A tubular micro-bubble generator

A technology of micro-bubbles and generators, applied in fluid mixers, chemical instruments and methods, transportation and packaging, etc., can solve the problems of micro-bubbles that cannot meet the needs of water purification treatment, poor quality of bubbles, and complex structures, etc. The pores are easy to block, the installation and operation are convenient, and the effect of improving the degree of shearing and crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

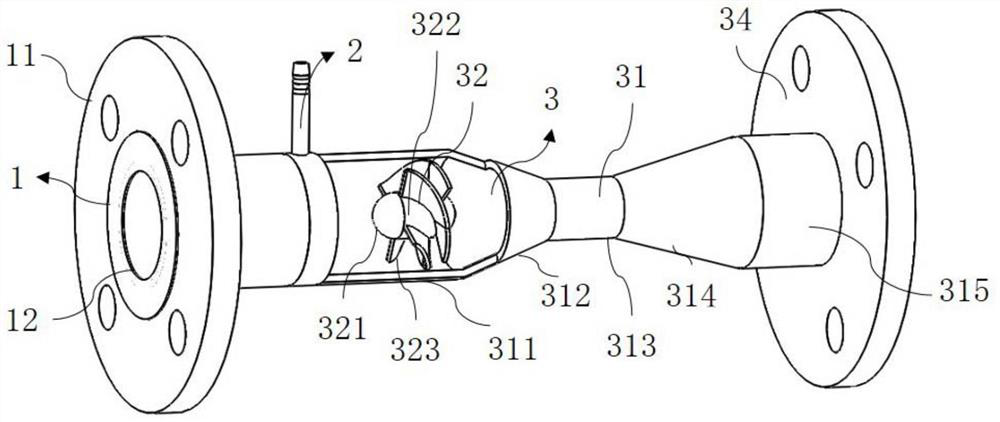

[0026] Such as figure 1 As shown, a tube-type micro-bubble generator is installed in the water purification pipeline, including a water inlet assembly 1, an annular gas injection mechanism 2 and a bubble breaking mechanism 3 which are connected coaxially in sequence; the water inlet assembly 1 It includes a water inlet flange 11 and a water inlet pipe 12. The water inlet flange 11 is connected to the water inlet end of the water purification pipeline. One end of the water inlet pipe 12 is connected to the water inlet flange 11 and the other end is connected to the annular gas injection mechanism 2.

