A bread production line and its dividing mechanism

A production line and bread technology, applied in the direction of dough cutting machinery, dough forming and cutting equipment, dough forming machinery or equipment, etc., can solve problems such as poor segmentation effect, achieve better guiding effect, good orientation, reduce wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

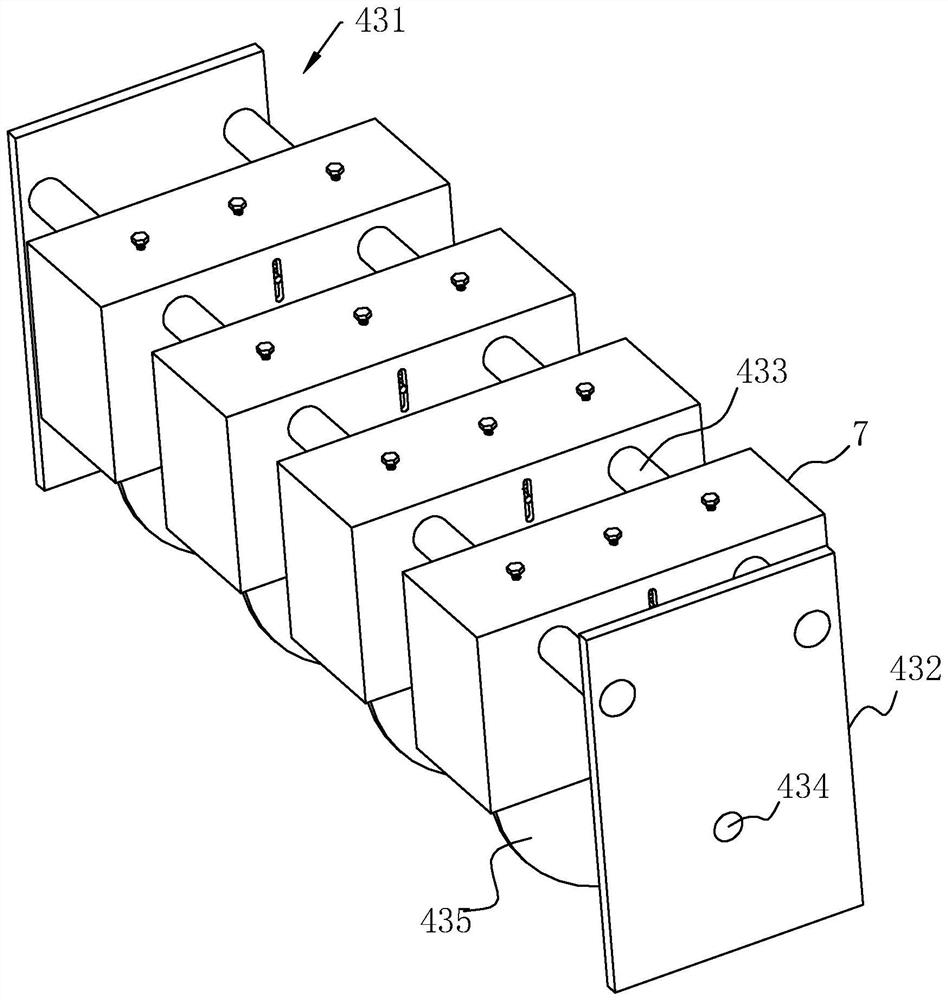

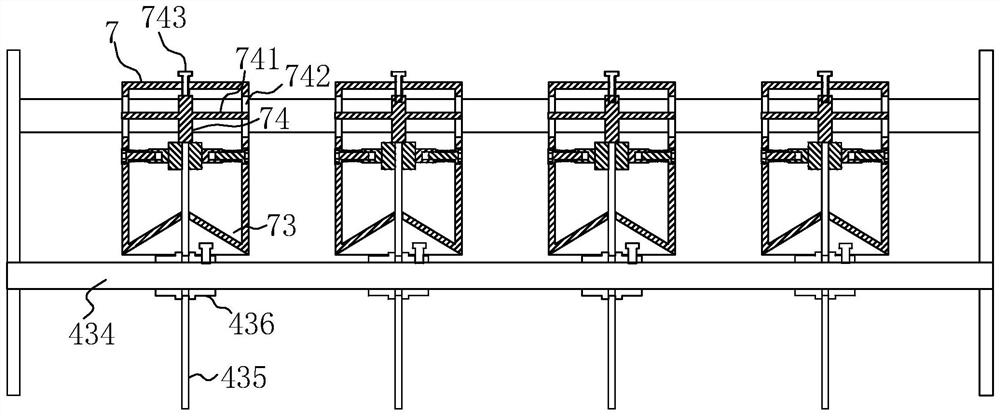

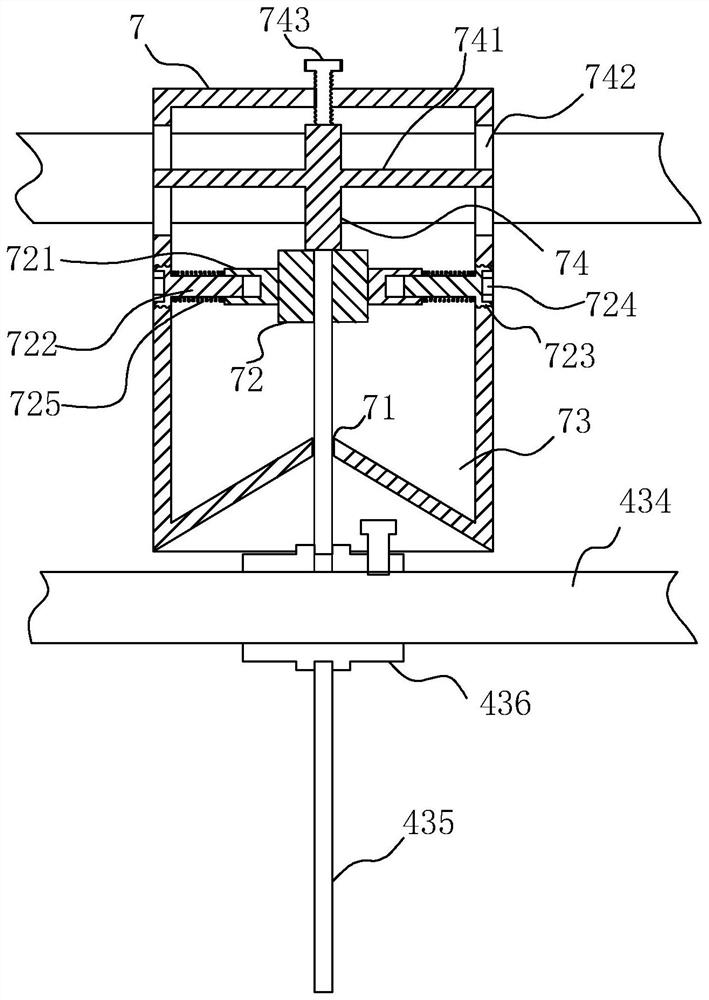

[0038] Embodiment 1: a dividing mechanism on a bread production line, such as figure 1 As shown, it includes a mounting frame 431 and a cutting knife 435. The mounting frame 431 includes mounting plates 432 on both sides and a crossbar 433 connecting the two mounting plates 432. There are also mounting shafts 434 connected between the two mounting plates 432. There are four The cutting knives 435 are sleeved on the installation shaft 434 at intervals, and the box body 7 corresponding to the cutting knife 435 is sleeved on the cross bar 433. The box body 7 is slidably connected to the cross bar 433 and fixed by screws.

[0039] Such as Figure 2-Figure 3As shown, there is a mounting portion 436 extending on both sides of the cutting knife 435, and the mounting portion 436 is fixed on the mounting shaft 434 by screws. By setting in this way, the position of the cutting knife 435 can be adjusted according to different occasions. The bottom is provided with a strip groove 71 for ...

Embodiment 2

[0041] Embodiment 2: a kind of bread production line, such as Figure 4 As shown, it includes a batching device 1, a stirring device 2, a fermenter 3, a forming device 4, a proofing box 5 and a baking oven 6 arranged in sequence, wherein the batching device 1 includes a bucket 11 and a hopper 12, and in the bucket 11 is provided with a water pipe 13 for passing water, by adding the corresponding raw materials and the ratio of raw materials in the material barrel 11; then the material barrel 11 is moved to the stirring device 2 for stirring, and the stirring device 2 includes a body 21, which is placed in the body 21 is equipped with a driving motor and a stirring rod (not shown in the figure), and the raw materials after stirring are poured into the fermenter 3 for fermentation; then the fermented ones are moved to the molding device 4, and the molding device 4 includes a frame 41 , the conveyor belt 42 and the feeding mechanism, the dividing mechanism 43, the cutting mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com