A kind of hygroscopic antibacterial 3D nanofiber medical dressing and preparation method thereof

A nanofiber, 3D technology, applied in absorbent pads, medical science, bandages, etc., can solve the problems of poor controllability of porosity and mechanical properties of fiber films, difficult to meet medical dressings, etc., and is conducive to wound healing and wound maintenance. Wetting, reducing the effect of springback stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

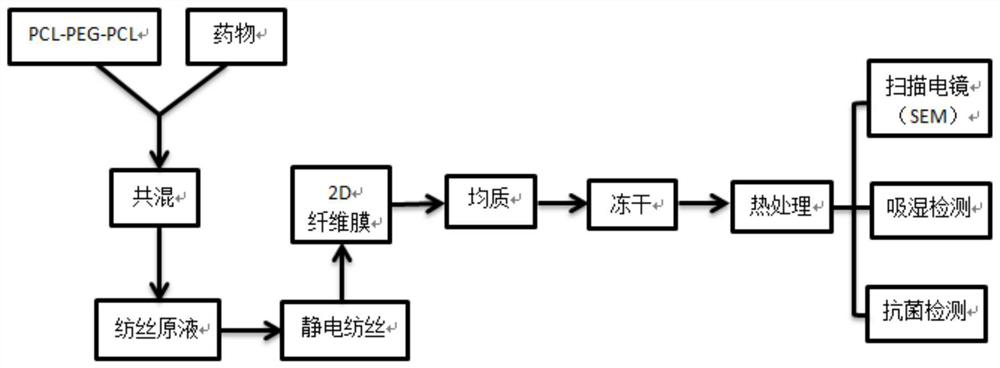

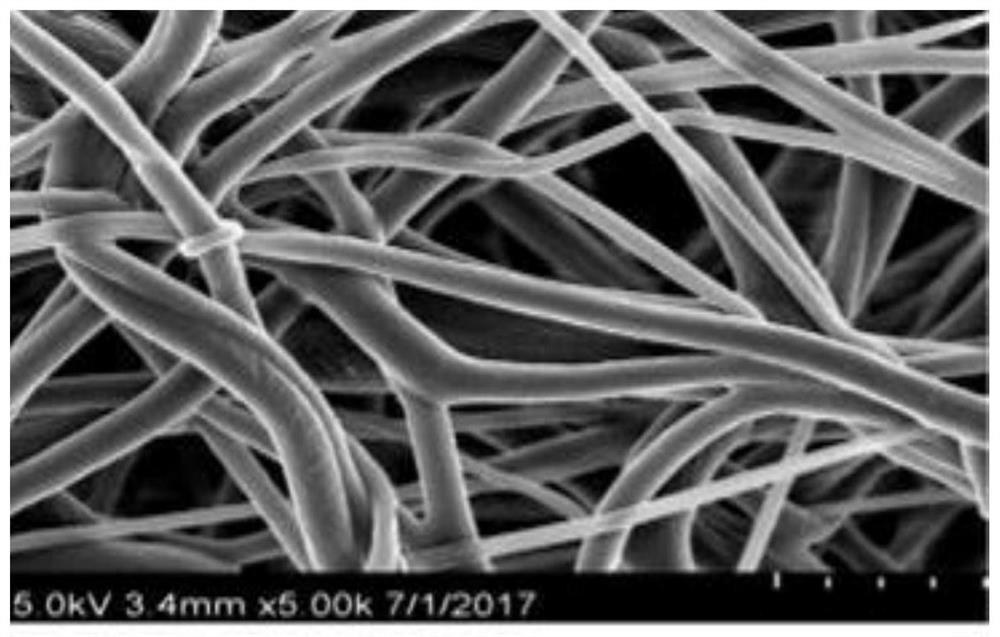

[0042] (1) Dissolve amoxicillin at 20 mg / mL in a mixed solution of acetone and N,N-dimethylformamide (wt / wt, 1 / 1), then dissolve PCL-PEG-PCL in a mixed solution of amoxicillin The mixed solution of moxicillin was fully dissolved at 25° C., and a spinning solution with a mass fraction of 25% PCL-PEG-PCL was prepared. The spinning solution was transferred to a 10mL syringe, the spinning voltage was 15kV, the spinning speed was 0.5mL / h, and the receiving distance was 12cm for spinning, and the drum collected the PCL-PEG-PCL nanofiber 2D film.

