Low-temperature top-mounted ball valve seat structure and on-line maintenance disassembly method thereof

A valve seat and installation technology, which is applied in the direction of valve devices, cocks including cutting devices, mechanical equipment, etc., can solve the problems of time-consuming and labor-intensive rotation and tightening of the nut 4, affecting online maintenance work, and large working load of the spring 6, etc., to achieve Reduce energy consumption, improve work efficiency, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

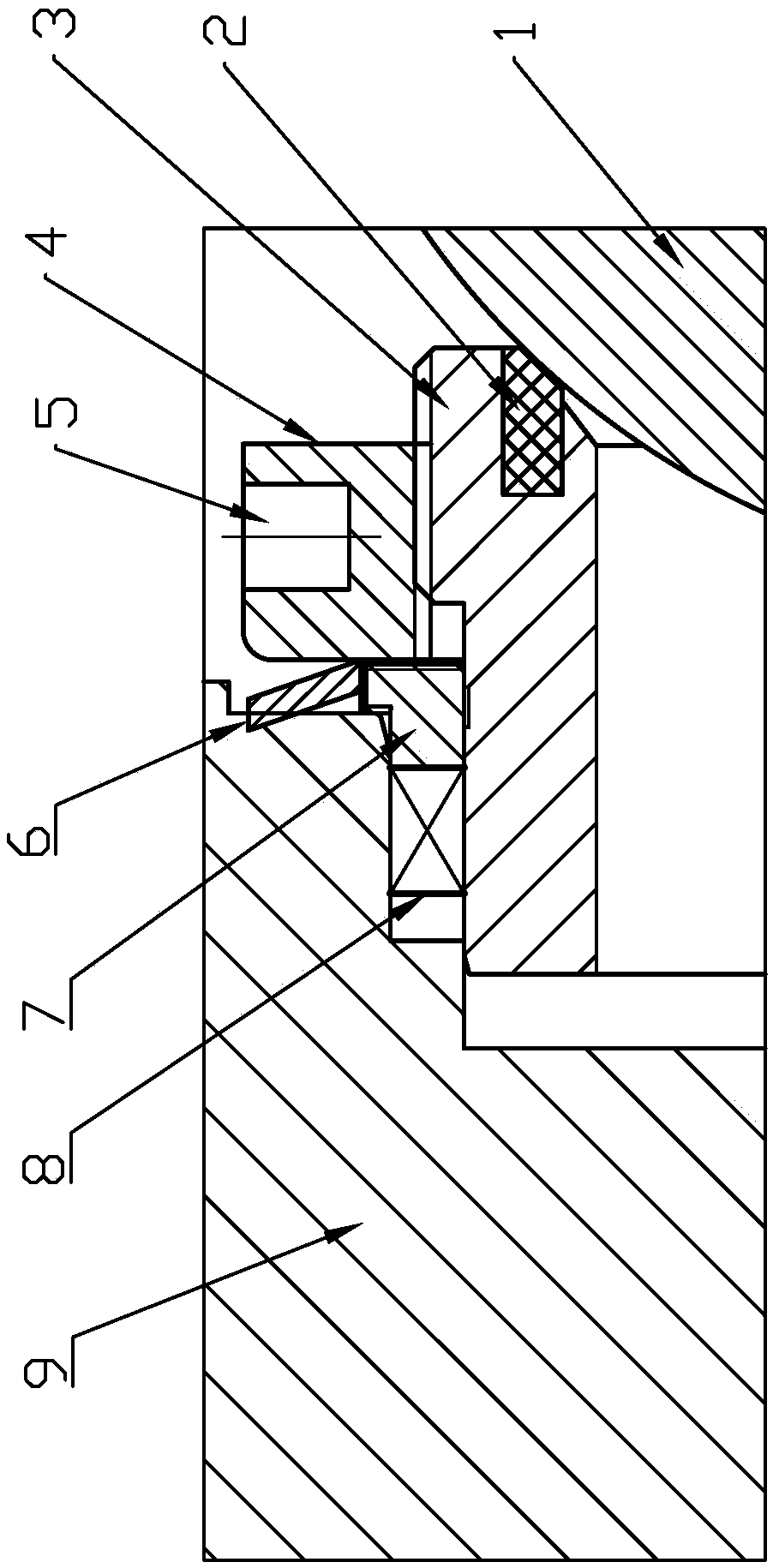

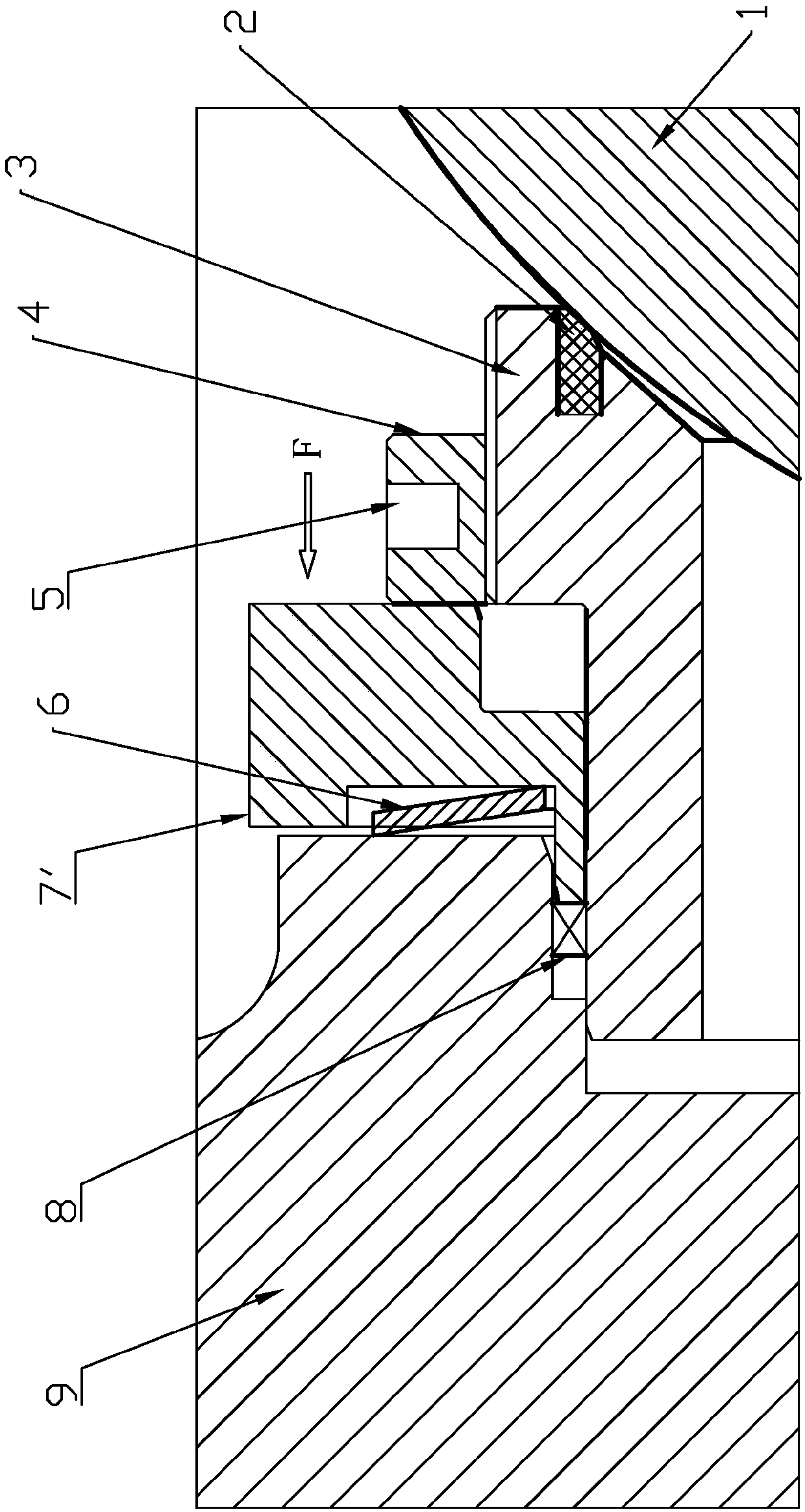

[0024] Such as figure 2 As shown, the present invention provides a low-temperature top-entry ball valve seat structure, which consists of a valve body 9, a ball 1, a seat assembly (including a seat metal ring 3, a seat sealing ring 2), a parallel nut 4, and a spring seat 7 ', spring 6, lip seal 8, wherein:

[0025] One end of the valve seat metal ring 3 extends into the valve body 9, and the other end forms a sealed connection with the ball 1 through the valve seat sealing ring 2;

[0026] The lip seal ring 8 is filled in the gap formed between the valve seat metal ring 3 and the valve body 9, and forms a sealed connection with the valve body 9;

[0027] The parallel nut 4 is threadedly connected to the outer side of the valve seat metal ring 3; a certain number of blind holes are opened around the parallel nut 4;

[0028] The spring seat 7' is sleeved outside the valve seat metal ring 3, and is located between the valve body 9 and the tightening nut 4, and its inner side e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com