Automatic control shifting device based on synchronous belt and guide rail slider

A technology of shifting device and guide rail slider, applied in transmission control, components with teeth, belt/chain/gear, etc., can solve the problems of difficult modularization, serial production, sales and use, etc Simple structure, fast response and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

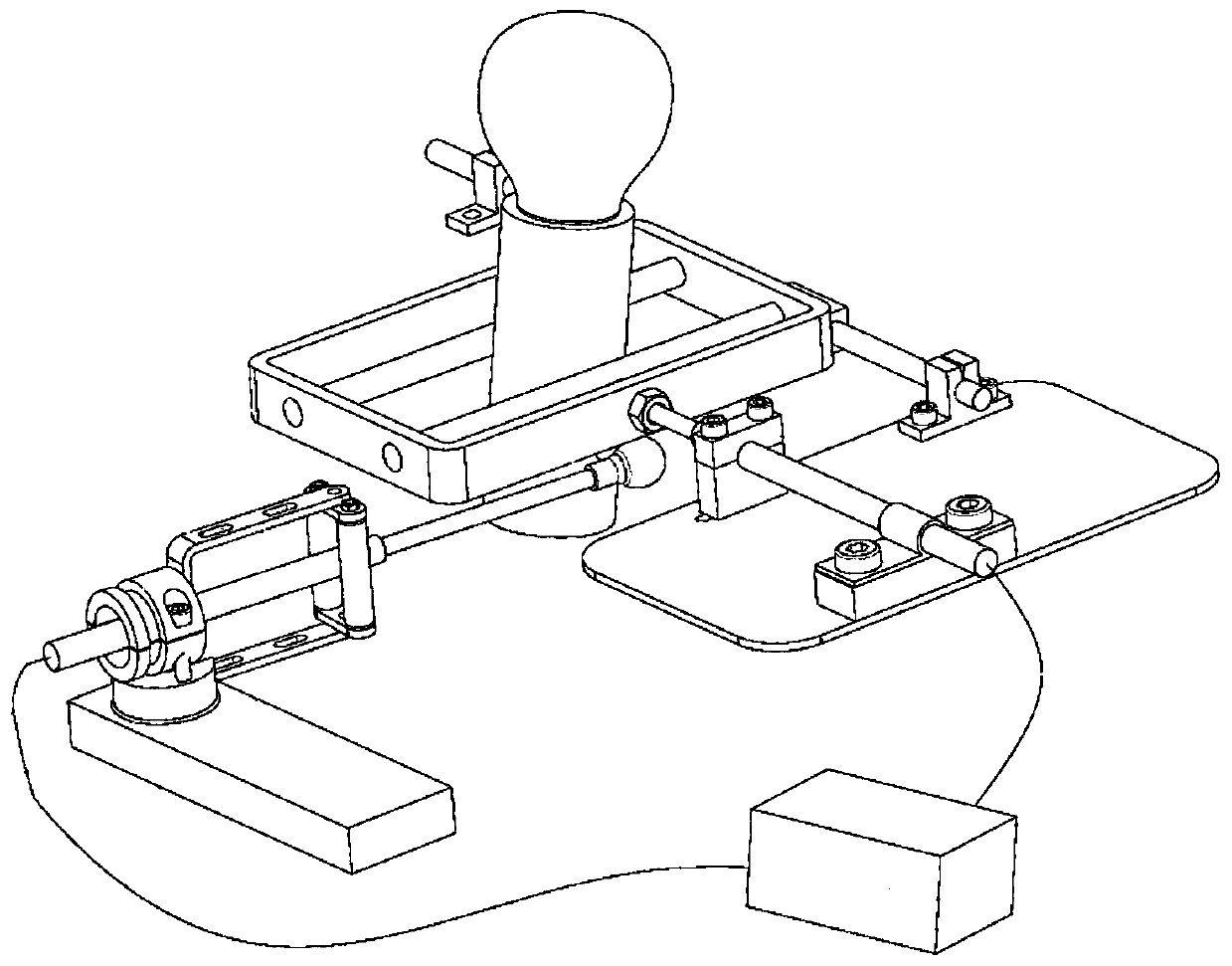

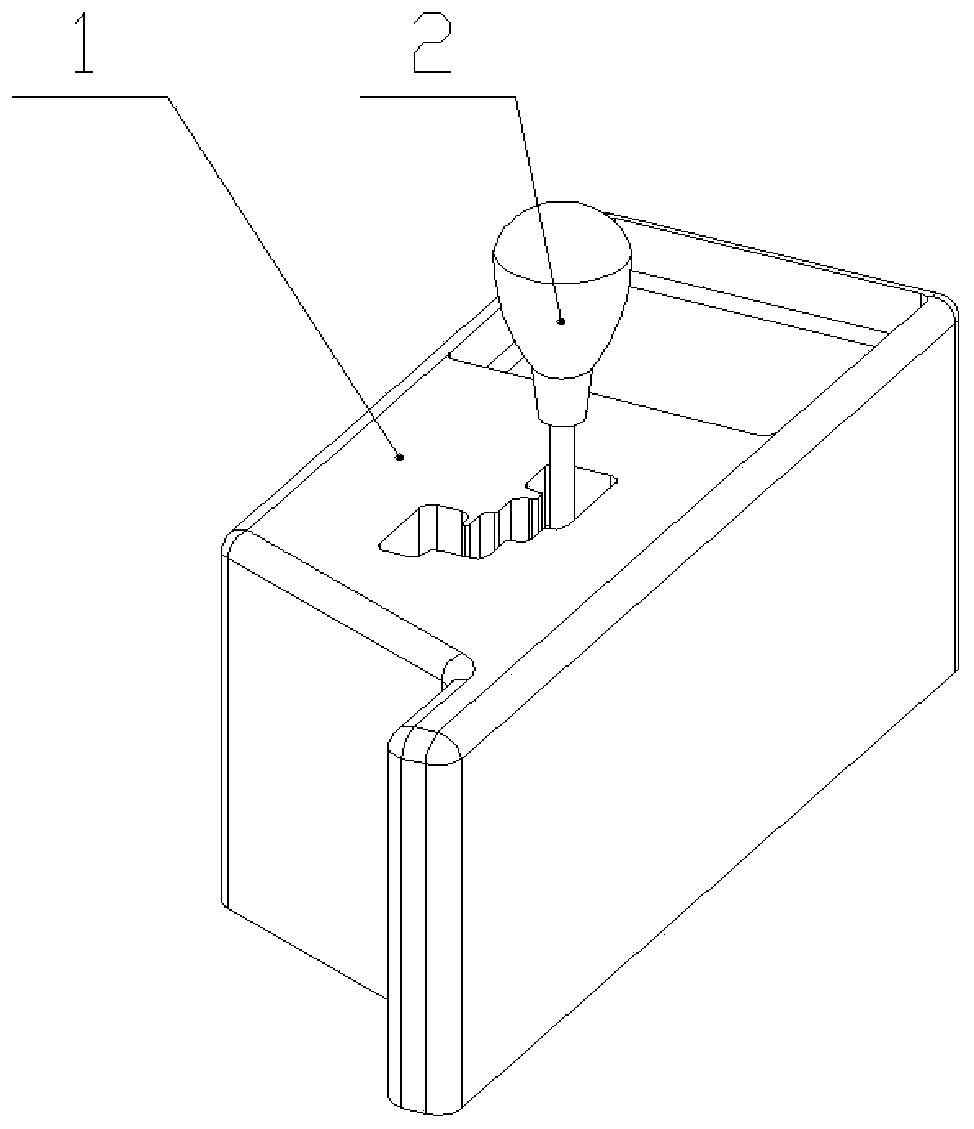

[0033] The gear shift mechanism of the original car is as image 3 As shown, the gear lever 2 moves in the serpentine guide groove, and when shifting gears, the gear lever 2 needs to cooperate with movement in the front and rear directions and in the left and right directions to realize gear shifting.