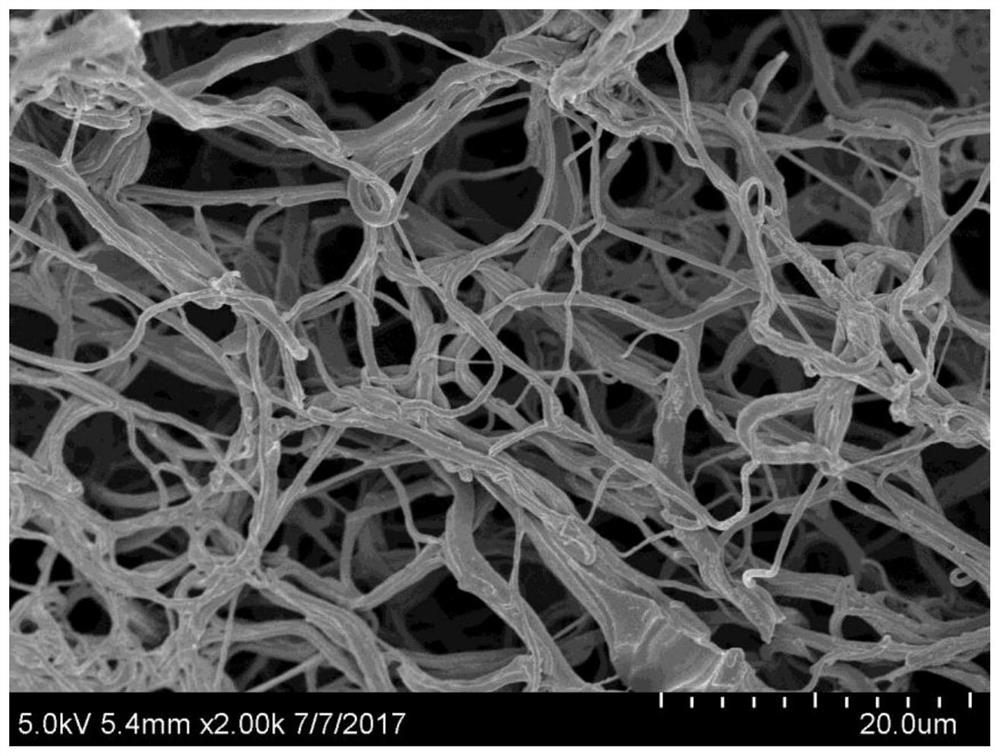

[0043] (2) Accurately weigh 15.429g of PCL-PEG-PCL nanofiber membrane, place it in a 500mL beaker, add a certain amount of distilled water, prepare a homogeneous solution with a concentration of 40mg / ml, and homogenize it at 15krpm 10min. 370mL nanofiber homogeneous solution was placed in a sealed container, cooled with liquid nitrogen for 15min, and vacuum-dried with a freeze dryer for 24h. The freeze-dried sample was placed in a glass ...

Embodiment 2

[0045] (1) Dissolve amoxicillin and vancomycin hydrochloride at 0.1 mg / ml in a mixed solution of acetone and N,N-dimethylformamide (wt / wt, 0.1 / 10), then PCL-PEG- PCL was dissolved in a mixed solution mixed with amoxicillin, fully dissolved at 30° C., and a spinning solution with a mass fraction of 15% PCL-PEG-PCL was prepared. The spinning solution was transferred to a 10mL syringe, the spinning voltage was 5kV, the spinning speed was 0.1mL, and the receiving distance was 5cm, and the PCL-PEG-PCL nanofiber 2D film was collected by the roller.

[0046] (2) Accurately weigh 15.429g of PCL-PEG-PCL nanofiber membrane, place it in a 500mL beaker, add a certain amount of tert-butanol, prepare a homogeneous solution with a concentration of 5mg / ml, and prepare it under the condition of 6krpm Homogenization for 12min. 370mL nanofiber homogeneous solution was placed in a sealed container, placed in a -10°C environment for 5min, and vacuum-dried with a freeze dryer for 12h. The freeze-...

Embodiment 3

[0048] (1) Dissolve amoxicillin and penicillin at 1 mg / mL in a mixed solution of acetone and N,N-dimethylformamide (wt / wt, 10 / 0.1), then dissolve PCL-PEG-PCL in the mixed solution A mixed solution of amoxicillin was prepared, fully dissolved at 0°C, and a spinning solution with a mass fraction of 35% PCL-PEG-PCL was prepared. The spinning solution was transferred to a 10mL syringe, the spinning voltage was 40kV, the spinning speed was 5mL / h, and the receiving distance was 25cm, and the PCL-PEG-PCL nanofiber 2D film was collected by the roller.

[0049] (2) Accurately weigh 15.429g of PCL-PEG-PCL nanofiber membrane, place it in a 500mL beaker, add a certain amount of tert-butanol to prepare a homogeneous solution with a concentration of 80mg / ml, and prepare it under the condition of 15krpm Homogenize for 15min. 370mL nanofiber homogeneous solution was placed in a sealed container, placed in -20°C environment for 15min, and vacuum-dried with a freeze dryer for 48h. The freeze-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com