Mortar mixing mechanism for dry-mixed mortar

A dry-mixed mortar and slurry mixing technology, which is applied to clay preparation devices, chemical instruments and methods, cement mixing devices, etc., can solve the problems of local solidification, waste of resources, safety and other problems, so as to prevent local solidification, avoid waste of resources, Not easy to shift effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

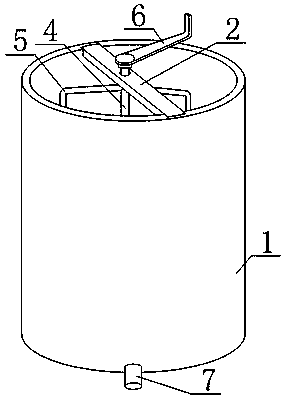

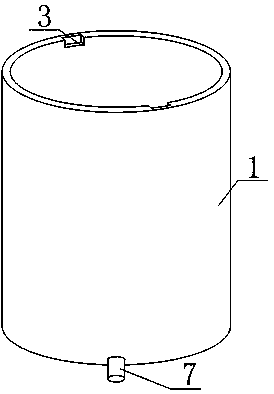

[0017] Such as figure 1 , figure 2 and image 3 As shown, the mechanism for mixing dry-mixed mortar includes a cylinder 1, a supporting plate 2 and a mixing device, wherein the lower end of the cylinder 1 is sealed, and the top of the inner side wall of the cylinder 1 is formed with two positioning notches 3, two The two positioning notches 3 are respectively located on opposite sides of the side wall of the cylinder 1, the two ends of the support plate 2 are respectively embedded in the two positioning notches 3, and the central part of the support plate 2 is formed with a through hole penetrating the upper and lower end surfaces. In order to facilitate the discharging, the side wall of the cylinder 1 is provided with a discharge pipe 7 connected to the inside of the cylinder 1, and the discharge pipe 7 is preferably close to the bottom end of the cylinder 1.

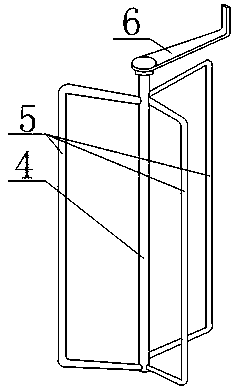

[0018] The mixing device includes a central mixing shaft 4, an operating rod 6 and a frame mixing frame 5. The central...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com