Method for the control of the slip of a clutch device of a gearbox

A technology of clutch device and control device, which is applied in the direction of clutch, transmission control, components with teeth, etc., can solve the problems of increased fuel consumption, increased emissions, etc., and achieve the effect of reduced fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

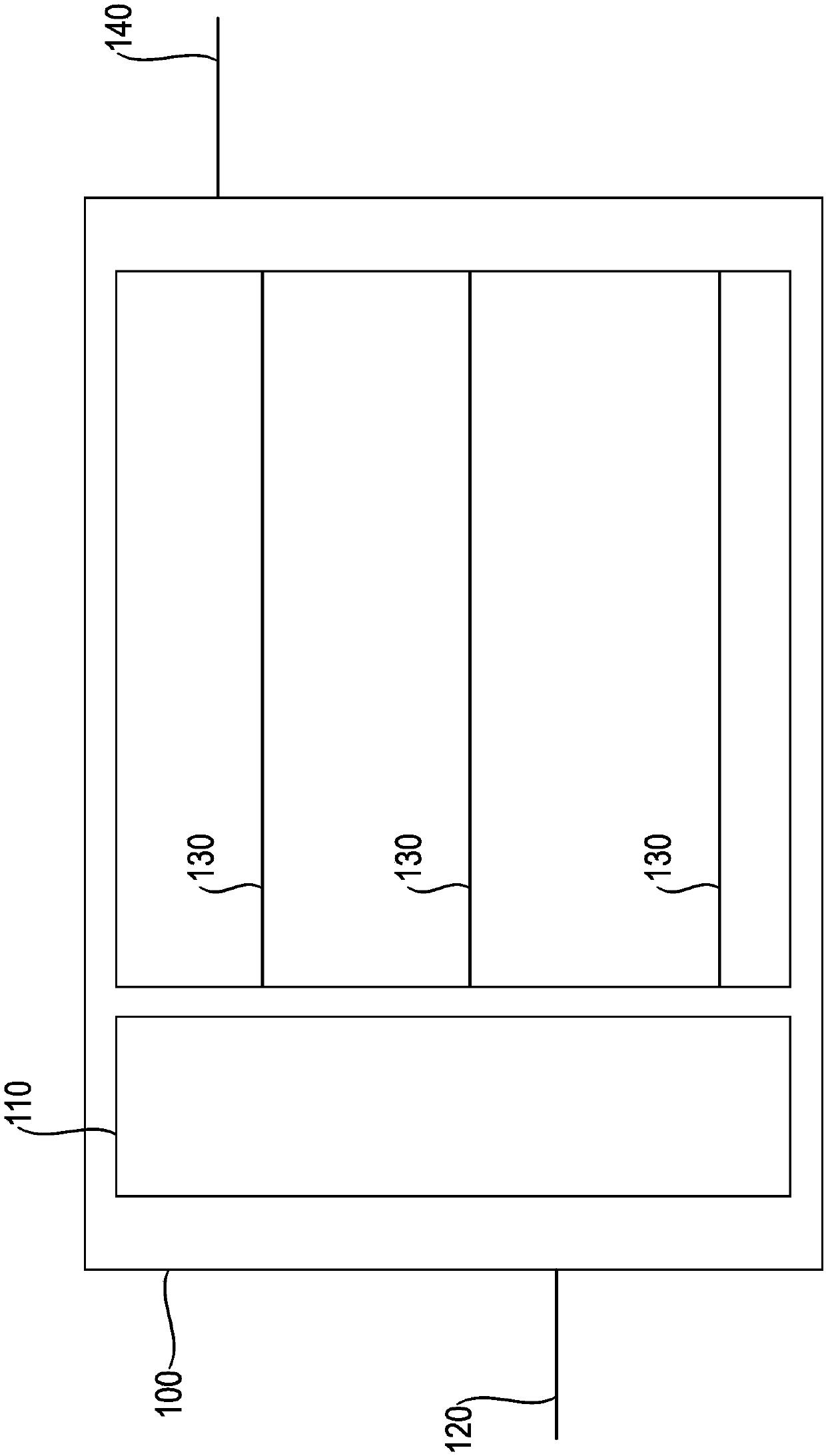

[0033] figure 1 It is schematically shown how the clutch device 110 makes it possible to couple the input shaft 120 with the output shaft 140 in the transmission 100 . In order to be able to ensure different transmission ratios, in this case three transmission shafts 130 are arranged in the transmission 100 so that three different transmission ratios can be selected via three different gears.