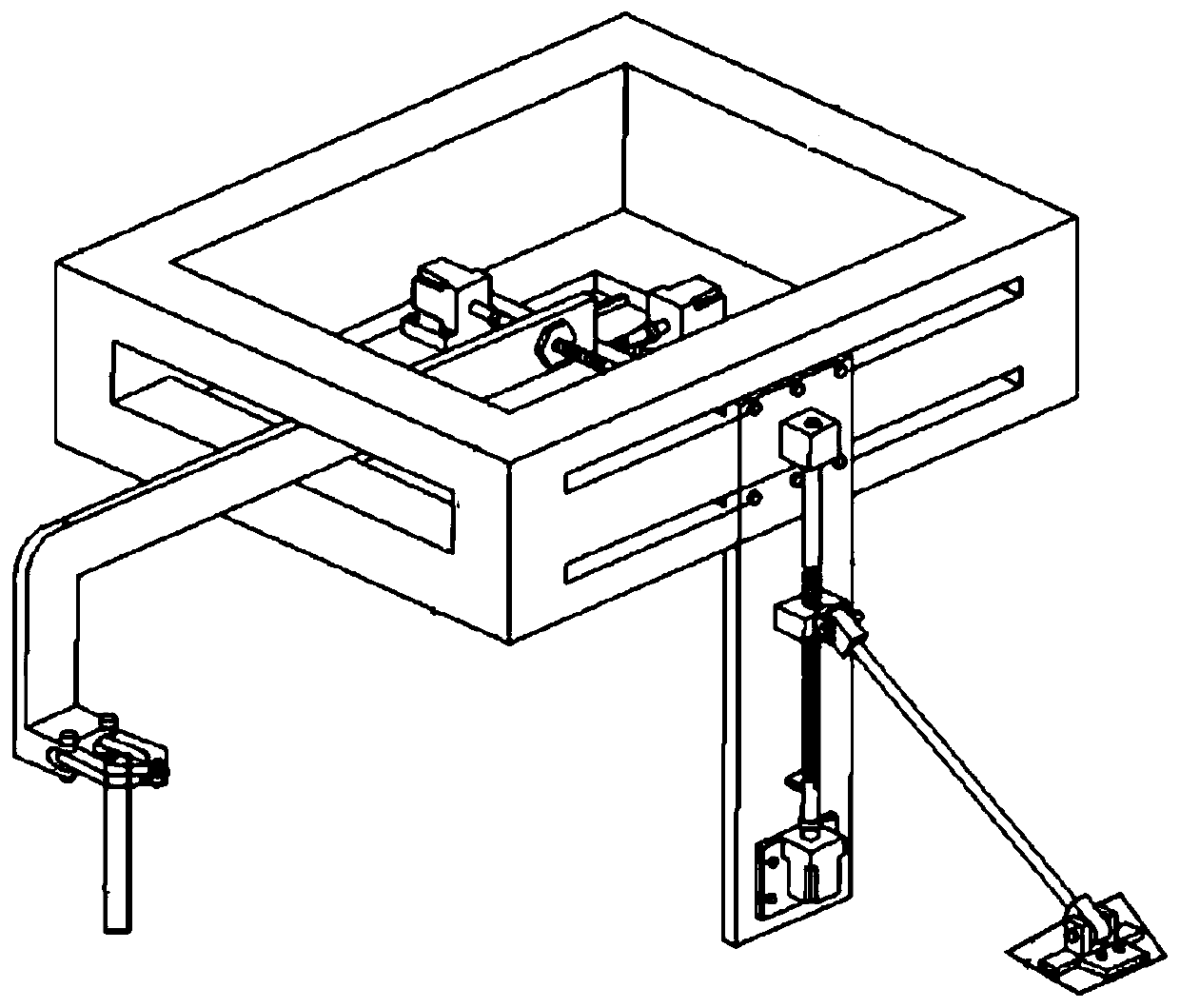

[0034] Such as Figure 4 , Figure 5 Shown, this shifting mechanism is installed and fixed in the hollow armrest box 1 inside. The fixed bracket 3 is positioned at the left and right sides of the gearshift mechanism, and the fixed bracket 3 is fixed on both sides of the hollow armrest box 1 by screws 6 to fix the gearshift mechanism with the hollow armrest box 1. Block handle 2 links to each other with b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com