Robot and large-torque rotatable joint power device thereof

A power device, rotary technology, applied in the field of robots, to achieve power saving, energy saving and low pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

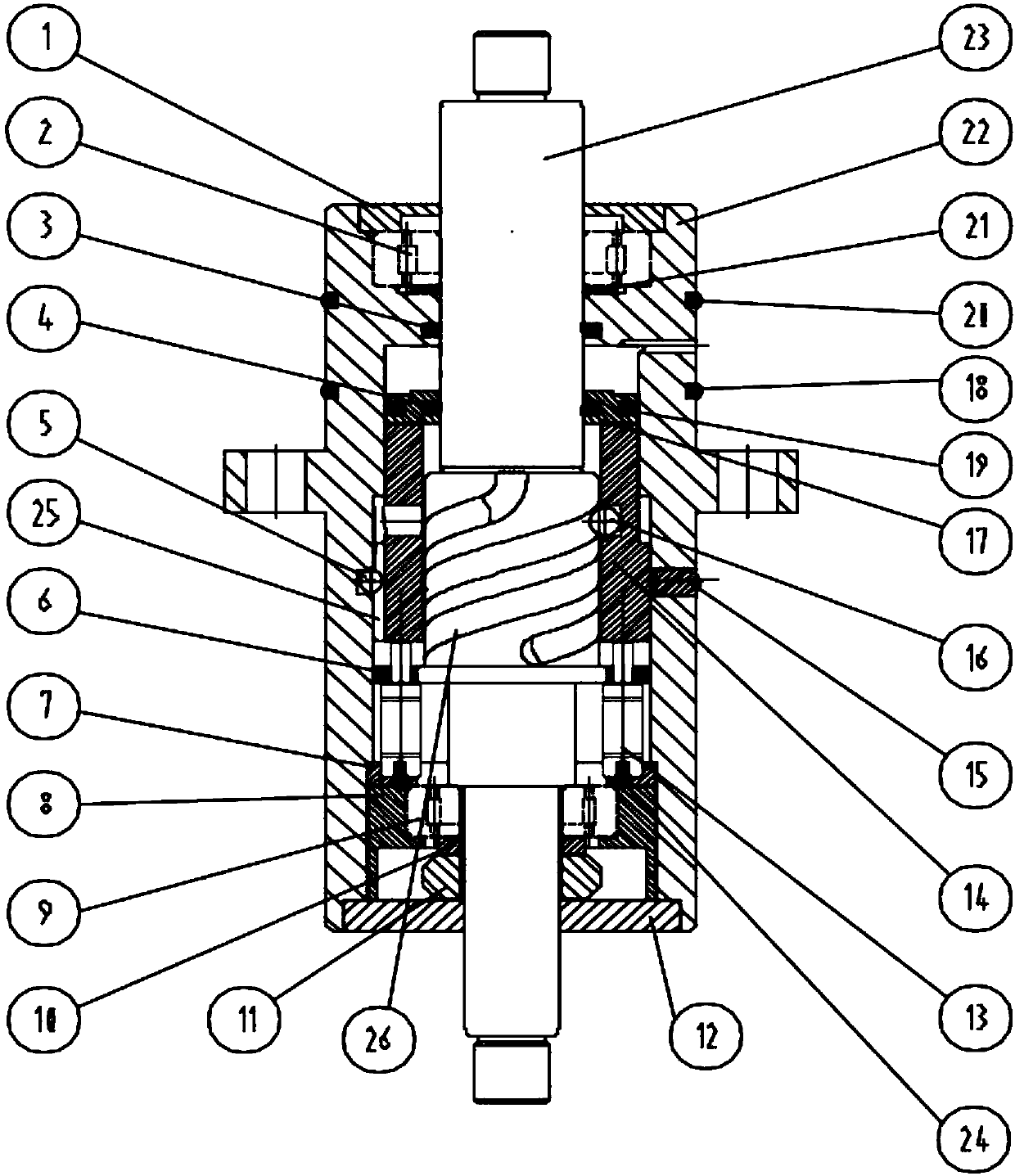

[0031] A kind of robot, its joint part adopts a kind of high-torque rotatable joint power device, and described high-torque rotatable joint power device includes reciprocating piston 17, the guide piece 14 that is connected with piston 17, set on the end of piston The active power system includes a liquid injection hole and a closed hydraulic chamber, the hydraulic chamber and the liquid injection hole are connected to an external hydraulic power system, and the reset power system provided at the end of the guide includes a nitrogen spring 13;

[0032] The guide piece 14 is connected with the piston rod 23, and the axial reciprocating motion of the guide piece 14 is converted into the radial rotation of the piston rod 23: the guide piece 14 is embedded with a guide steel ball 16; The guide steel ball matches the Gothic-style guide groove 26; the reciprocating motion of the guide member 14 drives the guide steel ball 16 to move along the Gothic-style steel ball groove 26, and th...