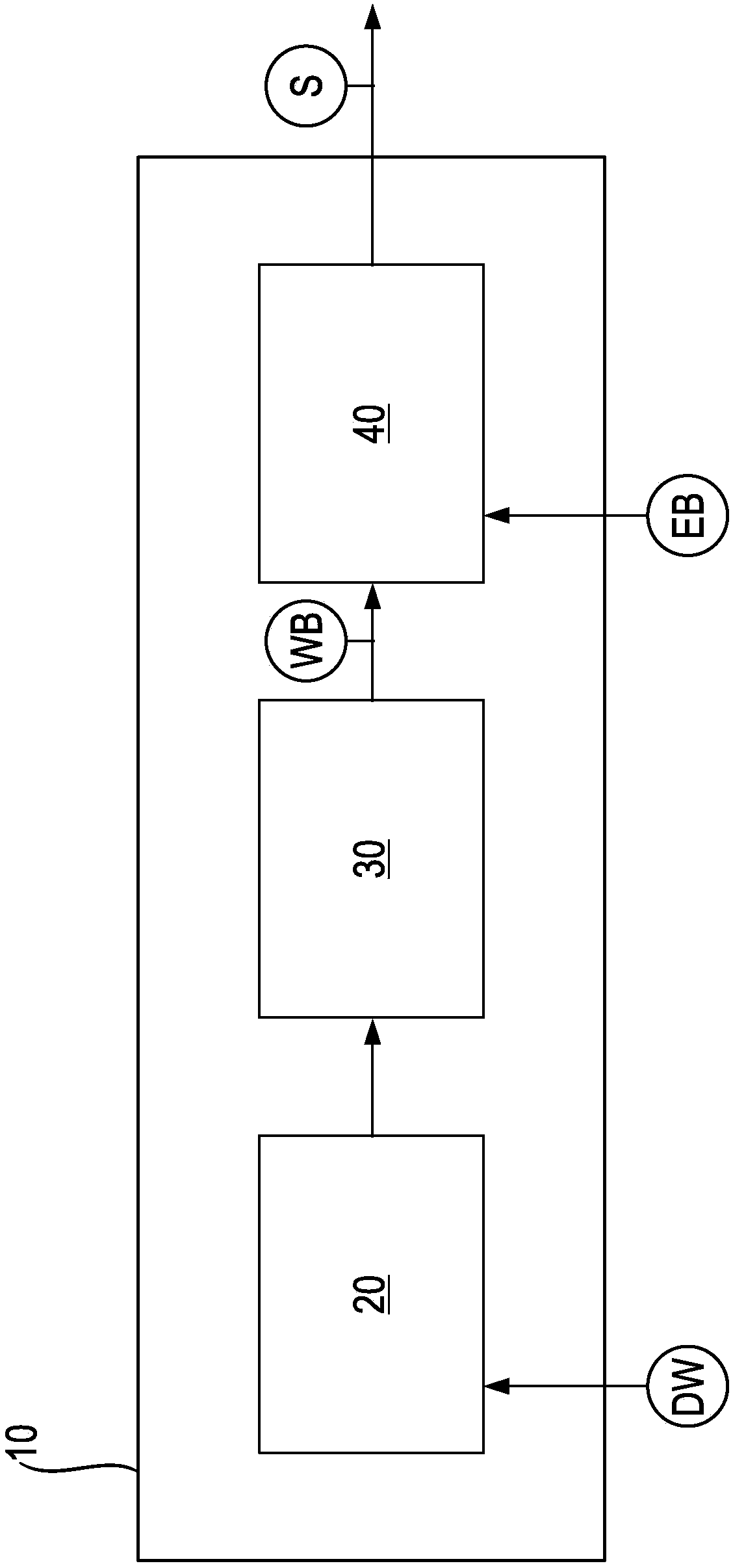

[0034] as in figure 2 schematically shown in, according to figure 1 The transmission 100 is equipped with a control device 10 . By means of the sensor unit 20 , a rotational speed value DW at the transmission shaft 130 can be determined. Based on this rotational speed value and in addition to the information of active transmission shaft 130 , determination unit 30 can then determine angular acceleration WB at determined transmission shaft 130 on the basis of this measured rotational speed value DW. This angular acceleration WB is passed on to the control unit 40, which then determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com