Special cup holder adopting hydraulic drive based precise clamping for motor vehicle

A technology for motor vehicles and special cups, applied in vehicle parts, special positions of vehicles, optical aspects of lighting equipment, etc., can solve problems such as unstable fixing of cups, and achieve the effect of wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

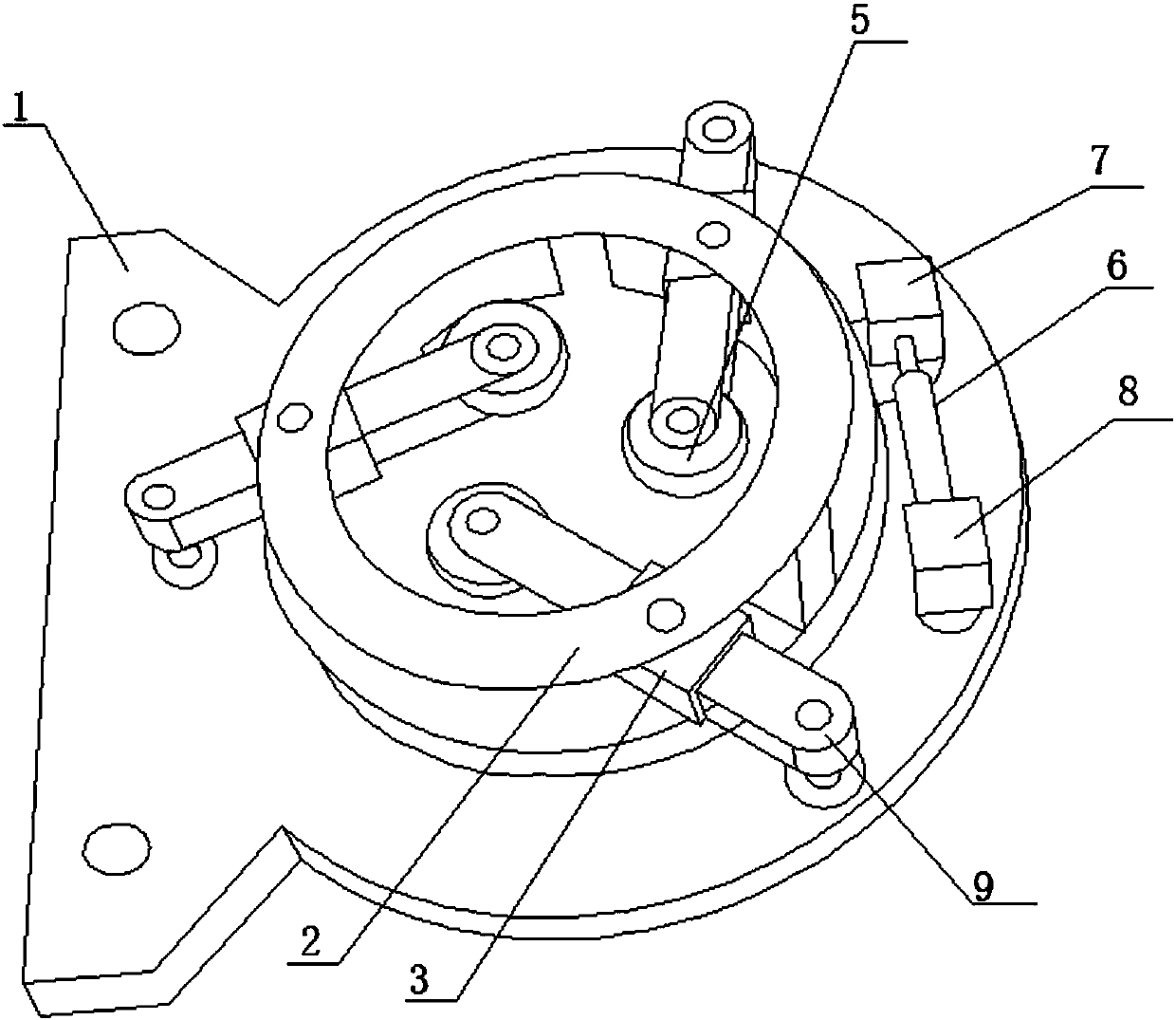

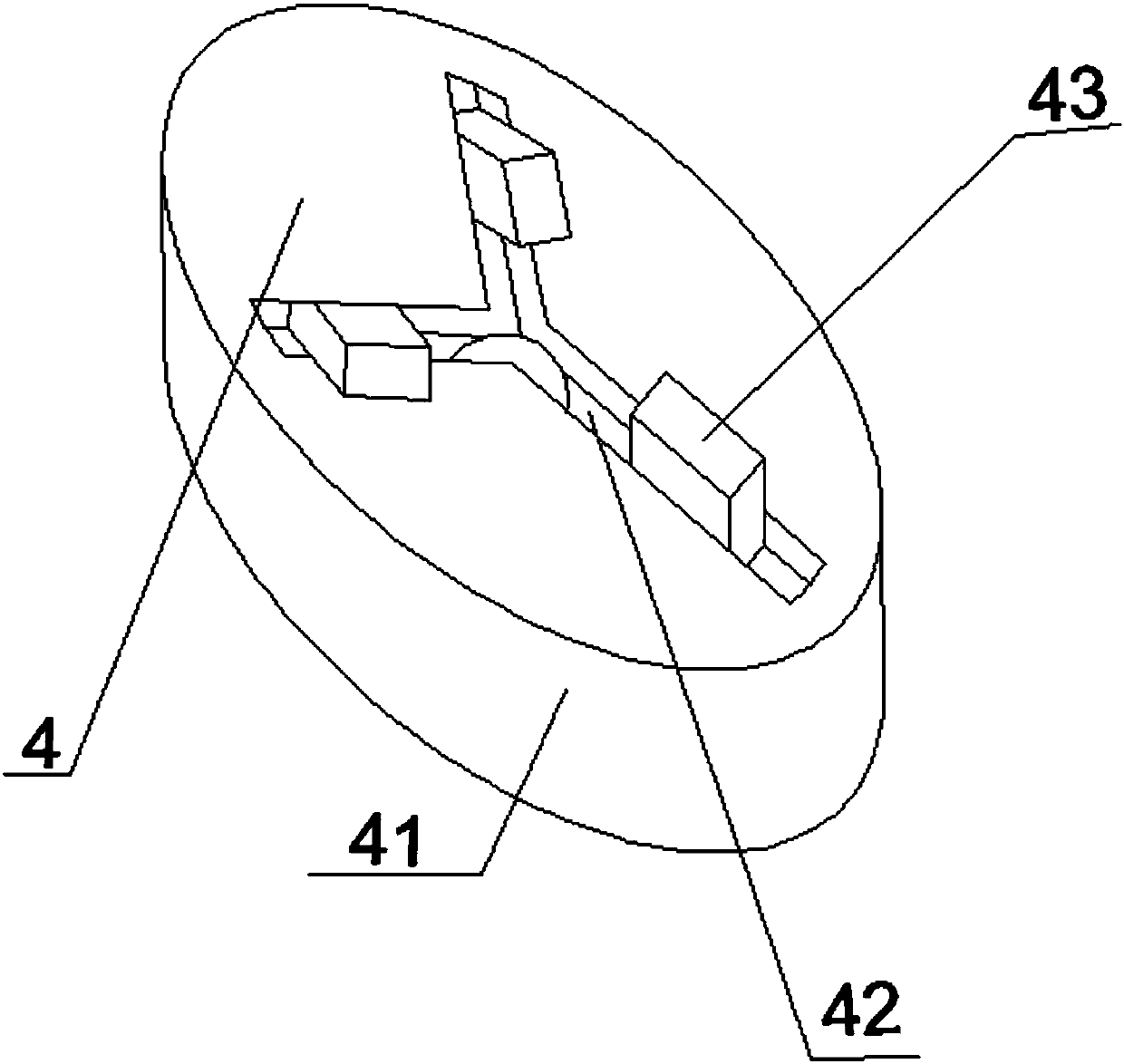

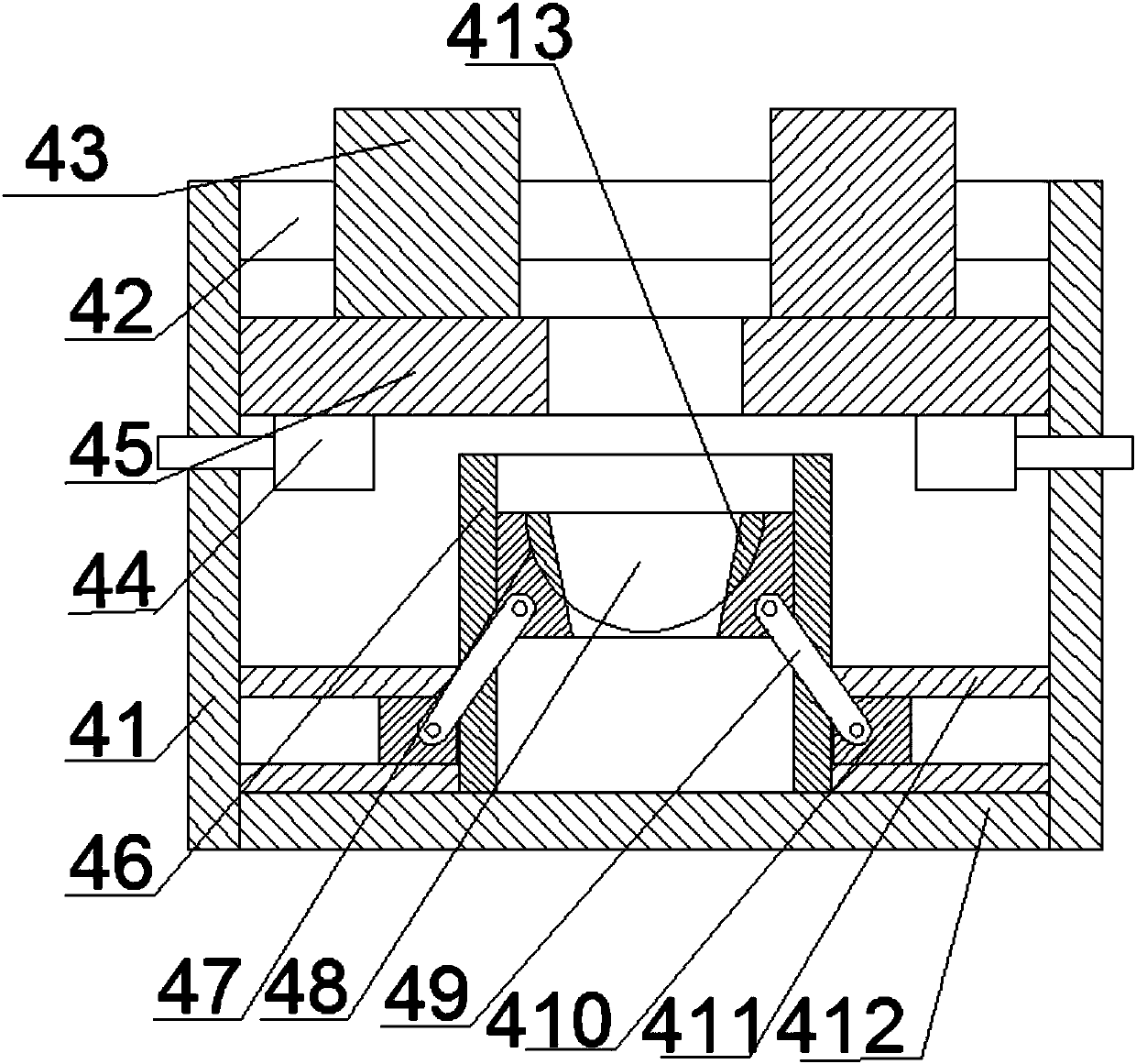

[0033] A special cup holder for motor vehicles that is accurately clamped by hydraulic drive, including a mounting seat, the mounting seat is provided with a cup holder, the cup holder is a hollow cylinder in the middle, and the cup holder can rotate along the circumference of the cup holder , the outer cylindrical surface of the cup holder is uniformly provided with 3 grooves, the inner surface of the upper side of the groove is also hinged with three