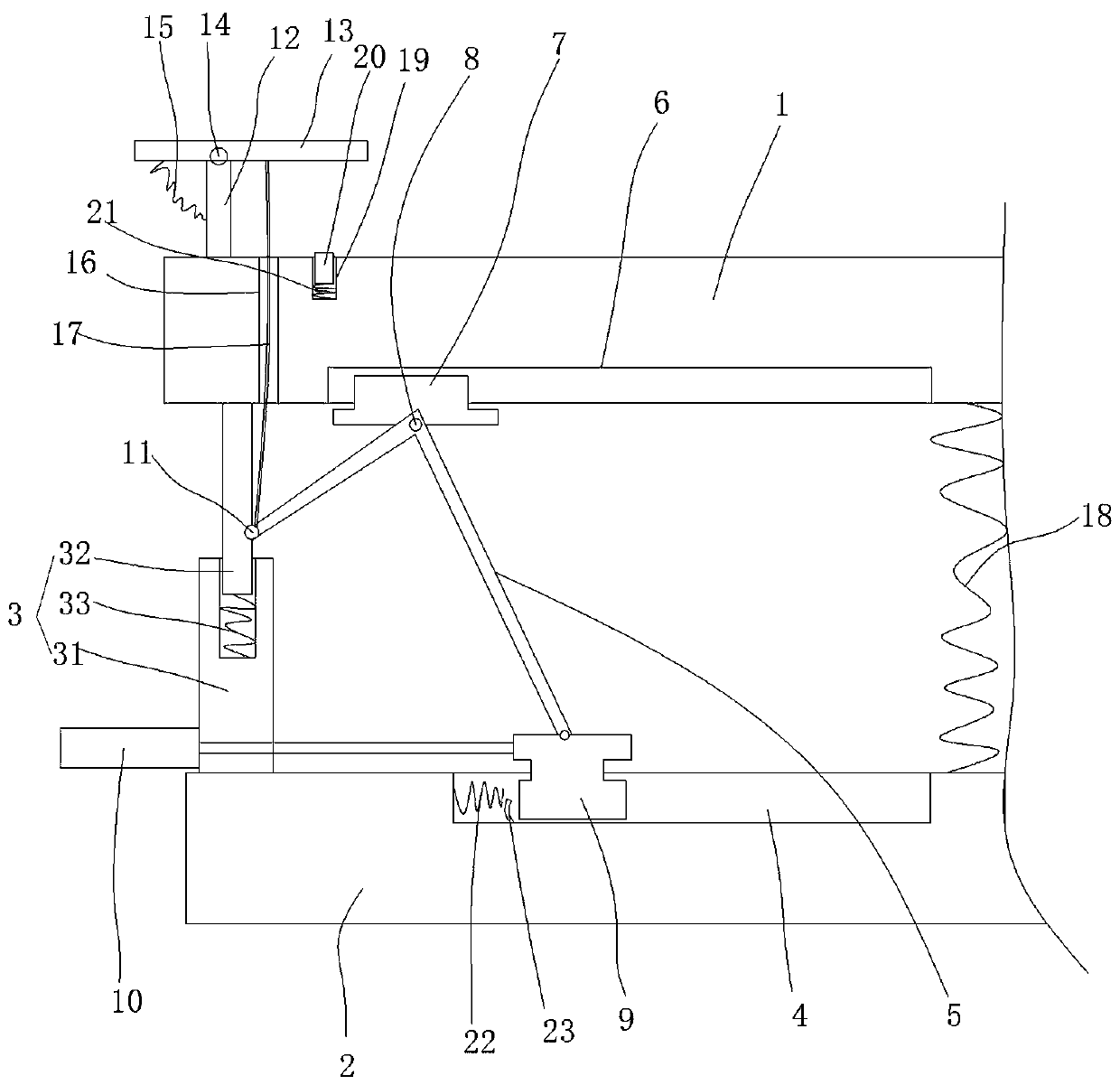

[0014] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0015] See figure 1 , a welding fixing seat with an adjustable positioning structure, comprising a welding fixing seat 1, a positioning structure is arranged at the bottom of the welding fixing seat 1, and the positioning structure includes a chassis 2, which is arranged on the top surface of the chassis The vertical telescopic struts 3 on both sides are provided with a guide chute 4 on the top surface of the underframe, and are also provided with an adjustable V-shaped plate 5, and a moving groove 6 is provided on the bottom surface of the welding fixed seat 1, A moving slider 7 is arranged in the moving groove 6, and the corner of the adjusting V-shaped plate 5 is connected to the bottom surface of the moving slider 7 through a movable shaft 8, and one end of the adjusting V-shaped plate 5 is passed through a sliding The block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com