Embodiment 2

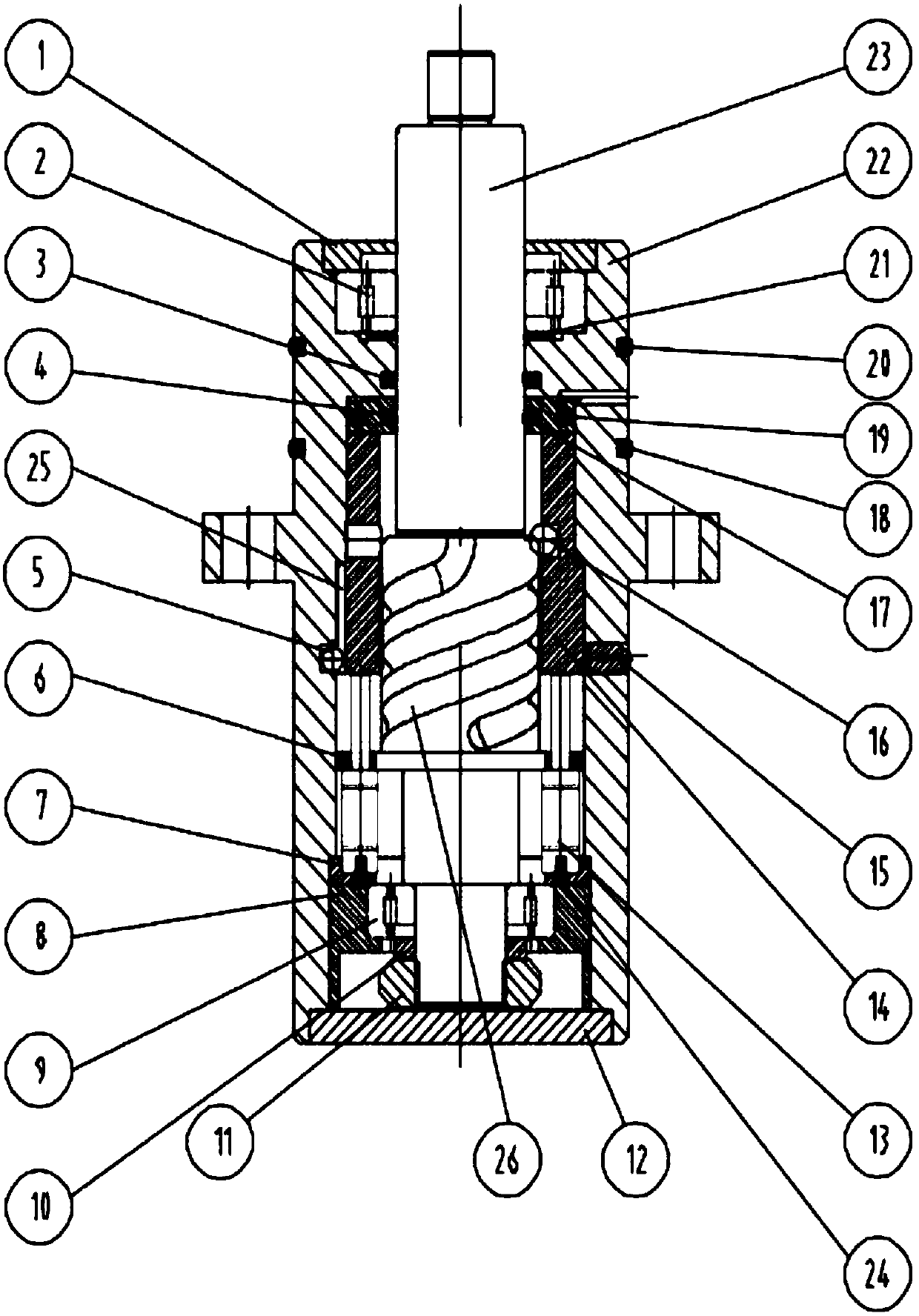

[0036] A kind of robot, its joint part adopts a kind of high-torque rotatable joint power device, and described high-torque rotatable joint power device includes reciprocating piston 17, the guide piece 14 that is connected with piston 17, set on the end of piston The active power system includes an air injection hole and a closed air pressure chamber, the air pressure chamber and the air injection hole are connected to an external air pressure power system, and the reset power system provided at the end of the guide includes a nitrogen spring 13;

[0037] The guide piece 14 is connected with the piston rod 23, and the axial reciprocating motion of the guide piece 14 is converted into the radial rotation of the piston rod 23: the guide piece 14 is embedded with a guide steel ball 16; The guide steel ball matches the Gothic-style guide groove 26; the reciprocating motion of the guide member 14 drives the guide steel ball 16 to move along the Gothic-style steel ball groove 26, an...