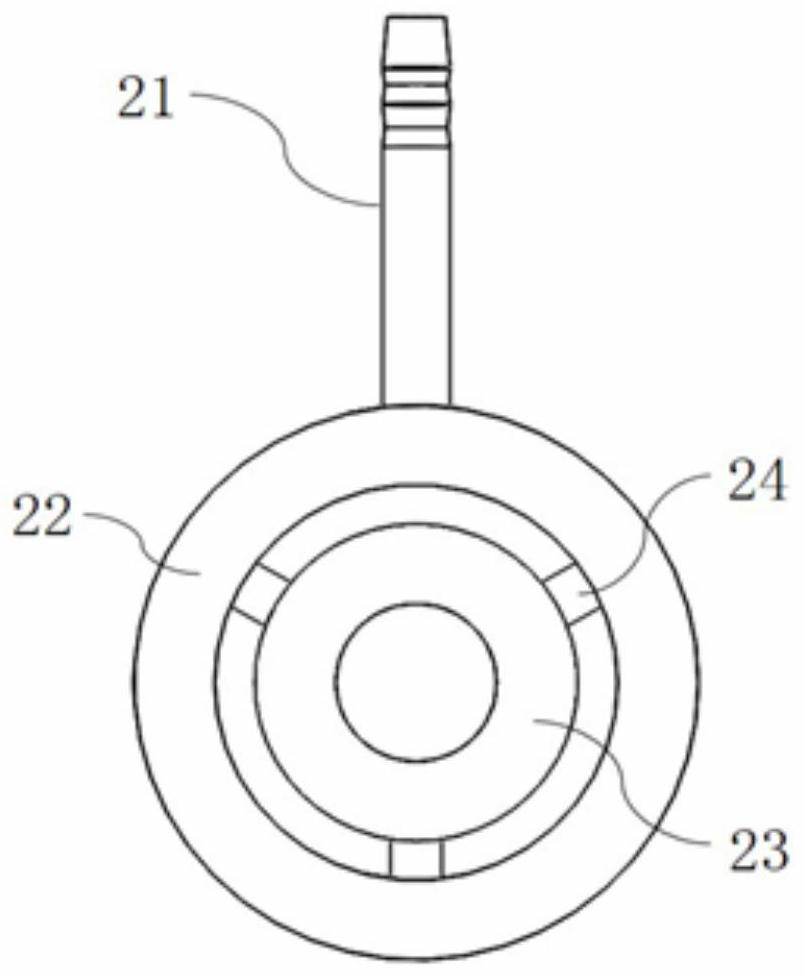

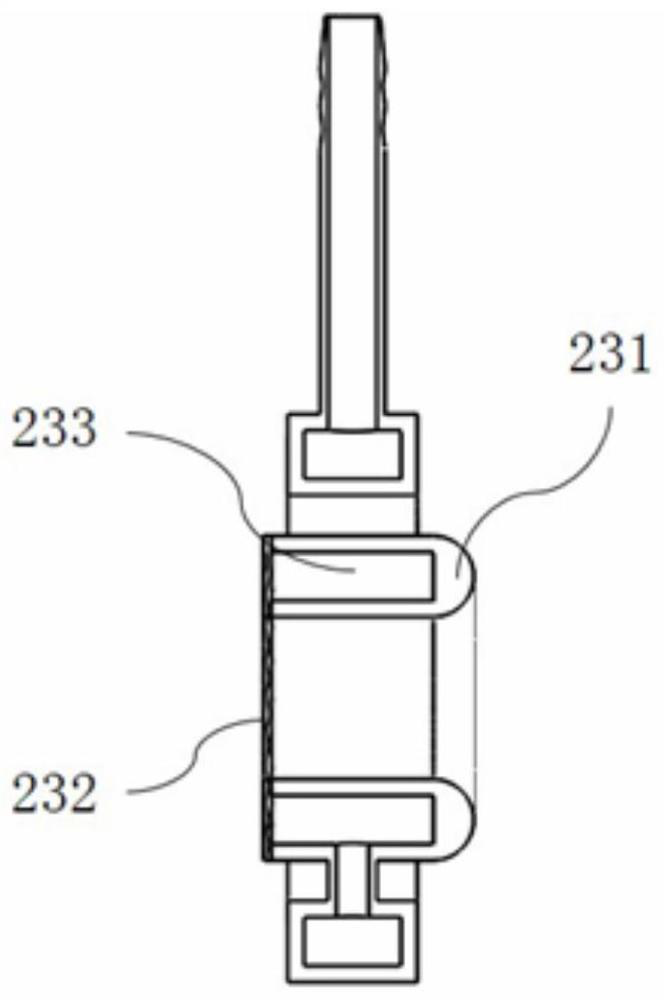

[0027] Such as figure 2 and image 3 As shown, the annular gas injection mechanism 2 includes a gas injection pipe 21, an outer ring 22, an inner ring 23 and a connecting pipe 24, the inner ring 23 and the outer ring 22 are installed concentrically, and the outer ring 22 is a cavity structure , the inner ring 23 is a ring cavity 233 with a side opening, and a microporous plate ...

specific Embodiment

[0040] Figure 5-7 In order to base on the above-mentioned design concept and structural scheme, the Computational Fluid Dynamics (CFD) simulation related display of the operation effect of the pipe-type micro-bubble generator under the specific treatment water volume was designed and developed. Specifically, the designed inlet water flow rate is 3m3 / h, the inlet pipe diameter is DN25, the inlet water pressure is 0.2MPa, the gas injection ratio is 5%, and the gas injection pressure is <0.5MPa. The figure shows the static pressure cloud diagram, velocity cloud diagram and turbulent kinetic energy cloud diagram of the bubble breaking section of the tubular microbubble generator respectively.

[0041] (1) Analysis of pressure simulation results

[0042] Figure 5 In order to intercept the static pressure distribution cloud diagram of the y=0 plane and each cross-section, it can be seen from the figure that in the Venturi flow channel, the pressure in the flow field presents a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com