EVA (Ethylene-Vinyl Acetate) film

A kind of adhesive film, the same technology, applied in the direction of adhesive, film/sheet adhesive, film/sheet without carrier, etc., can solve the problems of reduced production speed, reduced production efficiency, low shrinkage rate, etc., to ensure production Effects of speed, productivity improvement, and low shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

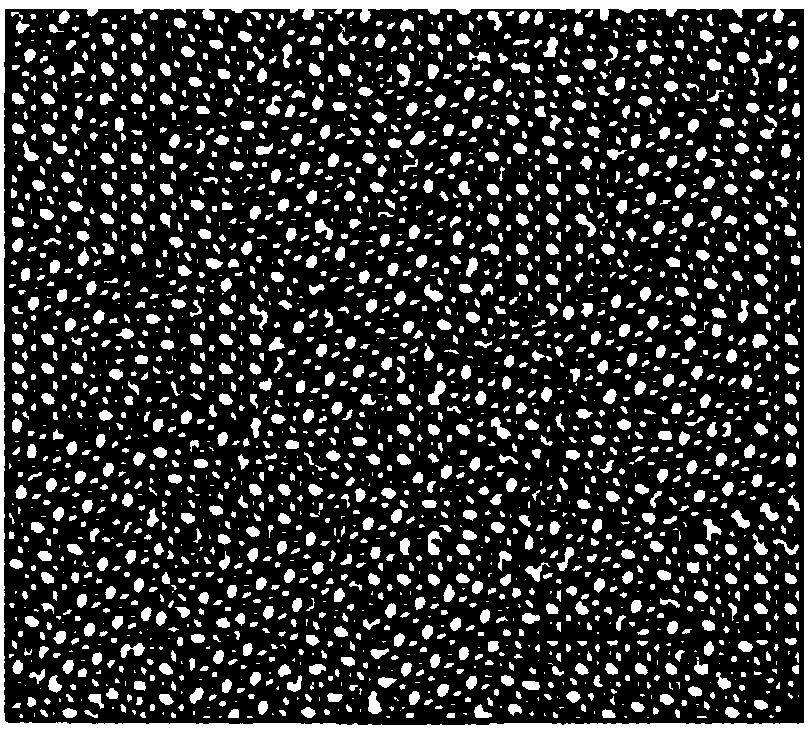

[0029] The upper and lower surfaces of the EVA film are independently pressed with a mixed pattern with periodic arrangements of square pyramid patterns and frosted patterns; among them, the periodic length of the upper surface pattern is 393mm, the length of the square pyramid pattern is 193mm, and the length of the frosted pattern is 200mm ; The period length of the pattern on the lower surface is 440mm, the length of the square pyramid pattern is 200mm, and the length of the frosted pattern is 240mm.

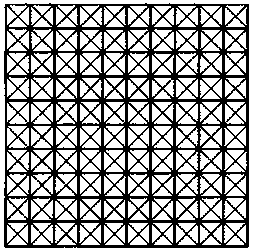

[0030] figure 1 The sectional view of the overall structure of the EVA adhesive film prepared in Example 1, the marks in the accompanying drawings are described as follows: 1-1 adhesive film layer, 1-2 frosted pattern, 1-3 quadrangular pyramid pattern; figure 2 is the front view of the frosted pattern; image 3 It is the front view of the quadrangular pyramid pattern.

[0031] Production lines No. 1 to No. 3 were used to prepare EVA films under the conditions of production...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com