Method and device for testing tensile force of welding point of cover cap of lithium battery

A technology of tensile testing and lithium batteries, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as the inability to quickly detect unqualified welding firmness, achieve the effect of improving quality and efficiency, and minimizing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

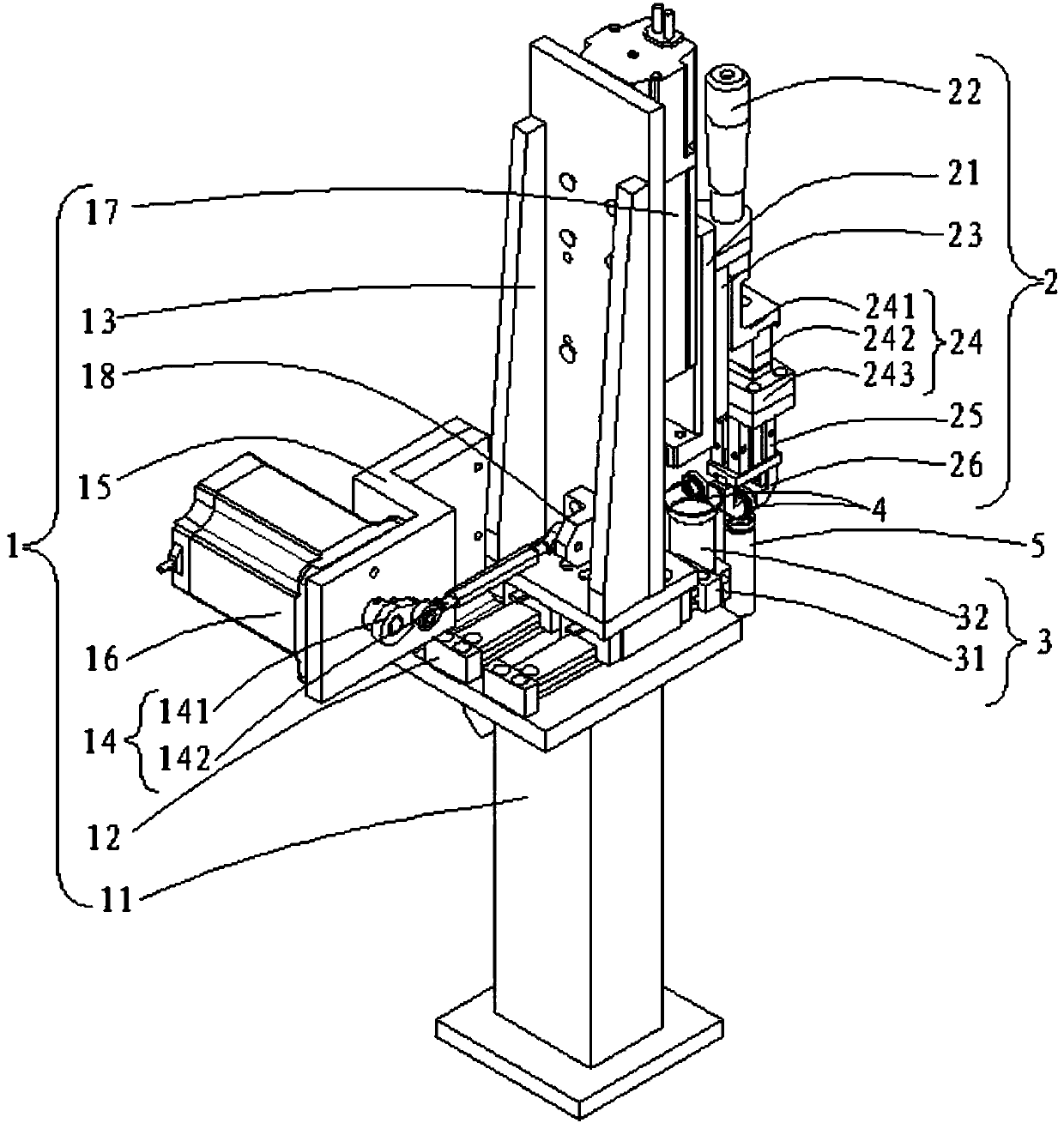

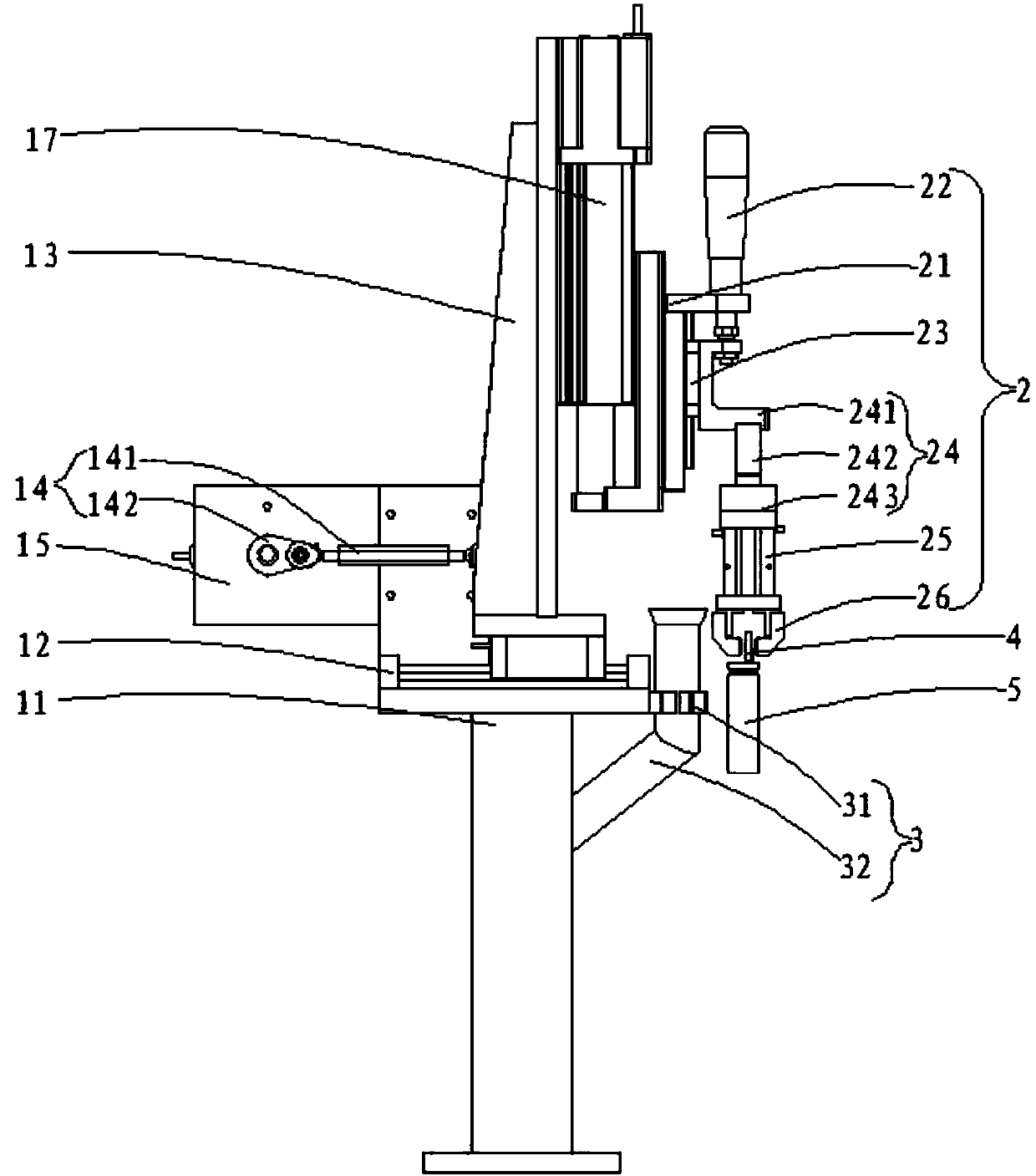

[0046] refer to Figure 1 to Figure 5 , the present invention is a kind of tensile testing device of cap solder joint of lithium battery, comprises platform mechanism 1, the tension mechanism 2 that is arranged on the platform mechanism 1 and the unqualified cap discharging mechanism 3 that is arranged on the platform mechanism 1;

