Heat exchanger core for heat exchange between more than three fluids

A technology of heat exchangers and heat exchange fluids, which is applied in the direction of heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., and can solve problems such as inability to realize heat exchange of various fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

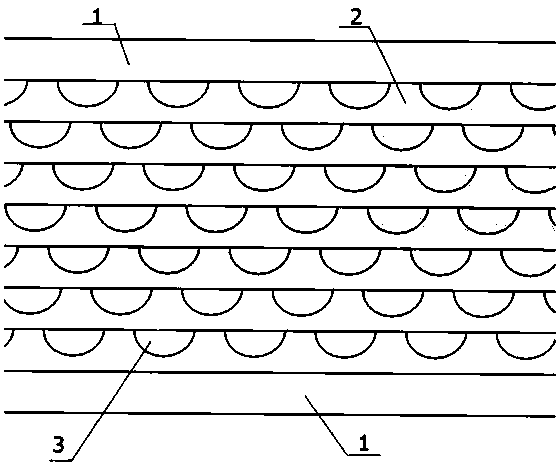

[0034] A heat exchanger core for heat exchange of three fluids: including flow channels and fluid inlets and outlets such as image 3 The heat exchange plate group 1 composed of the shown heat exchange plates, the heat exchange plate group 1 includes more than one such as image 3 The heat exchange plates shown also include flow channels and fluid inlets and outlets such as Figure 4 The heat exchange plate group 2 composed of the shown heat exchange plates, the heat exchange plate group 2 includes more than one such as Figure 4 The heat exchange plates shown also include flow channels and fluid inlets and outlets such as Figure 5 The heat exchange plate group 3 composed of the shown heat exchange plates, the heat exchange plate group 3 includes more than one such as Figure 5 The heat exchange plates shown; the heat exchange channels of all the heat exchange plates are located on one surface of the base body.

[0035] The core of the heat exchanger in this embodiment is ...

Embodiment 2

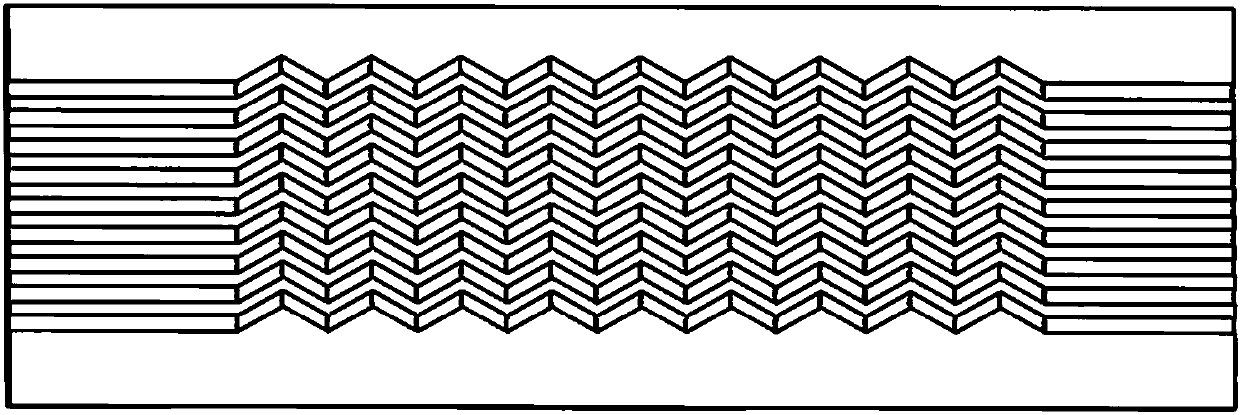

[0037] The difference from Embodiment 1 lies in that the heat exchange channels of the heat exchange plates are located on one or both sides of the substrate. One side of the heat exchange channels between adjacent heat exchange plates is not adjacent or adjacent, and a partition is provided between two adjacent heat exchange plates on one side of the heat exchange channel, and the partition is not etched The matrix of the heat exchange flow channel, one of the schematic diagrams of the core structure of the heat exchanger is shown in Figure 14 .

Embodiment 3

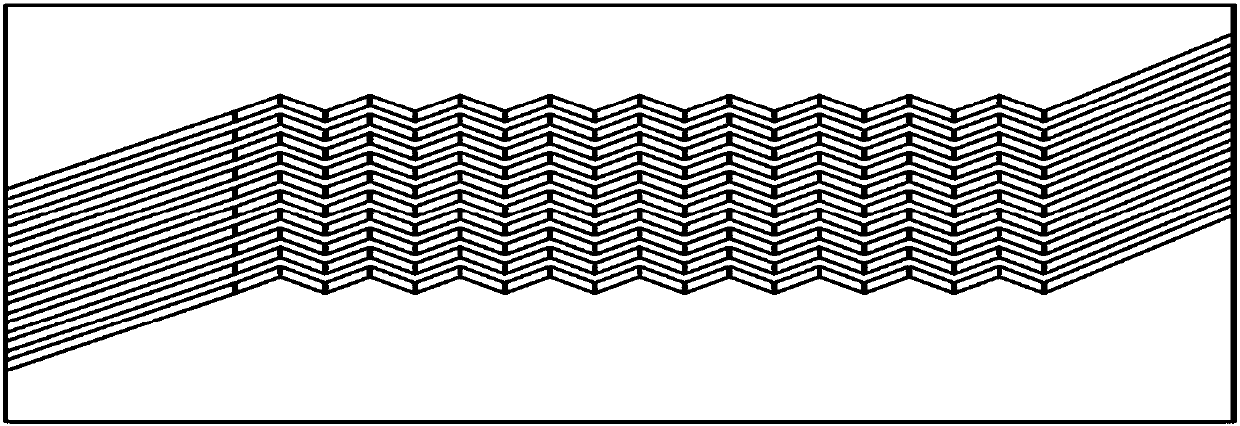

[0039] The difference with embodiment 1 is: the flow channel and the fluid inlet and outlet are image 3 The heat exchange plates shown are replaced with runners and fluid inlets and outlets as figure 2 The heat exchanger plate shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com