An oil drum handle installation device

A technology for installing equipment and oil drums, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of heavy repetitive labor and low labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

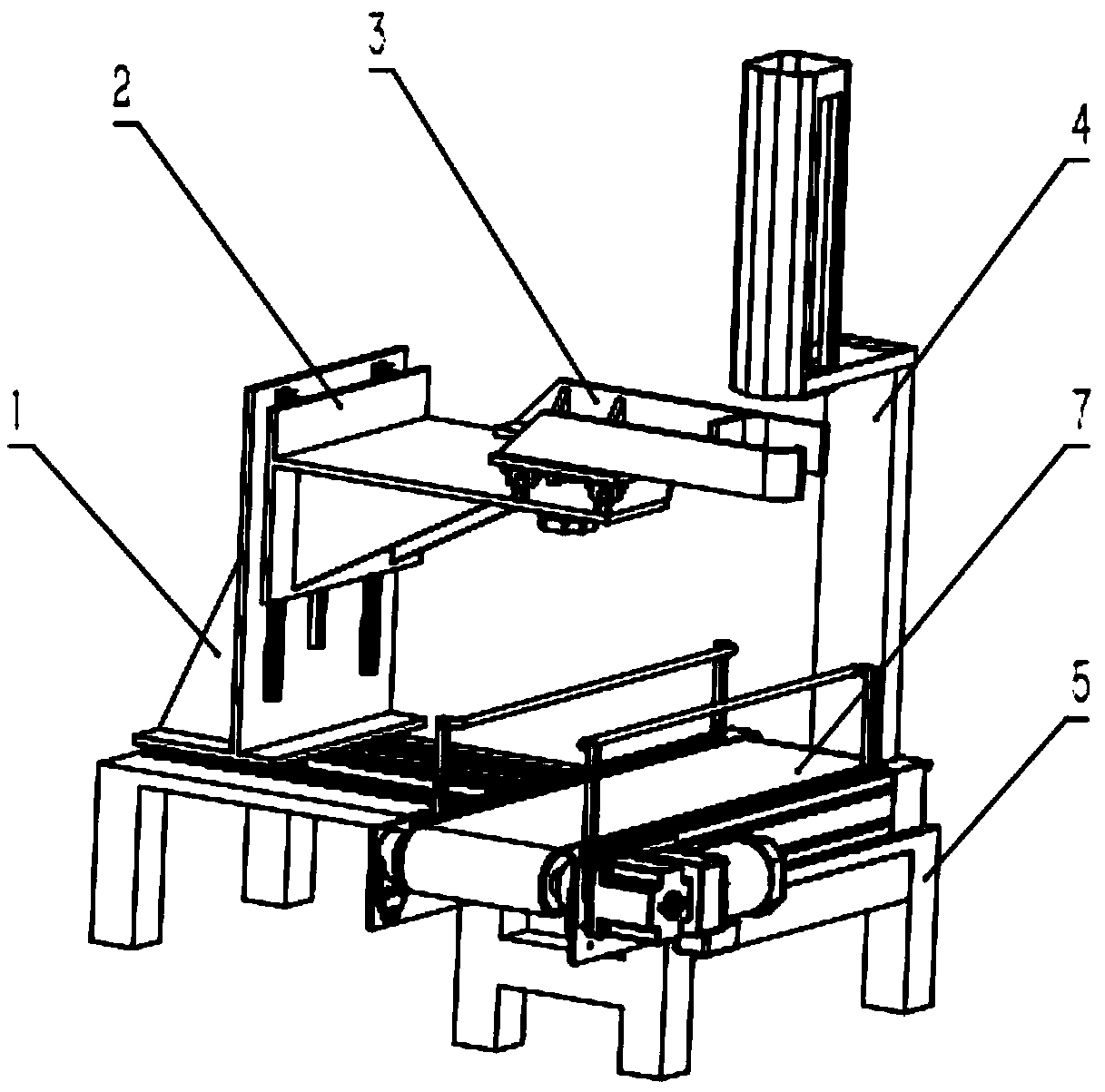

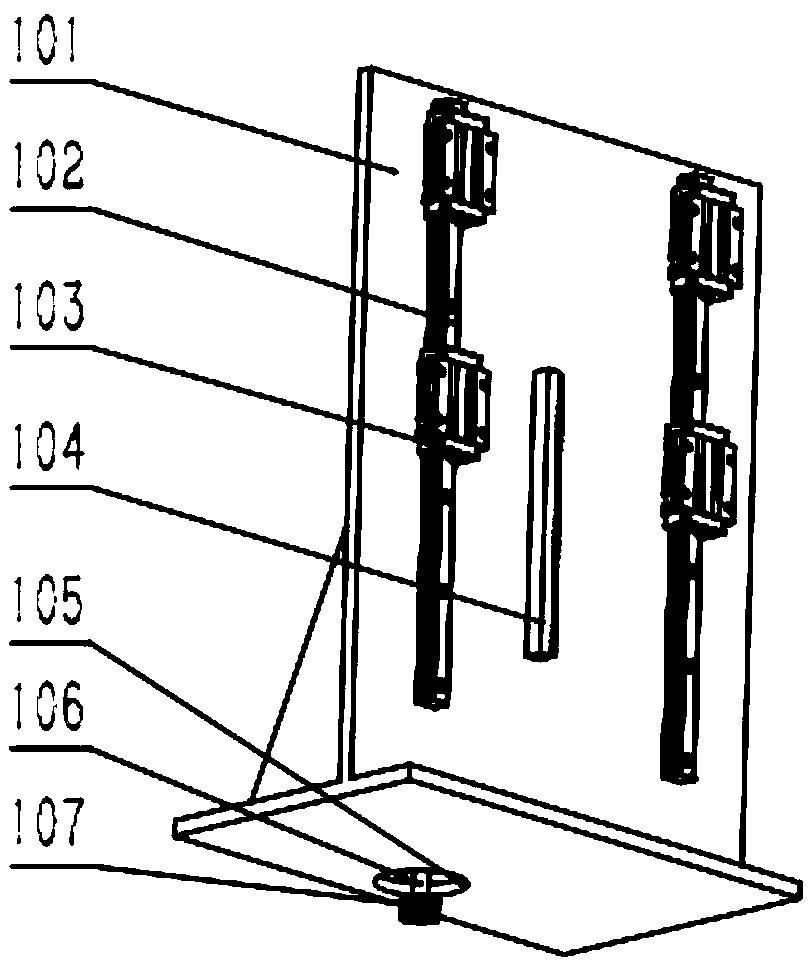

[0018] An oil drum handle installation device is composed of a Z-direction pallet assembly 1, a Y-direction pallet assembly 2, a manipulator assembly 3, an oil drum handle placement assembly 4, a base support assembly 5, and a conveyor belt assembly 7. The pallet assembly 1 is installed on the base support assembly 5, the Y-direction pallet assembly 2 is installed on the