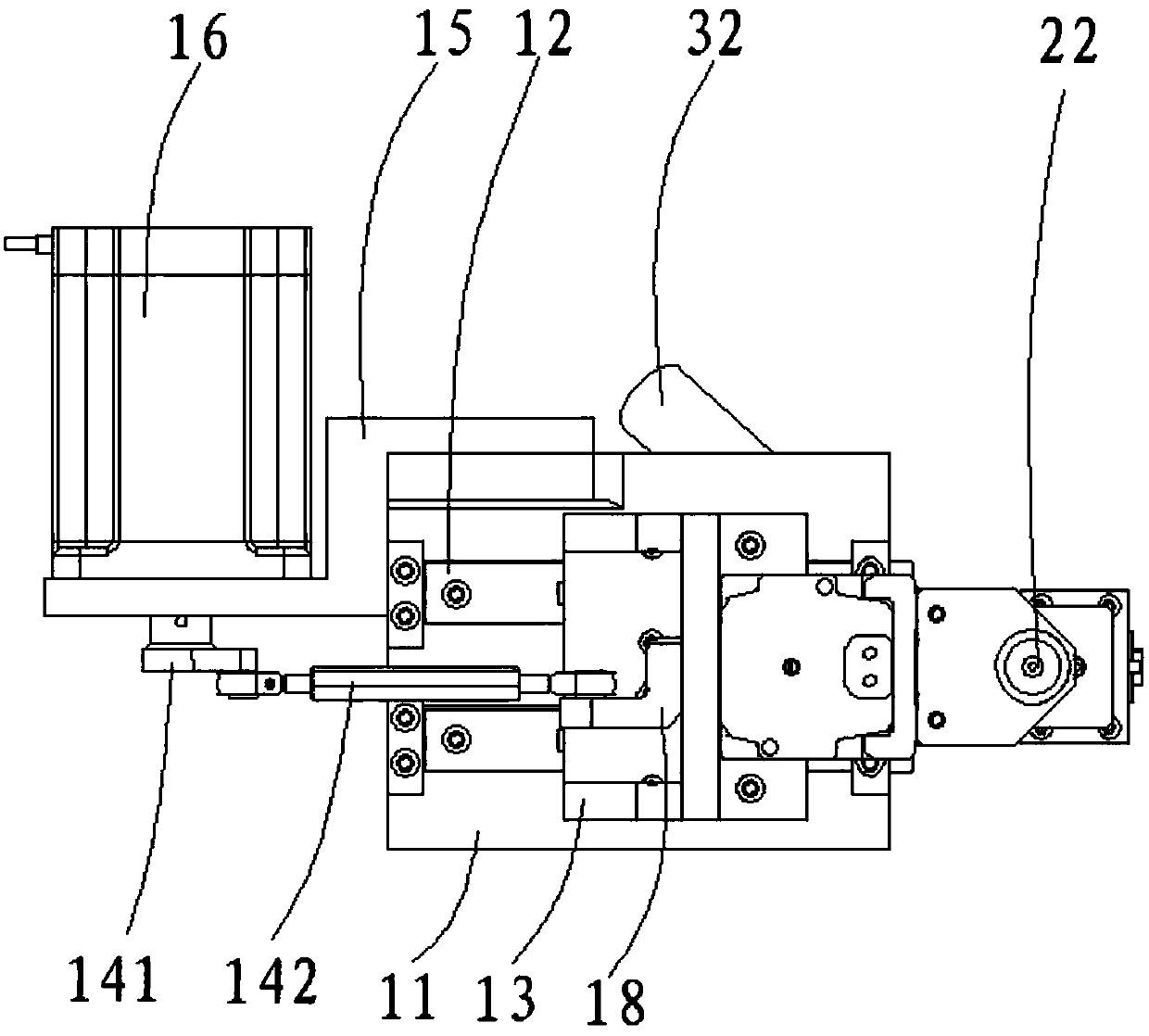

[0047] The platform mechanism 1 in the present invention comprises a main frame 11, a transverse rail assembly 12 arranged on the upper end of the main frame 11, a secondary frame 13 arranged on the lateral rail assembly 12, and a connecting block 18 connected to one side of the secondary frame 13. The transmission assembly 14 , the power component 16 connected with the transmission assembly 14 and the electric cylinder 17 arranged on the upper end of the secondary frame 13 , the power component 16 is arranged on the main frame 11 through the fixing plate 15 .

[0048] Preferably, the tension mechanism 2 includes a fixed bracket 21 connected to the...

Embodiment 2

[0055] The transmission assembly 14 includes a driving link connected to the power component 16 and a transmission link 142 connected to the driving link. One end of the driving link 142 is connected to the driving link, and the other end is connected to the connection block 18 . When the pulling force is judged to be unqualified, the power part 16 drives the active connecting rod to rotate to the reverse limit position, and then resets.

[0056] Preferably, adjust the stroke and speed of the electric cylinder 17 and the pulling force of the tension regulator 22 according to the pulling force of the tabs of the lithium battery 5 and the welding of the cap 4, by judging the pulling force value of the pulling force sensor 242 or the stroke range of the electric cylinder 17 To determine whether the welding of the tab and the cap 4 is good.

[0057] The specific steps of the tension test method of the lithium battery cap solder joint of the present invention are as follows:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com