Stepping paddy rice weeder

A weeding machine, step-by-step technology, applied in the direction of harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of low grass efficiency, etc., and achieve the effect of low labor intensity, high production efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

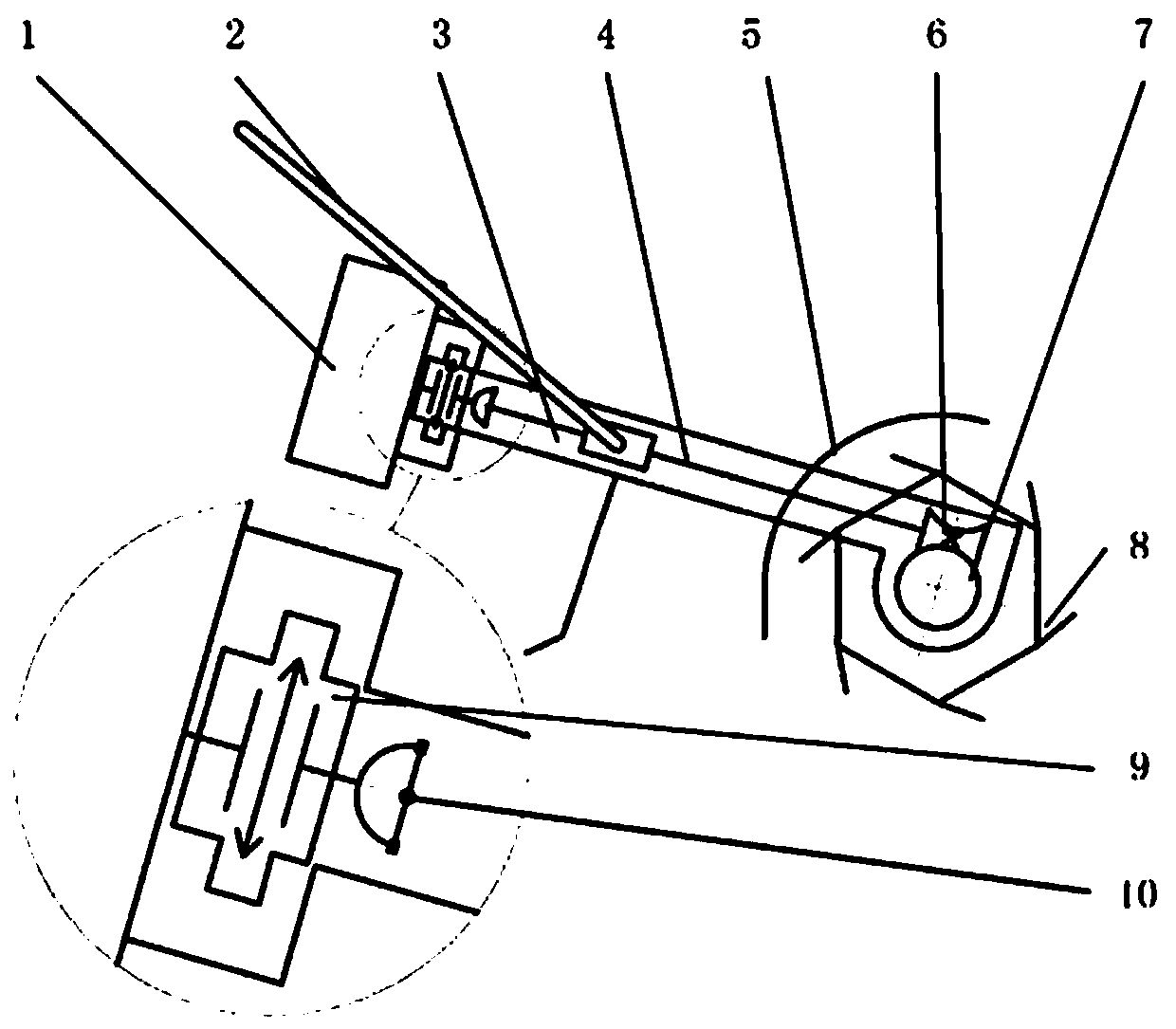

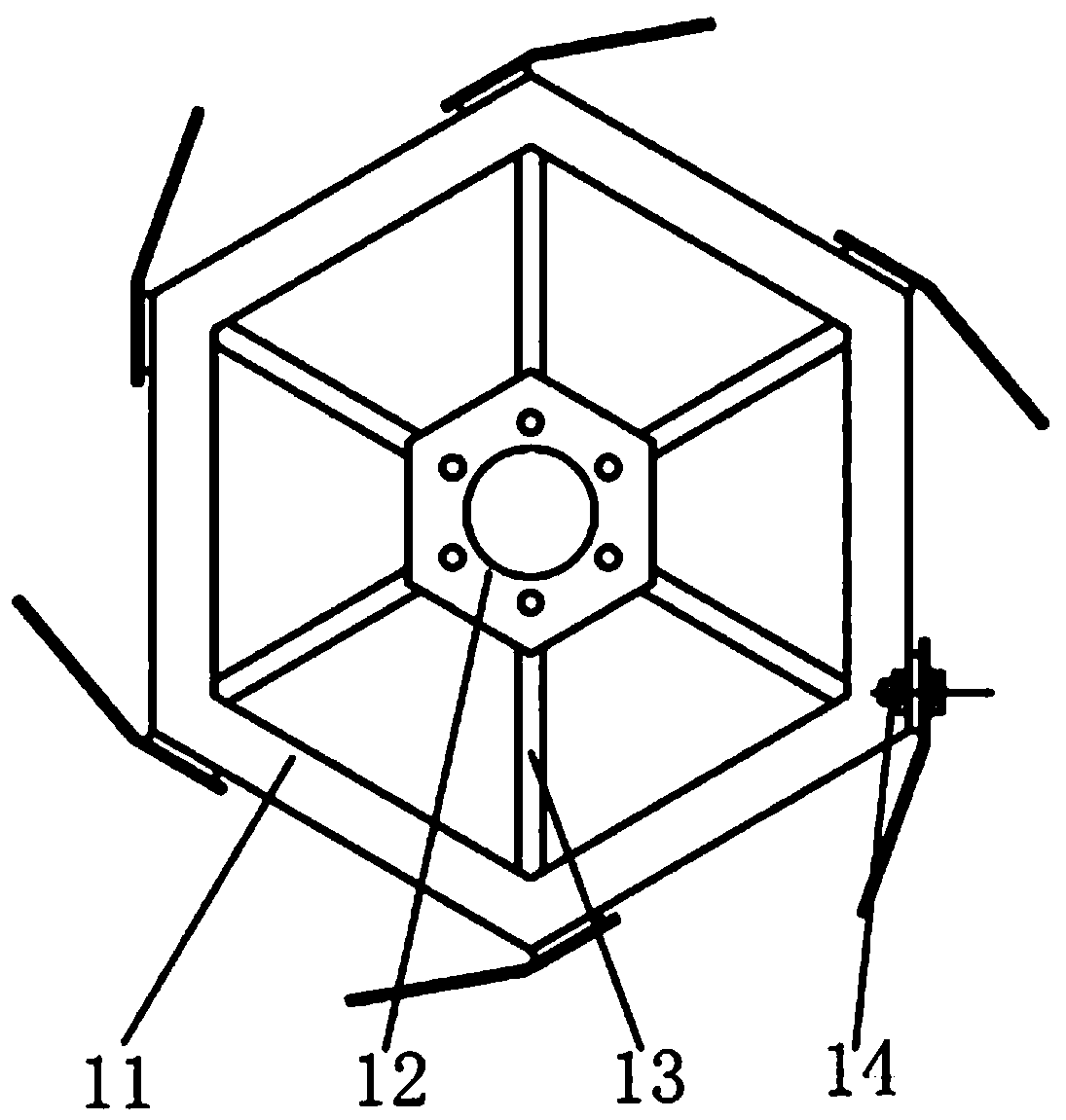

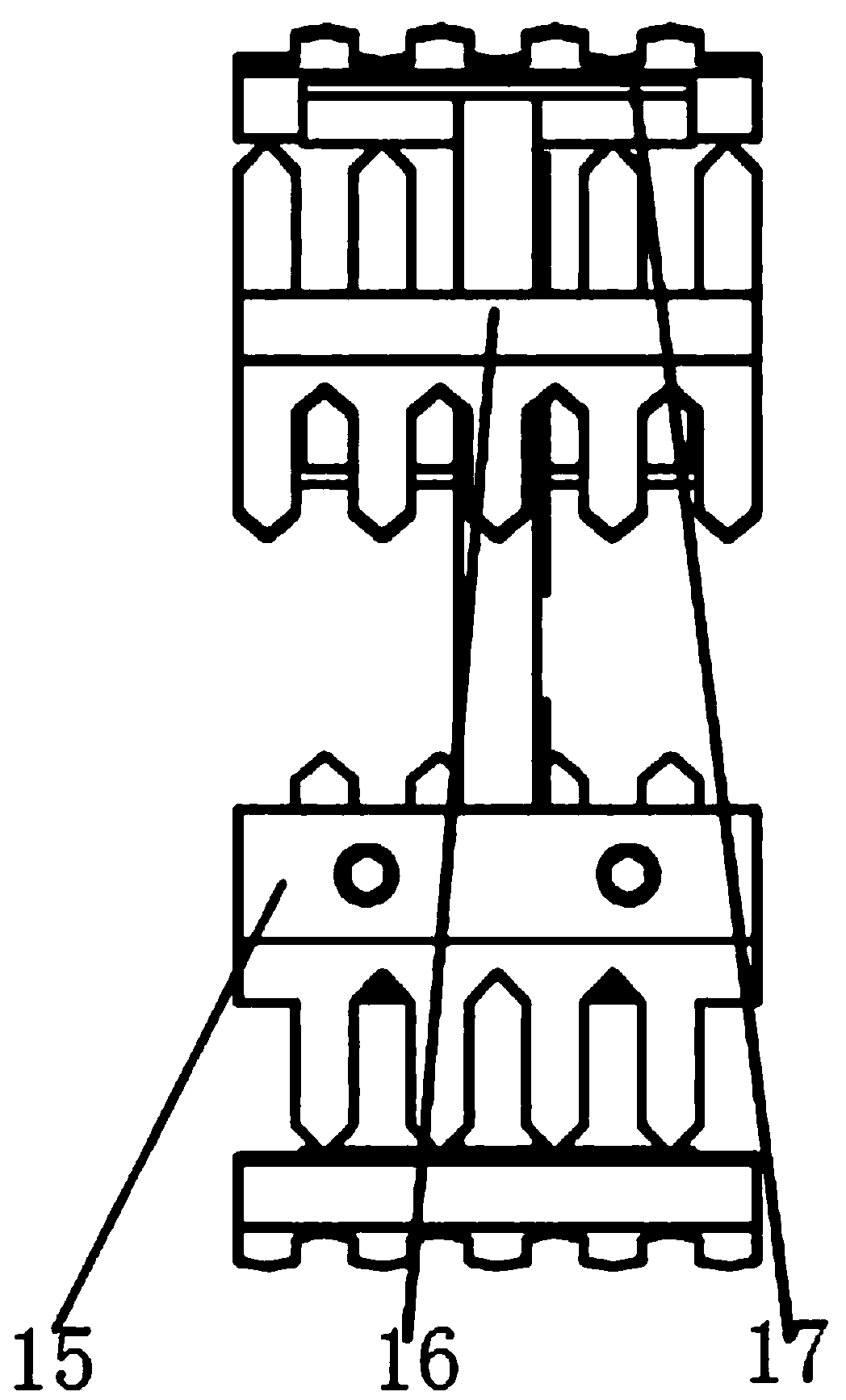

[0015] exist figure 1 Among them, including engine, handle, frame main beam, transmission shaft, mud shield, worm, worm gear, weeding wheel, friction ring clutch, universal coupling, among which the stepping paddy field weeder is powered by gasoline engine (1) Provide power to drive a pair of weeding wheels (8) to rotate weeds, and at the same time use the reaction force of the soil to provide power for the advancement of the weeder; during the rotation process, the weeding blades on the weeding wheel go down into the soil and rake the soil between the rows of rice. The weeds are buried under pressure; the tooth piece throws the soil backward during the unearthed process, which plays the role of loosening the soil and increasing the oxygen content of the soil; the power is transmitted to the transmission system through the friction ring clutch (9), and through the worm gear ( 7) The worm (6) transmission system decelerates, reverses directions and increases torque to drive the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com