Laser cleaning equipment

A technology of laser cleaning and equipment, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of low degree of automation, low cleaning and processing efficiency, unable to achieve efficient automatic cleaning, etc., to achieve enhanced applicability, processing Efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The description of the exemplary embodiments is for the purpose of illustration only, and in no way limits the invention and its application or usage.

[0028] According to the deficiencies of the prior art and the market demand, the present invention provides a large-scale high-efficiency and energy-saving laser cleaning equipment for regenerating metal materials, thereby solving the cleaning problem of oil stains, rust layers and other pollutants on large-scale metal materials , The surface of the cleaned metal material has the effect of regeneration, thus realizing the effect of high-efficiency, green, environmental protection and energy-saving laser cleaning.

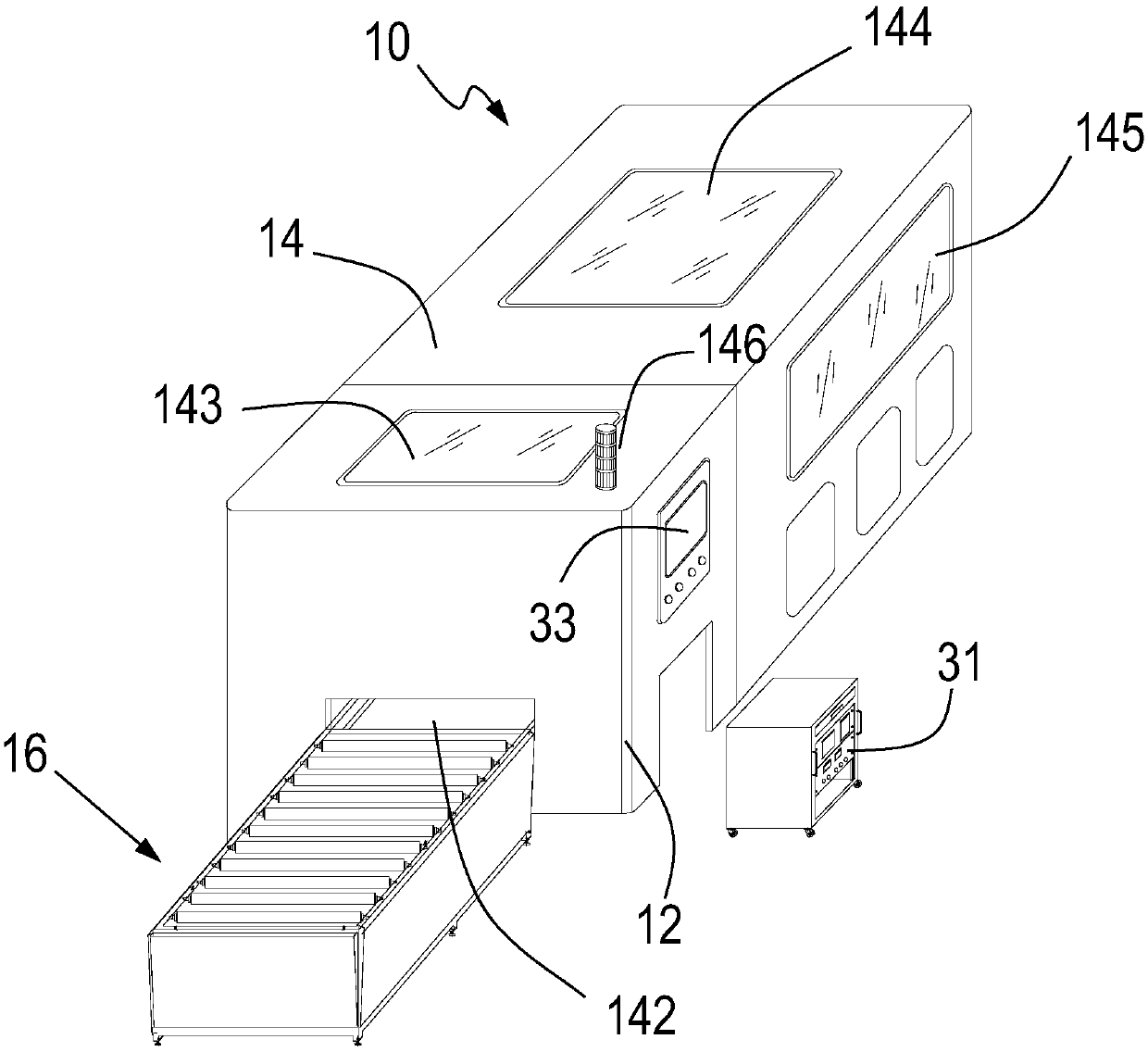

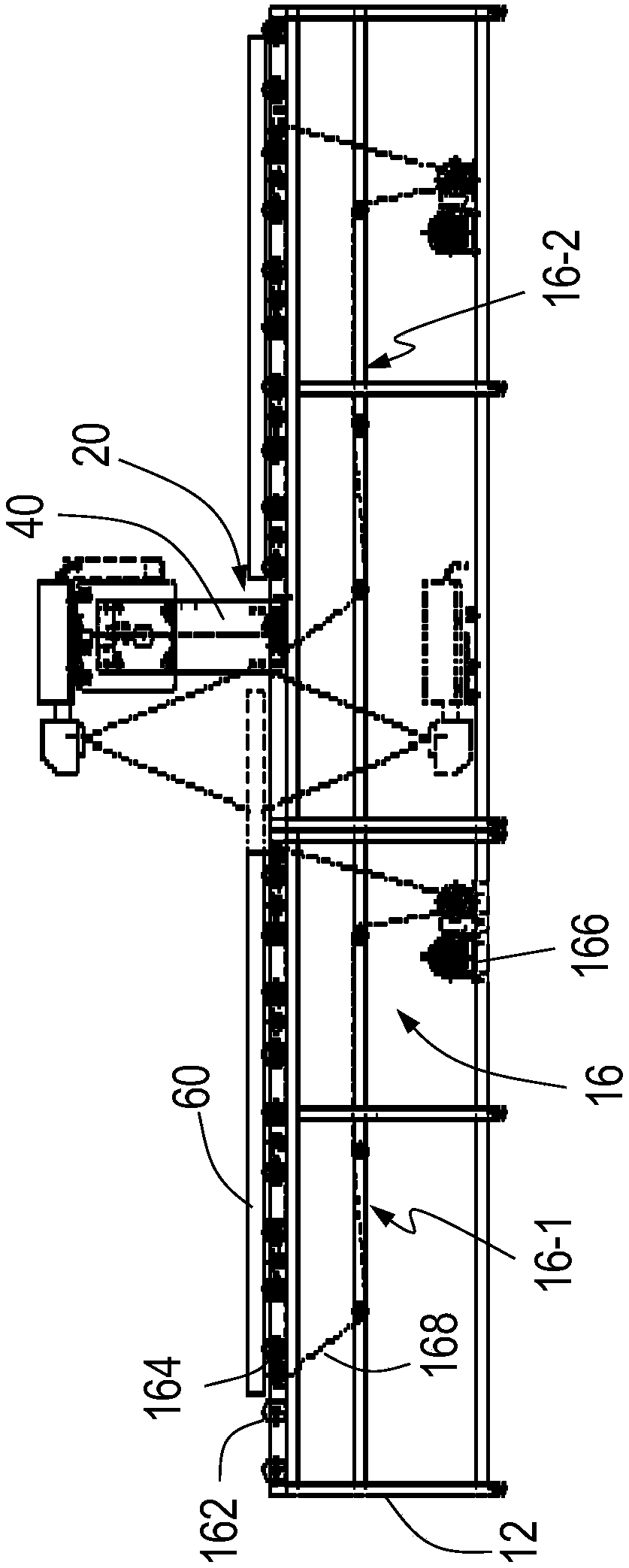

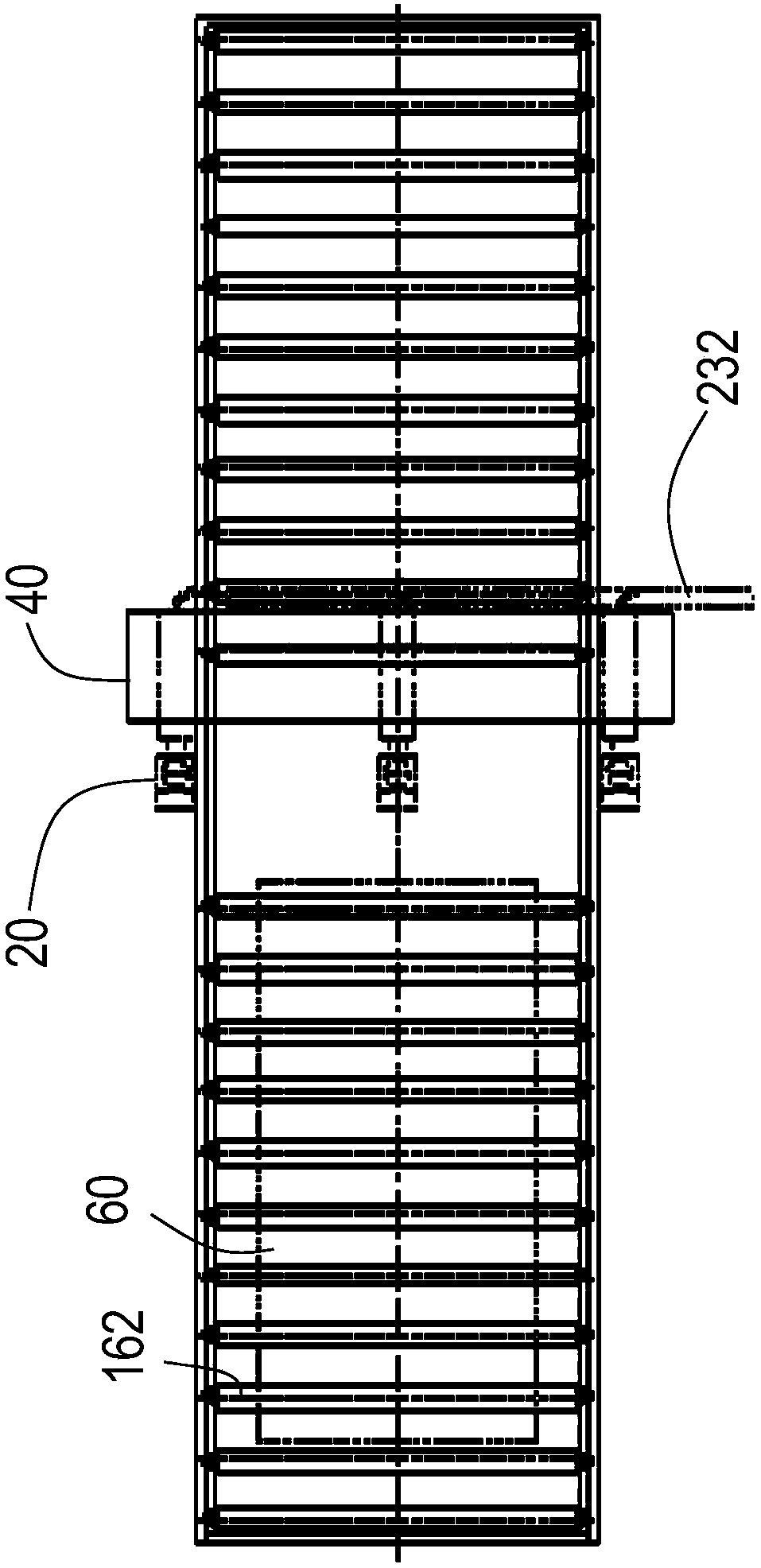

[0029] figure 1 A schematic perspective view of a laser cleaning device according to the present invention is shown. The laser cleaning equipment 10 according to the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com