Z-direction pallet assembly 1, the manipulator assembly 3 is installed on the Y-direction pallet assembly 2, and the oil drum handle placement assembly 4 is fixed On the base support assembly 5 , the conveyor belt assembly 7 is fixed on the base support assembly 5 .

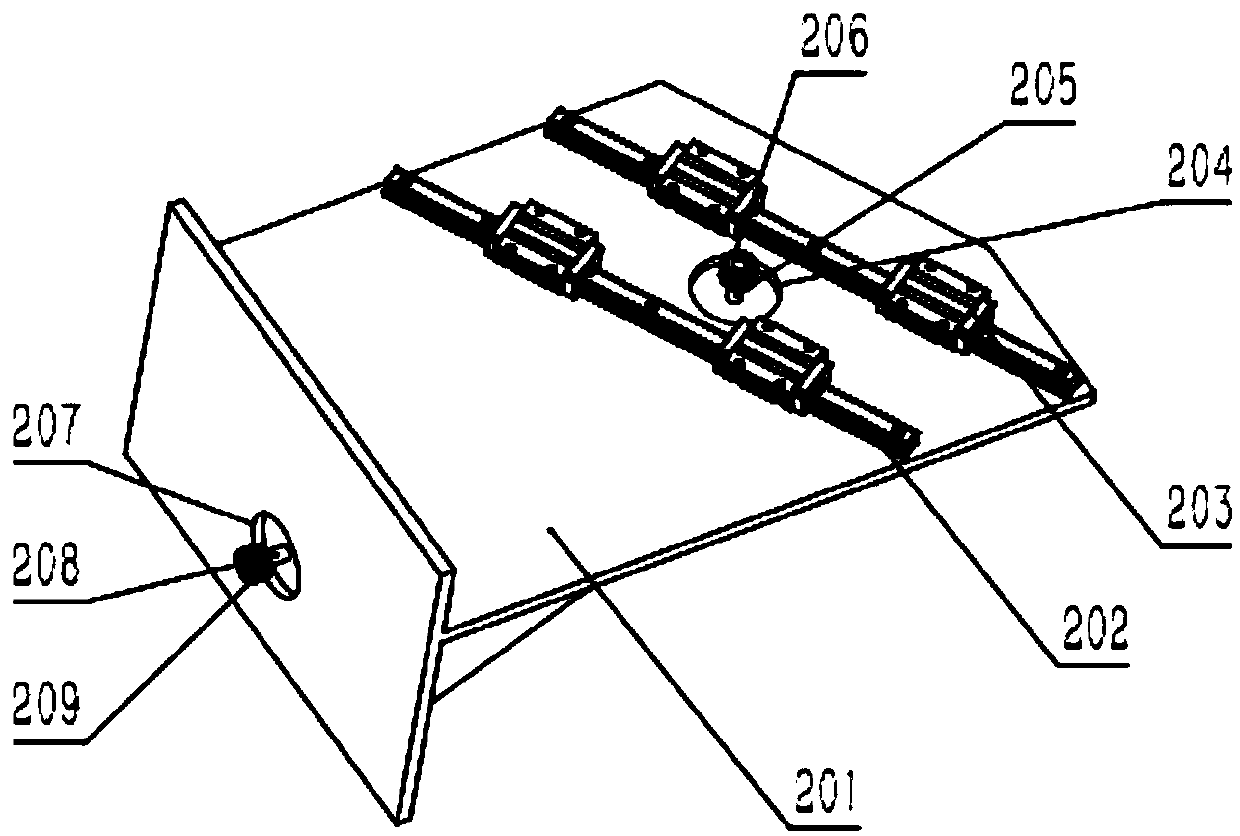

[0019] The base support assembly 5 is composed of a support frame 501, an X-direction rail 502, an X-direction slider 503 and an X-direction rack 504, two X-direction rails 502 are fixed on the support frame 501 in parallel, and four X-direction sliders 503 are installed on two X-direction rails 502 respectively, and X-direction rack 504 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com