Revolving bar pressing connection device and actuator installing and overturning system

A technology of crimping device and rotating rod, which is applied in the direction of transportation and packaging, conveyor objects, metal processing, etc., can solve the problems of low production efficiency, product batch difference, employee injury, etc., to improve stability and quality, Realize the effect of automatic operation and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

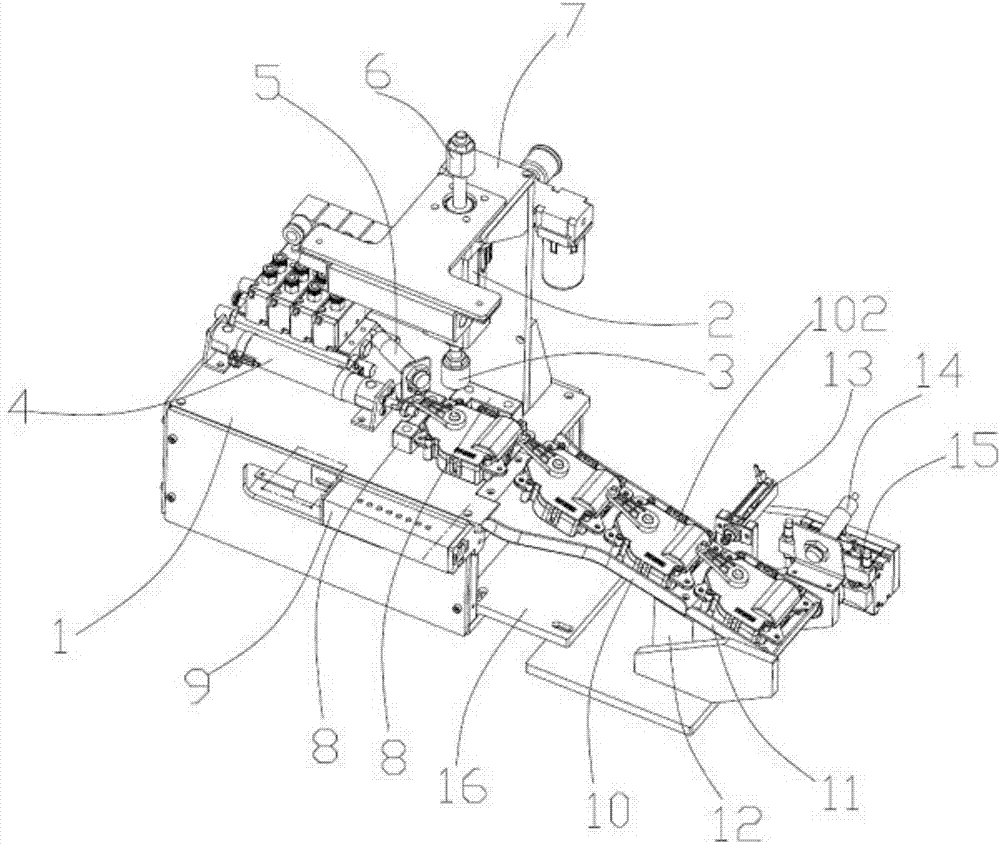

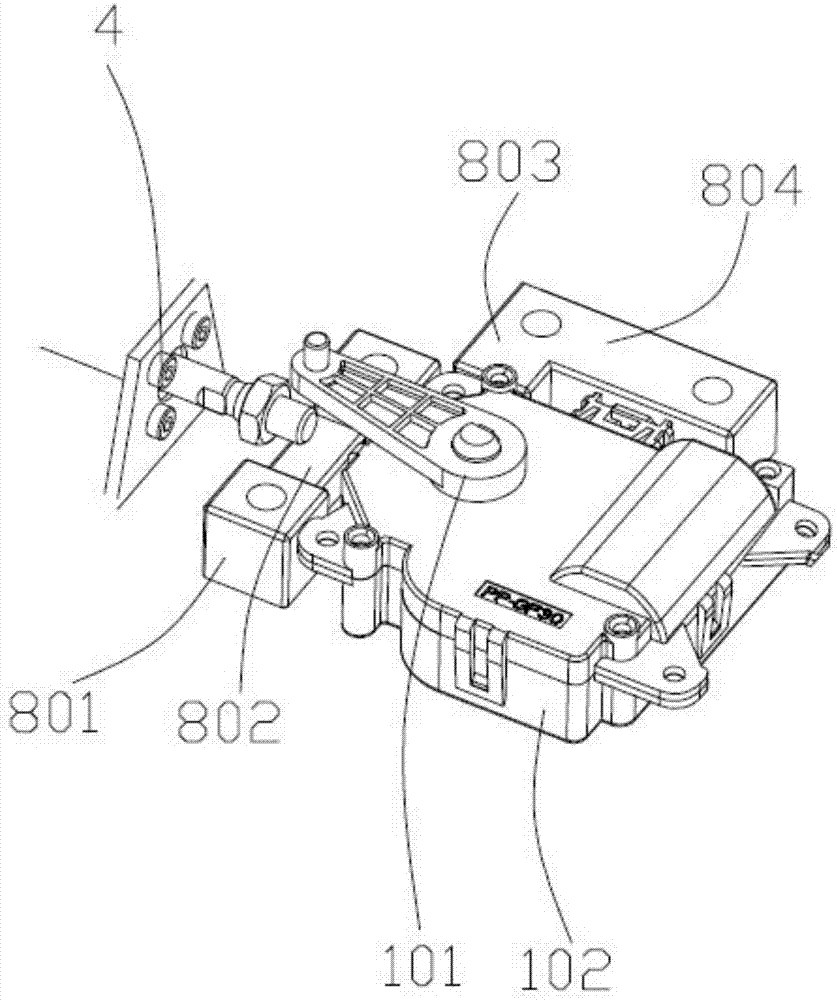

[0030] Such as figure 1 , the embodiment of the present invention provides a rotating rod crimping device, including a platform 1, a crimping drive mechanism, a positioning mechanism and a discharge mechanism.

[0031] The above-mentioned platform 1 is mainly used as an operation table, and the above-mentioned crimping drive mechanism, positioning mechanism and unloading mechanism, etc. can be installed on the platform 1, such as figure 1 , the platform 1 can be a rectangular parallelepiped pedestal structure, preferably installed horizontally, that is, the upper surface of the platform 1 is set horizontally, of course it is not limited to this, and this is easily determined and modified by those skilled in the art according to actual needs; the platform 1 It has a crimping station and a discharge channel. At the crimping station, the rotating rod 101 can be connected to the product 102 (in this embodiment, it is mainly the actuator 102, and of course it is also applicable to ...

Embodiment 2

[0036] Such as figure 1 , the embodiment of the present invention relates to an actuator installation and turnover system, including a crimping device for crimping the rotating rod 101 on the actuator 102 and an actuator 102 for crimping the rotating rod 101 Turn over to the turning device of the marking line, wherein the crimping device is preferably the rotating rod crimping device provided in the first embodiment above, and the specific structure of the rotating rod crimping device will not be repeated here. The discharge channel is connected to the turning device via a product transfer unit 10 .

[0037] As one of the preferred embodiments, such as figure 1 , the installation and turning system of the actuator also includes a stopper mechanism, the stopper mechanism is arranged beside the transfer channel formed by the product transfer unit 10, and has a function that can extend above the transfer channel or retract to the The material blocking member next to the transfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com