hollow moving blocks, and the mounting seat is also hinged with three connecting rods, and the other end of the connecting rods is connected with a fixed mechanism, the connecting rod passes through the hollow moving block in the groove, and the connecting rod can slide along the length direction of the connecting rod in the hollow moving block. Through this setting, put the cup into the cup holder first, and then rotate the cup holder. When the cup holder rotates, it drives the hollow moving block to rotate. The hollow moving bl...

Embodiment 2

[0035] On the basis of Embodiment 1, a connection block 1 is also connected to the cup holder, a square block 1 is hinged on the connection block 1, and a connection block 2 is also arranged on the mounting base. The second is hinged with a square block two, and is also provided with a driving hydraulic cylinder and a controller. The driving hydraulic cylinder is electrically connected to the controller. The driving hydraulic cylinder includes a fixed end and a moving end, and the fixed end is connected to the square block two. , the mobile end is connected to square block one. Through this arrangement, the extension of the moving end of the drive hydraulic cylinder pushes the connection block to rotate, and the rotation of the connection block simultaneously drives the cup holder to rotate. Control the extension length of the moving end of the driving hydraulic cylinder by the controller to control the rotation range of the cup holder, thereby more accurately fixing the cup a...

Embodiment 3

[0037] On the basis of the above embodiments, the fixing mechanism is a circular wheel. Through this setting, the contact area between the fixing mechanism and the cup is larger, and the fixing of the cup is more stable, which solves the problem of unstable fixing of the cup by the existing equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com