Embodiment 3

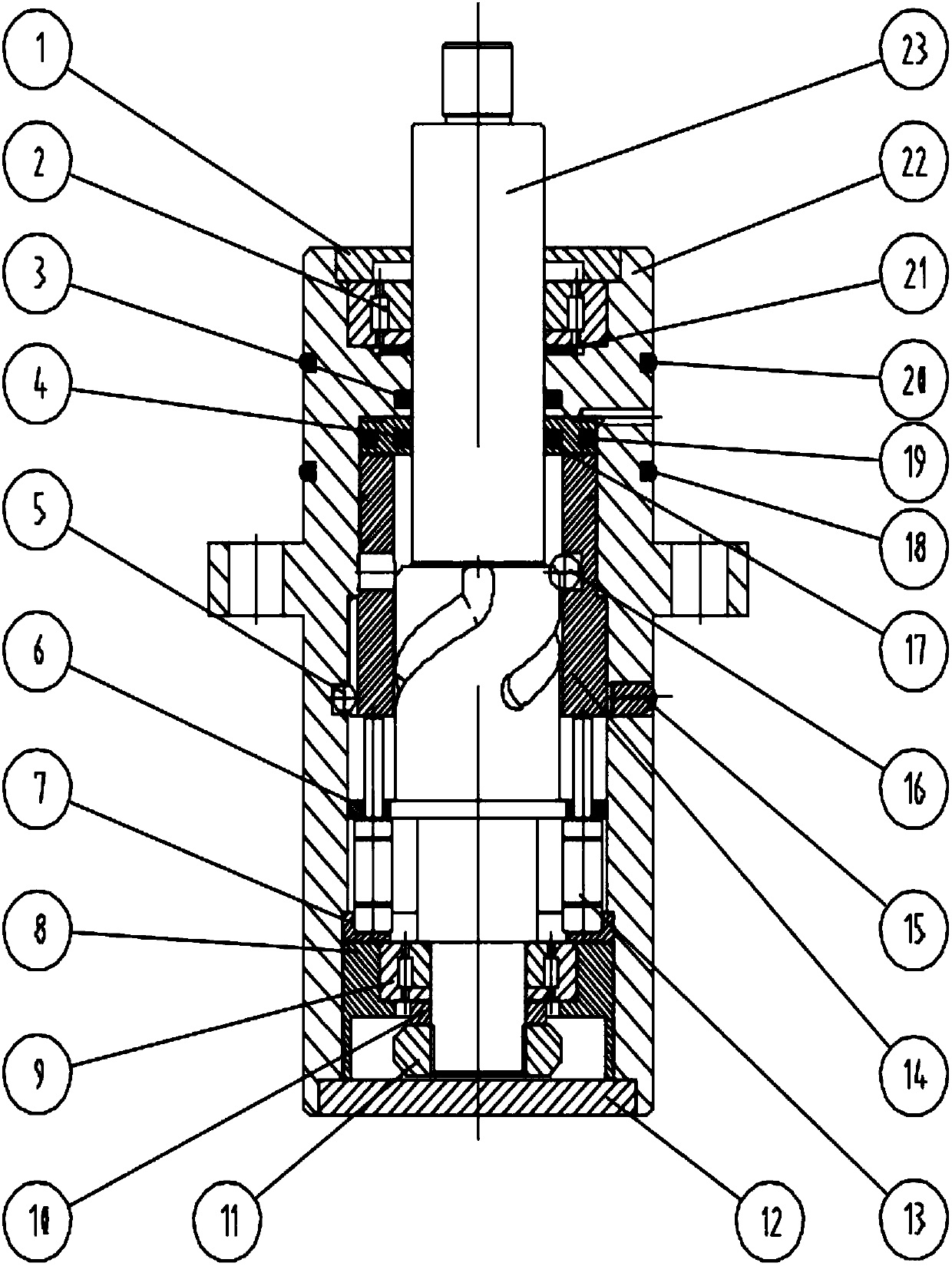

[0041] A kind of robot, its joint part adopts a kind of high-torque rotatable joint power device, described Gothic guide groove 26 is one, can realize 180 degree rotation. Other components are basically the same as in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com